Ay8452

Members-

Posts

29 -

Joined

-

Last visited

Everything posted by Ay8452

-

Hi guys, The bay window area of my 1930s house is in a bad state. The structural engineer has had a look and recommend replacement with timber (first floor) and the ground floor is fine (masonry). It's all part of a renovation of the house and we are getting new windows too. I've recently had the loft converted - am I ok to use a similar insulation spec to the dormer walls? This is what I had in mind from outside in Tile cladding (Rosemarie tiles) Vertical softwood timber battens. Provide PVC vent with insect mesh at all sides of cavity. Horizontal battens with top edge chamfered to encourage water run-off. Breathable roof membrane. 9mm external grade OSB. OSB to be fixed to studwork. PIR insulation between studs with 40mm cavity for ventilation external side of stud frame. PIR over studframe to stop cold bridging taped to act as VCL Plasterboard and skim. Is that sensible? I was also thinking of adding EWI to the outside of the house - but this wouldn't quite like up with the bay window insulation. Thanks!

-

It's above an opening into the house from the porch.

-

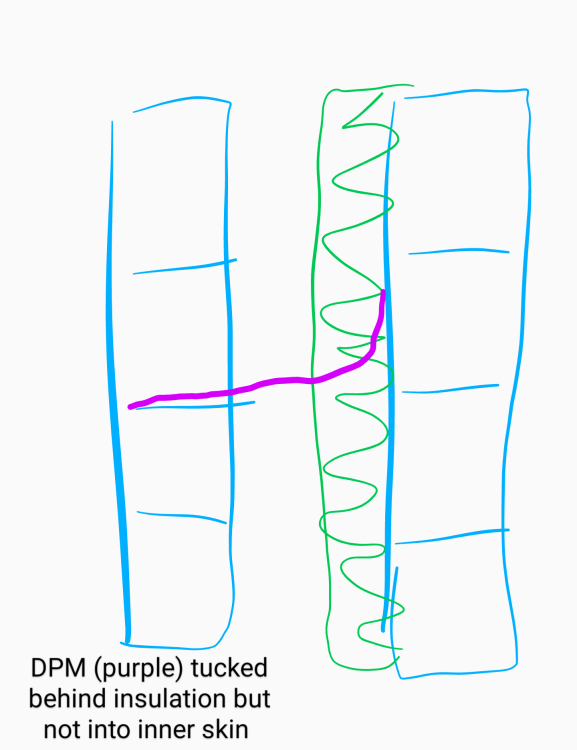

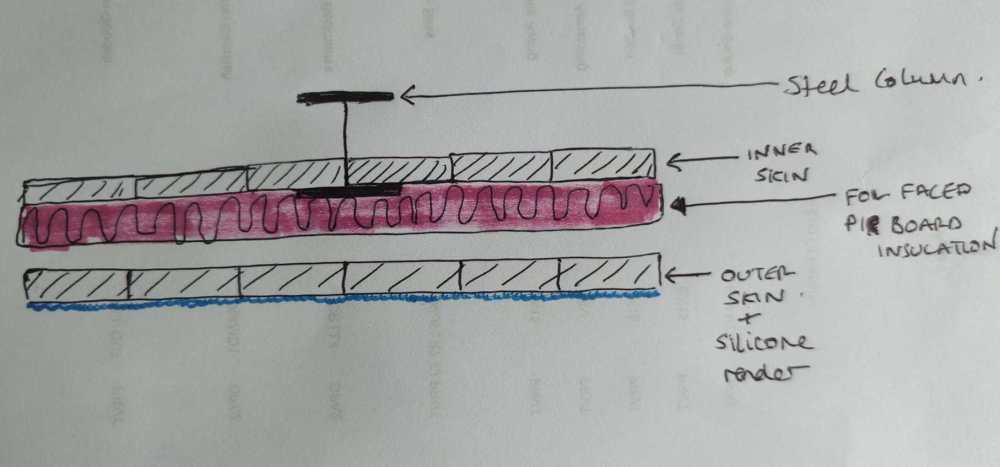

Hi folks, I am having an extension built at the moment. It's double store side extension with a new front porch.l single storey. The front porch has a gable shape roof. My drawings have specified a cavity tray above the opening from the porch into the double storey extension. It's a standard build with a 100mm inner skin block and then 100mm cavity with 90mm PIR board then 100mm outer skin block and then a silicone render finish. My builder / bricklayer forgot to put the cavity tray in when building up the inner skin but then reassured me when doing the outer skin he would use a preformed cavity tray. I've just checked and for the outer skin he has simply used DPM membrane on the outer skin which then going into the PIR board and then up against the inner skin. It's not a preformed tray. Is this a problem? I guess a preformed tray is less likely to move around but having just the DPM is going to move around especially water was going to fall on it. Please see diagram for reference. He has reassure me he's always done it this way but just seems like he's forgotten to do it right. P.s. everywhere else the cavity tray has been done the "correct" way with the DPM starting in the inner skin. Maybe I'm overthinking it?

