Peaklander

Members-

Posts

46 -

Joined

-

Last visited

Everything posted by Peaklander

-

Large screw type piled decking foundations

Peaklander replied to Post and beam's topic in Landscaping, Decking & Patios

My decking was installed over twenty years ago and is in great condition. It is exposed to sun and wind (it's about 1m above ground level) and I think this helps. The piers sit onto concrete pillars in the ground (holes drilled with a huge auger). I treat it every few years with Hicksons Decor wax (sadly now ceased production). -