-

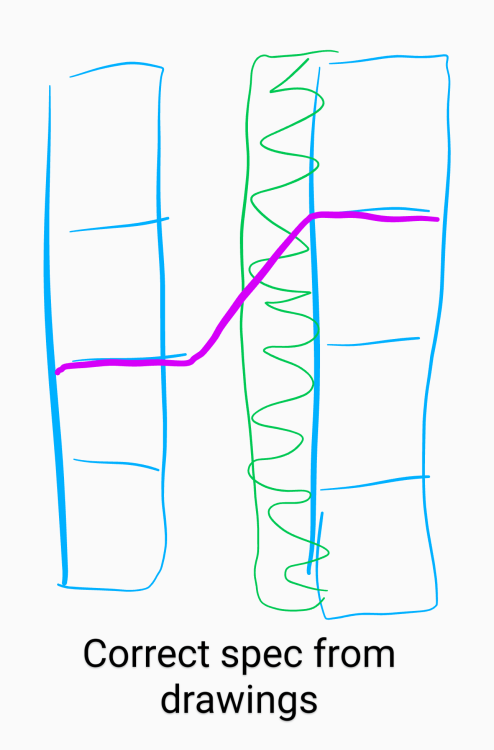

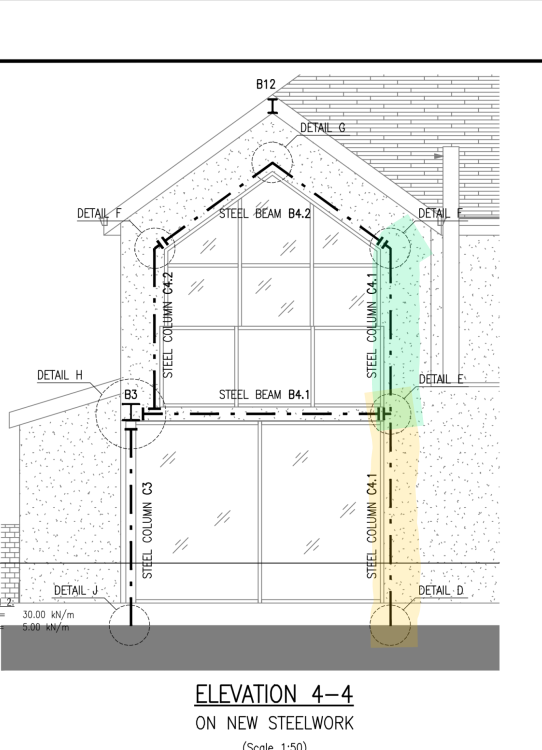

Hi guys, Can anyone advise if the quality of welding here is acceptable? The blue section was neatly done off site and supplied like this. The Green section was done on site but it really doesn't look right to me. Building inspector coming tomorrow. This is a structural element in a two story extension for a vertical steel column. Thanks guys

-

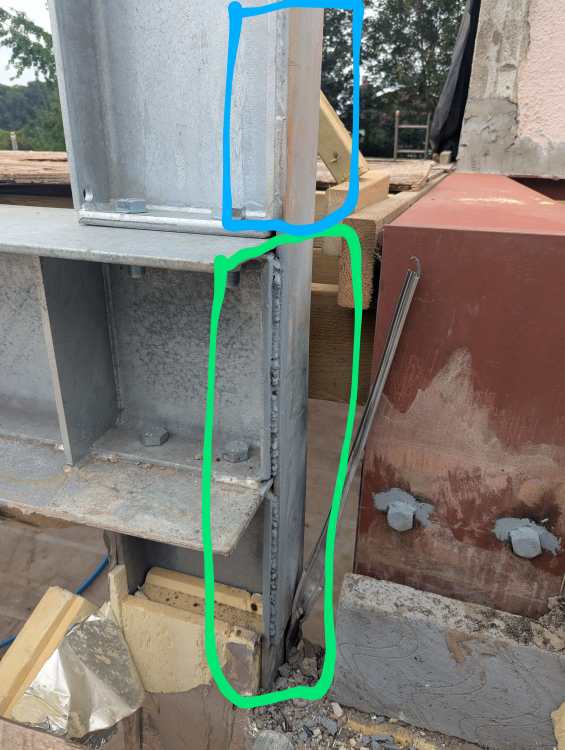

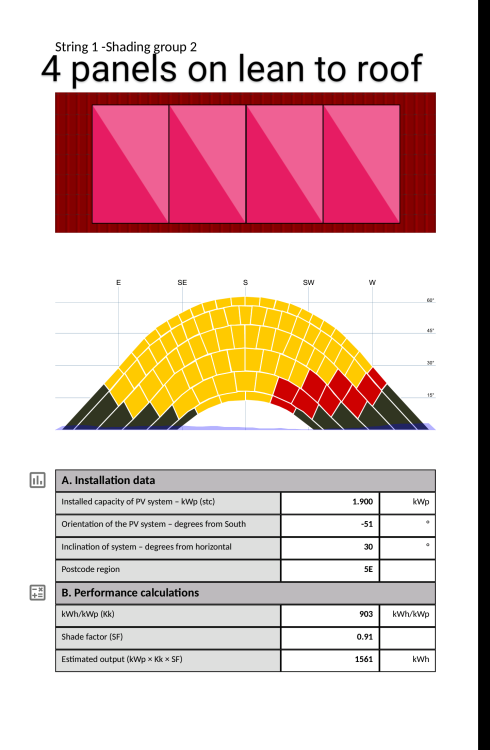

Thanks all for your replies. I agree with many, three phase just seems to complicate the solar setup + the hosue, unnecessarily. Currently do not have any crazy electrical loads. However since it's a "forever" home, I am trying to future proof it. ASHP in the future + 3 phase EV charger etc. Installer has suggested putting all 14 panels on one string all with optimisers as the 4 panels that will get heavy shading in the late afternoon won't have enough start up voltage for the inverter so essentially become useless. The 4 panels are on a single storey roof facing SE and the double storey roof is immediately above it so when the sun is in SW/W it will be very shaded on the single storey area. If this isn't a good idea, please let me know, your opinions are welcome.

-

Thank you for your reply. If ALL the panels were on the same string fitted with optimisers for each panel then it "should" negate the issue with the start up voltage right? This is what my installer is suggesting

-

Problem is I am renovating/haven't moved in yet. And I'm currently renting a tiny house which doesn't reflect useable so have to estimate for now

-

Hey folks Looking for some advice on proposals I've received for my solar setup particularly inverter sizing. Proposal: 14 X Aiko Neostar 3S 475W N-Type, Mono Glass All Black, Gen 3 Panels (good panels?) - 4 of the panels are on a separate roof to the other 10 and are heavily shaded in the late afternoon/evening. Sigenergy battery - thinking either 8kWh to 10kWh for now. Not sure if going bigger makes financial sense based on my estimated usage really? We have 3-phase supply and plan to have it well balanced (new electrics going in as part of renovation). Estimated use is 4-5,000 units (not moved in yet, we are still renovating) for a family of 2 adults and three young kids, not including future EV charging for a car doing 10k miles a year, plan to charge overnight via the Grid. For 3 phase Sig energy inverter sizing; I've had conflicting advice with some installers recommending a 6kw, 8 kw, 10 kw, and even a 15 kw. Based on my basic research 8 kw seems sensible? Questions: What inverter size would you recommend for this kind of setup considering it's 3 phase? Would 8kW be sufficient, or is it worth stretching to 10kW? For the 4 panels that are shaded, some have recommended optimisers whilst others have said not to as they go "wrong" over time - thoughts? Roof is SE facing pitched at 36 degrees. Appreciate your insights!

-

Thank you both, yes steel already installed. Should I try and get some galvanising paint on it, I can partially get my hand in and around one of the columns however the other one I have no access to...? And yes plan is to insulate/box in.

-

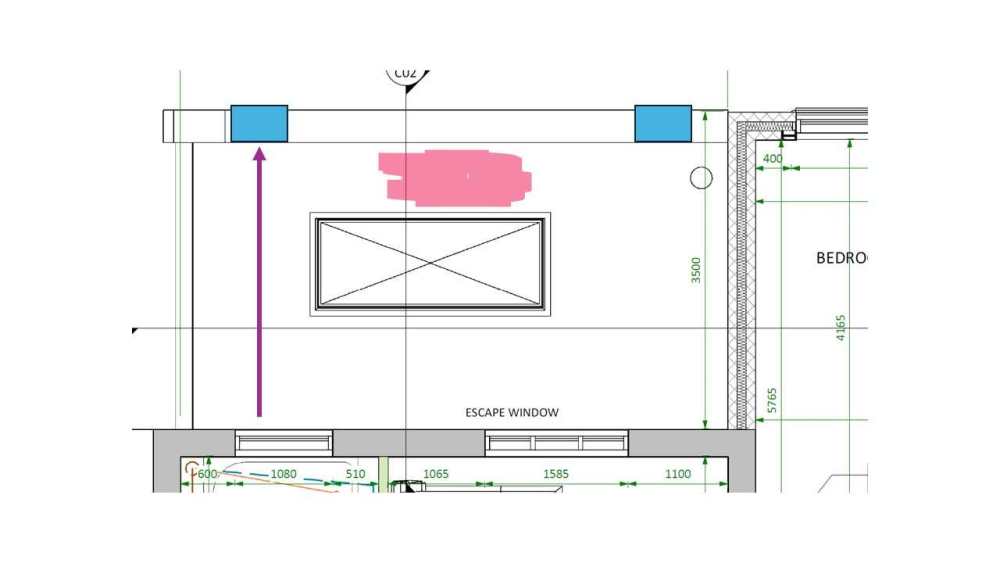

Hi Folks, Just trying to get my head round drawings from my architect for a single storey rear extension 3.5m with a warm flat roof (GRP) and parapet wall detail all around. He has specified furring strips from the old house out to the rear (purple arrow) with 2 parapet wall rainwater outlets (marked in blue). Surely the area marked red will collect rainwater, what's encouraging it to move/drain out the water outlets? Ignore roof lantern that is not going to be built we've opted against it. Thanks

-

Morning folks, I have a couple of steel beams that I have installed as part of a double storey extension. Some of these the engineer has asked to be galvanised which we have done. A few other's he hasn't or at least his drawings were not clear. These are sitting in the inner skin on the warm side of the cavity wall insulation - see image attached. Cavity insulation is foil faced PIR board tongue/groove but also taped over all joints. Outer skin is going to have a silicone render. I only had red oxide protection on these steels and there seems to be mixed review on if I need to protect these steels with galvanisation. I have messaged the engineer and am awaiting a response, I am sure it will be best practice is to galvanise but feel its overkill here... Can anyone share some guidance on this? Steels are already in and walls built to ground floor ceiling level.

-

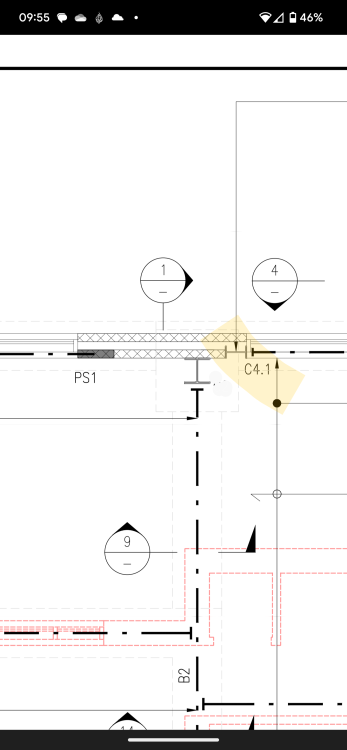

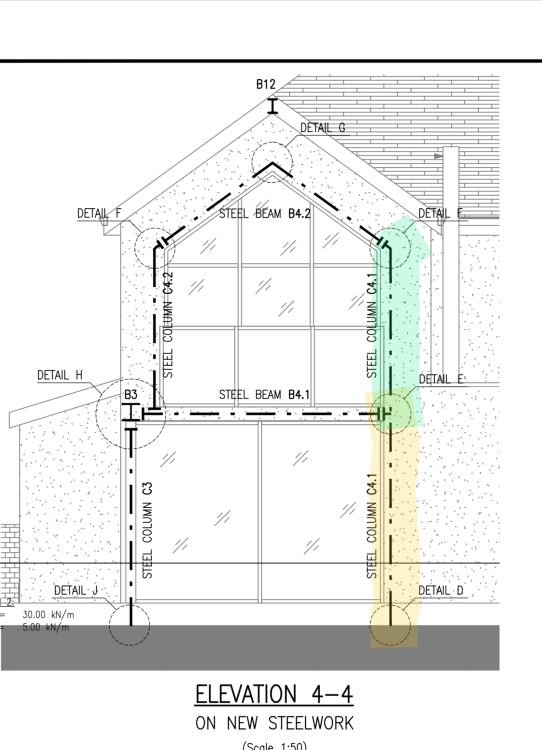

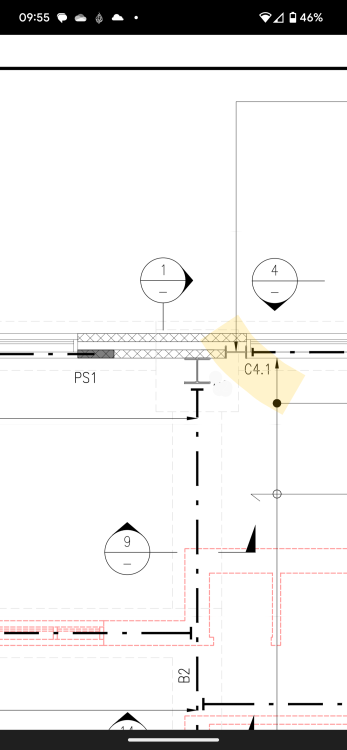

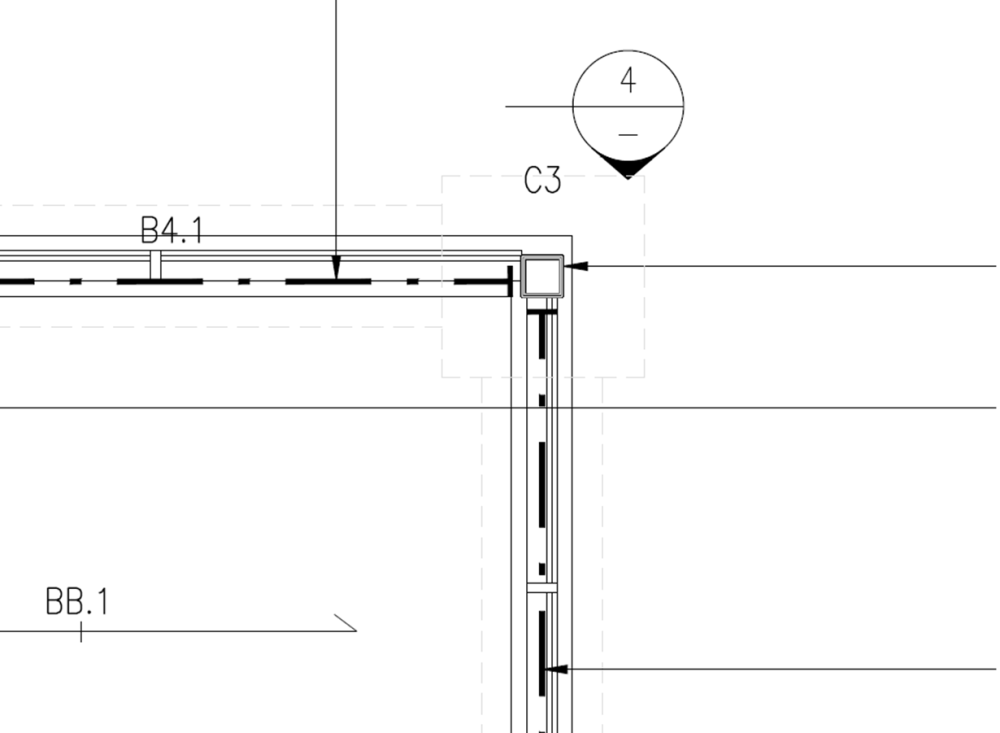

Hi guys, My engineer has specified wall ties for a steel column (C4.1) in his drawings attached. He has specified wall ties from this column to the inner skin (which we've done) and from this column to the outer skin also (which we haven't done by mistake). So there are no ties from the external skin block work to the steel in this section only. There are wall ties in the rest of the cavity wall (inner/outer leaf) as specified. C4.1 is about 300mm wide and 100mm deep. We haven't built the next storey up (highlighted green) and will make sure correct ties are used when we do. Is this a major structural issue? Have messaged my engineer and am awaiting a response. Anyone with more experience care to share their thoughts to hopefully ease my nerves. Glazing not currently fitted - so can access the cavity from the side. Could I get some sort of straps to ties to fix from the side? Thanks! P.s posted this in another section but thought this section might be more relevant.

-

Hi guys, My engineer has specified wall ties for a steel column (C4.1) in his drawings attached. He has specified wall ties from this column to the inner skin (which we've done) and from this column to the outer skin also (which we haven't done by mistake). So there are no ties from the external skin block work to the steel in this section only. There are wall ties in the rest of the cavity wall (inner/outer leaf) as specified. We haven't built the next storey up (highlighted green) and will make sure correct ties are used when we do. Is this a major structural issue? Have messaged my engineer and am awaiting a response. Anyone with more experience care to share their thoughts to hopefully ease my nerves. Thanks!

-

Compacfoam for Sliding alum doors/fitting doors to steels

Ay8452 replied to Ay8452's topic in Heat Insulation

Did you line the sides or top with something like compacfoam or is that overkill? Little worried about weatherproofing and movement here also - prefer to fix to something more solid. -

Compacfoam for Sliding alum doors/fitting doors to steels

Ay8452 replied to Ay8452's topic in Heat Insulation

I was planning on doing this also. This would essentially negate the need for compacfoam under the threshold right? Not sure if I am overkilling it with compacfoam under the threshold as well as what you've done. -

Hi folks, I am having three sets of 4 meter sliding doors fitted. Trying to do what I can to reduce thermal bridging without breaking the bank. All the doors have steelwork above to attach to and some have masonry at the sides and some have steel at the sides. The threshold thickness is 110mm and my cavity wall spec is silicone render outside, 100mm block outer, 100mm cavity, 100mm block inner. Anyone have any pragmatic suggestions to reduce thermal bridging? My current plan is - Line the openings with compacfoam and then Fit the sliding doors through the 20mm compacfoam at the sides and at the top and where possible at the bottom threshold (already built this up with masonry for some doors so may not be able to), and then weatherseal this externally/clad with alum to match the door frame. - OR line the openings (sides and top, not bottom) with timber 25mm timber to act as a thermal break and fit the sliding doors through this. Does this sound sensible or is this overkill? I am having an insulated external render system (EPS) over where the steels will be a cold bridge. Just thinking if I am overdoing it. Thanks

-

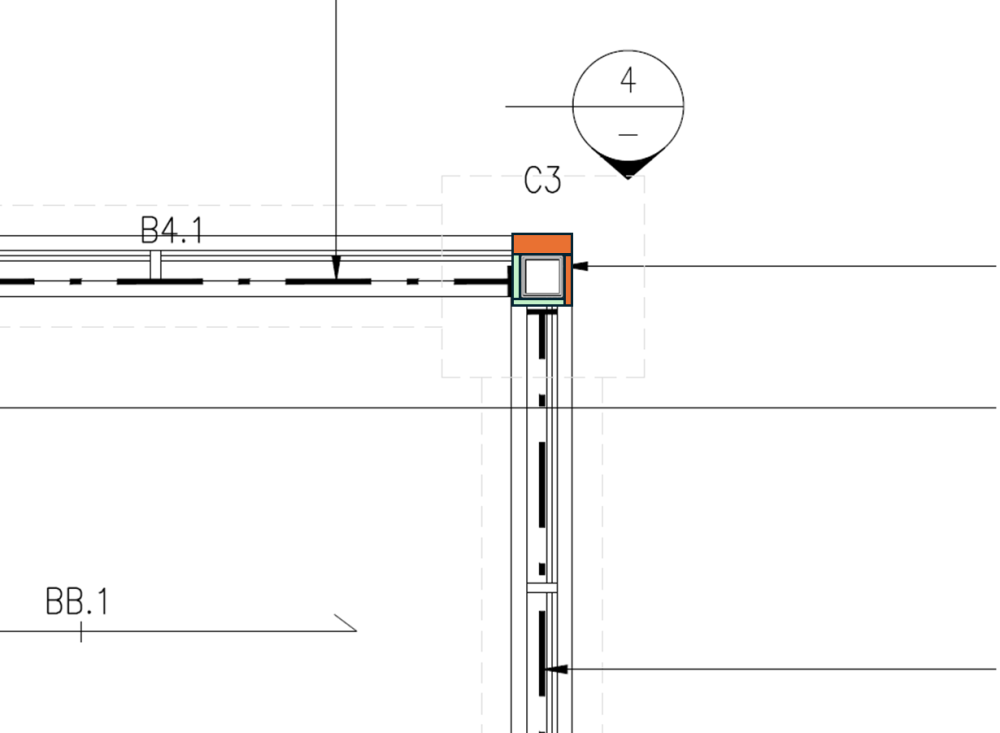

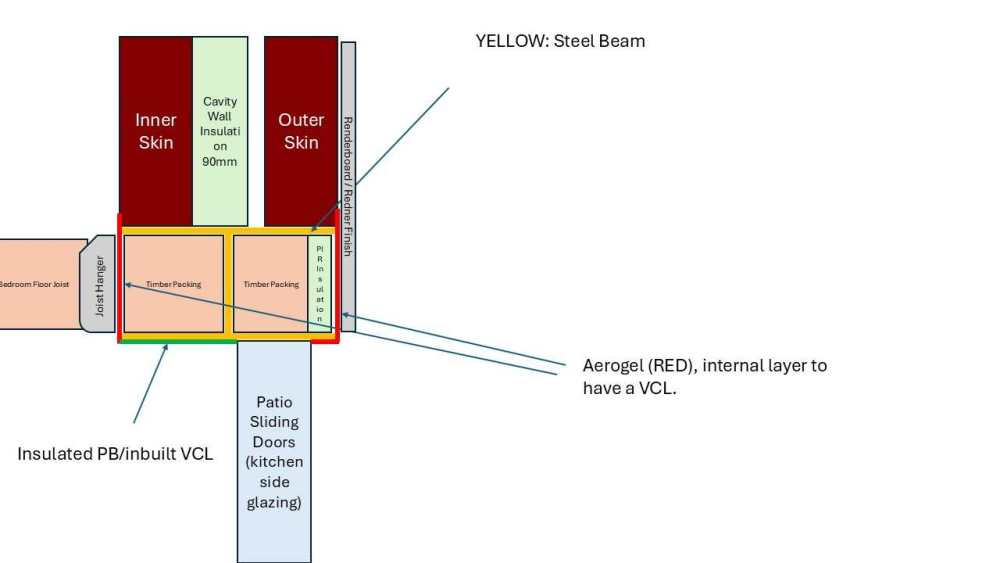

Hi folks, I have a steel 200 x 200 corner post as part of a corner set of sliding doors. Had a read of very useful previous threads Looking to insulate this and was going to do the following 1 - on the external two sides place PIR board (any specific type I should use as it may be exposed to the elements?) or EPS board 2 - Internal two sides place vertical strips of aerogyl as space is a premium here (the corner post is inline with the the inner leaf for one wall and then cavity centre for the other wall, therefore I have more space externally hence use of PIR board/EPS in that location) 3 - wrap the post in a VCL (any recommendation on a brand/type?) 4 - clad the steel post with timber 5 - Fit sliding doors/Alum cladding around post Does this sound about right? Should I just stick to one type of insulation and sue aerogel? See pic below of my structural drawings Then added my insulation below (orange being EPS/PIR) and green being aerogyl.

-

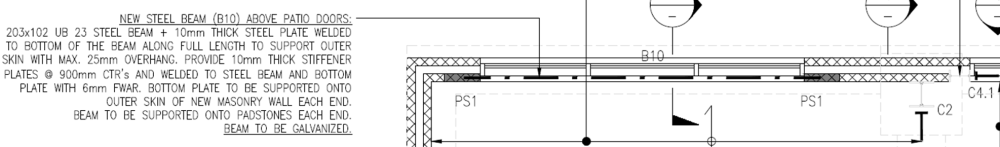

Hi guys, My engineer is on holiday and would be grateful if someone with more experience can help me here. For the bottom plate on this beam, where it says 25mm max overhang, does that mean, A - the blockwork (outer skin 100mm) can overhang the bottom plate by max 25mm so only 75mm is supported by the actual bottom plate B - OR does it mean the bottom plate can extend MAX 25mm past the outer skin blockwork? For reference, wall spec is 100mm blockwork inner leaf, 100mm cavity, 100mm blockwork outer leaf. Thanks!

-

Hi everyone, I am scratching my head on how best to insulate this steel. I have posted before and think I've tweaked the spec that will work better. It is already installed and is a big cold bridge. The timbers haven't been installed yet, I am thinking of using aerogyl but it is very pricey. Does this sort of spec seem ok? Can I fit the joists through the aerogyl into the timber packing? Spoke to aerogyl supplier and they pretty much advised trying to wrap the steel in aerogyl at every surface where possible. Is there some sort of external insulation panel I can use/render over instead externally? Thanks

-

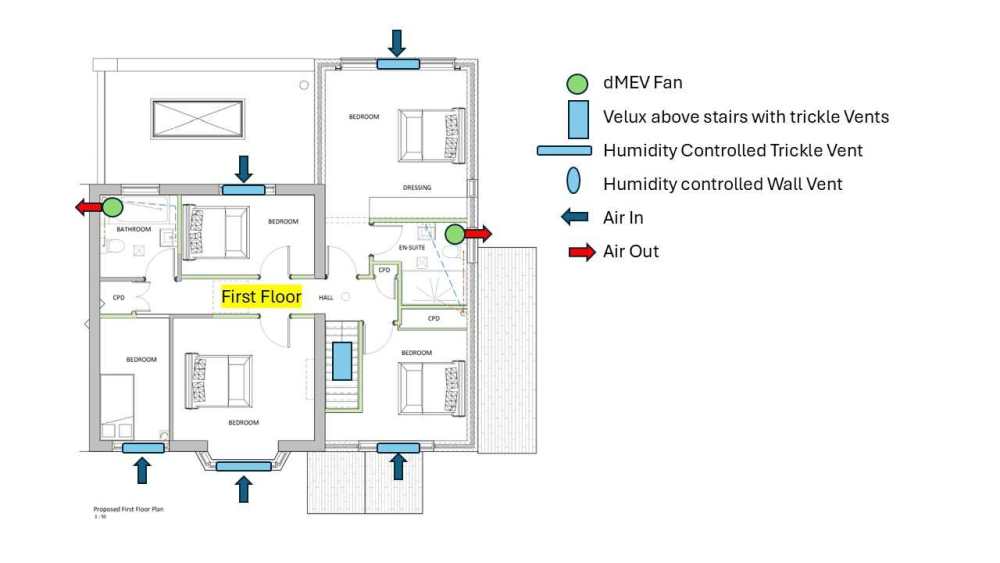

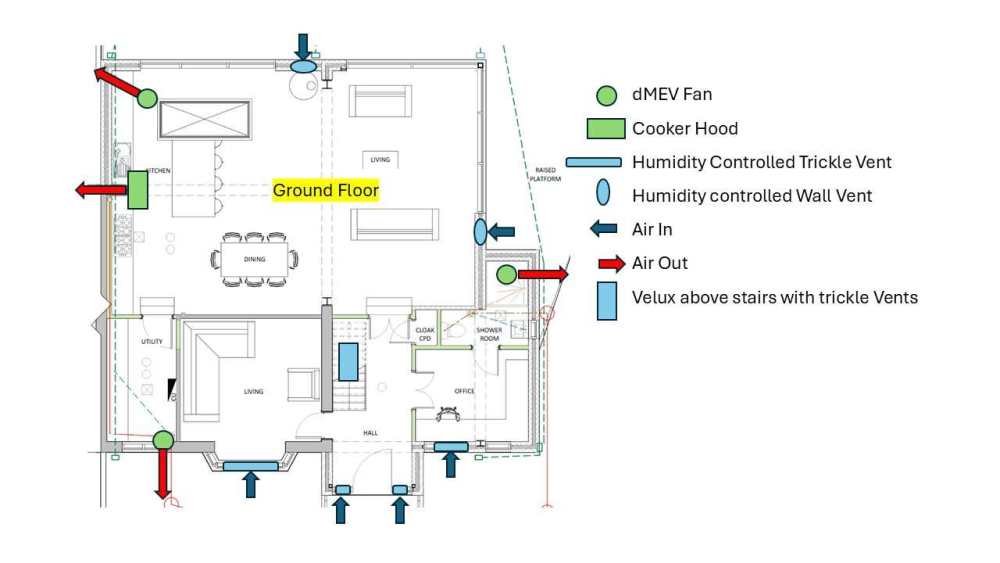

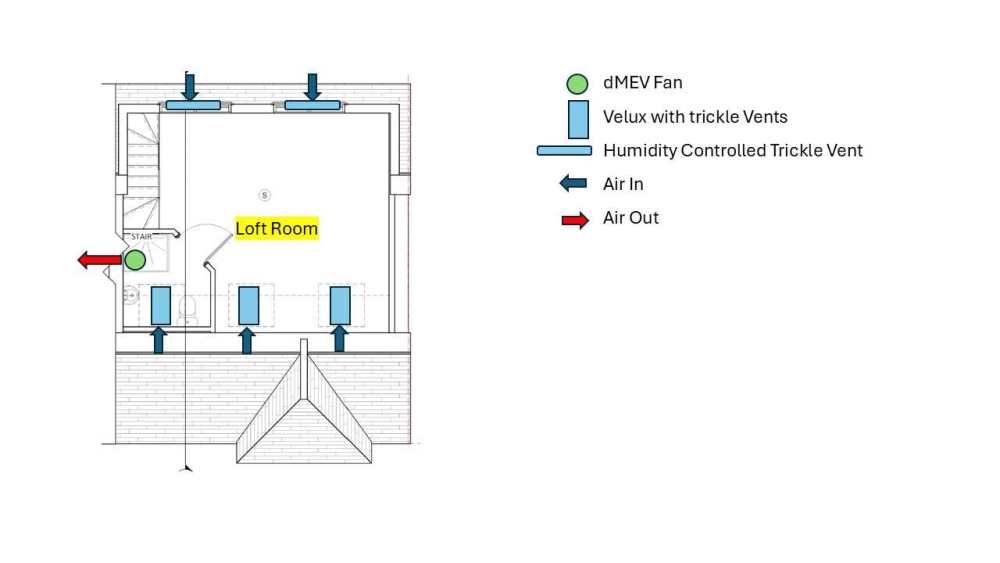

Hi all, I am looking at ventilation options for my renovation/extension project. It's a 1930s single wall house which we are extending to the rear and side as well as a loft conversion. The airtightness of the existing house is probably going to be pretty poor whilst the new part will be better. I have ruled out MVHR for now partly due to cost but also I just don't think we will be airtight enough. I am looking at dMEV or a central MEV with extract for all wet rooms (4 bathrooms, 1 utility, 1 kitchen) and then humidity trickle vents in dry rooms. - Is there much difference between dMEV vs central MEV in terms of ventilation performance and power use? I prefer central MEV just to avoid making 6 holes in the fabric of the building for 6 dMEV fans however most central units (aside from high end ones) cannot zone areas so if one bathroom is being used, all 6 wetrooms will go into boost mode which seems like over-ventilation/needless heat loss (?). - Can anyone recommend a central MEV unit, better yet one with zoning? Duco do the DucoBox Focus that can zone but is pricey vs other units especially by the time you add the relevant sensors etc it gets closer to MVHR money. - The kitchen/living open plan space won't have any trickle vents as the sliding doors are thin frame/we want to avoid them. I am looking at putting in humidity controlled wall vents - anyone have any suggestions of what they have used? Looking at this one at the moment; https://www.bpdstore.co.uk/glidevale-fresh-99hdb-humidity-sensitive-acoustic-wall-ventilator/p/232 - Please see my proposed plans below (loft stairs not shown but they are there!) Does this seem reasonable? I have looked into dMVHR but not convinced the technology is that great. Heat recovery is pretty low and again a unit in each room is pricey = close to central MVHR money. Appreciate the help! Ali

-

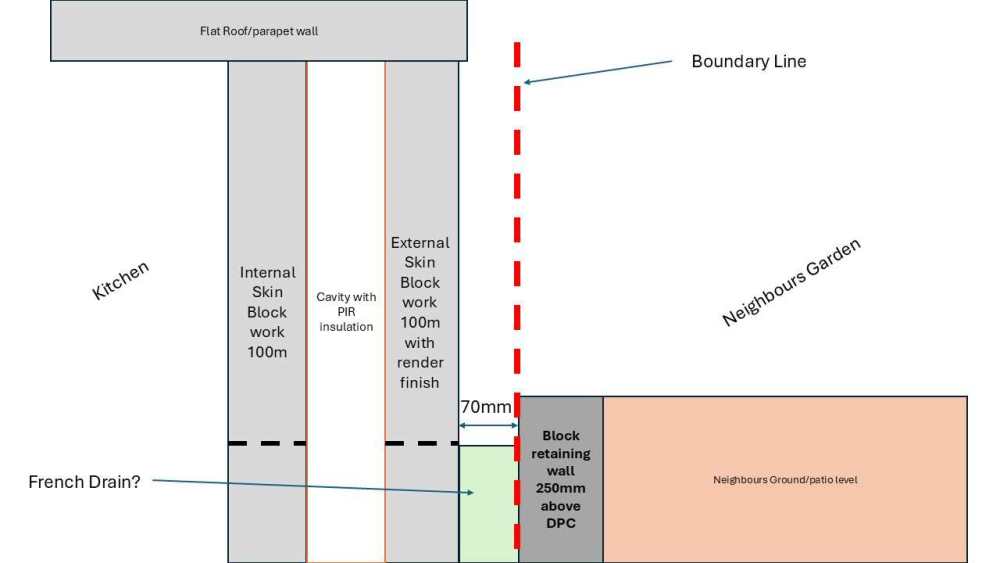

Hi guys, I am having a single storey extension on my house and trying to find a suitable solution for the following problem. On the side elevation with my adjoining neighbour (semi-d house) their ground level is approx 25cm above my DPM level. I am having beam/block floor in my extension. I have a 70-80mm gap with their ground level. If i out a french drain in here and "tank" the wall with something will that be enough to prevent problems? How deep should the French drain be, 15cm below my DPM level? Drawn a diagram as though I am looking back at the house from the garden, at the rear elevation. Foundations are in and blockwork is about to start. Final spec is cavity wall with render finish. Thanks Ali

-

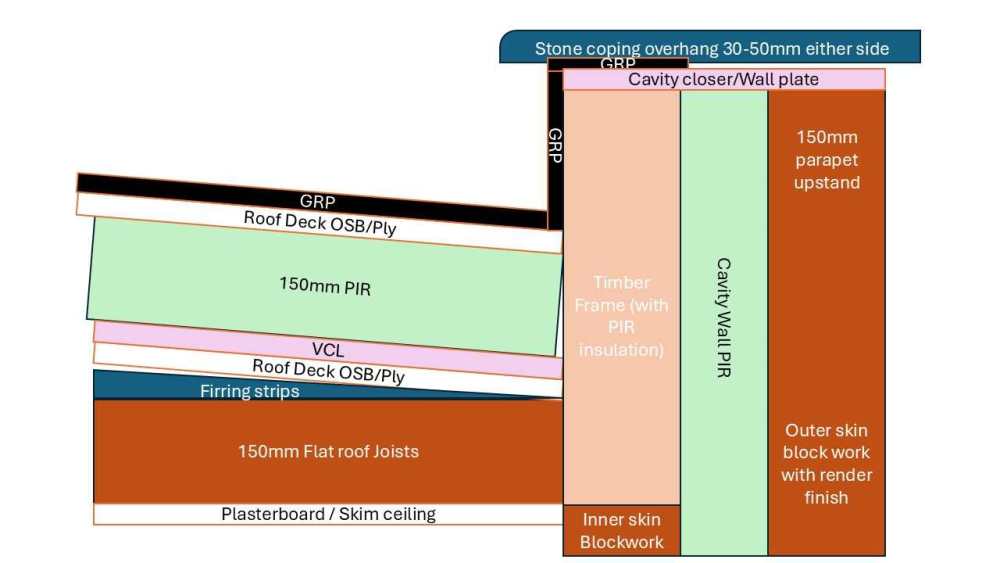

Hi Folks, I am doing a single storey extension which was originally specified for a cold flat roof/parapet wall detail. I want to change this to a warm flat roof/parapet wall detail partly because I am going to be adding EWI to the old wall the roof is going to be attached to. Just so I can figure out if I have the correct spec/thickness of everything - is this diagram broadly correct? I am hoping I have enough height to change to a warm flat roof. Will take this to my roofer and designer next week to ask if we make this work over a cold flat roof. (building to current building reg's, foundations in and walls up to DPC currently) - Am I correct in understanding the minimum height f the parapet wall from the external roof deck/GRP is 150mm? - I have going with timber frame for the inner leaf for the parapet wall to eliminate the cold bridge, is this sensible? Thanks Ali

-

Thank you for your response - why the bitumen paint first?

-

Hi Folks, I am doing an extension/renovation of my house. I have a few steel beams/columns. I have found a way to bring most/all the steels into the envelope of insulation (warm side) in terms of walls/roof. However I have a few columns that go through the block/beam floor structure and of course the floor insulation (150mm PIR). Steels going through the floors structure - is that as bad as a cold bridge as them going through the walls/roof? Steels are already in so in order to avoid issues I guess the only thing is to wrap the steels in PIR/tape OR aerogyl but it seems overkill/overspend to do that. FYI Steels are in, Beam Block floor is going to be fitted over the coming weeks, there will be a 500mm void below the beam and block. Thanks! Ali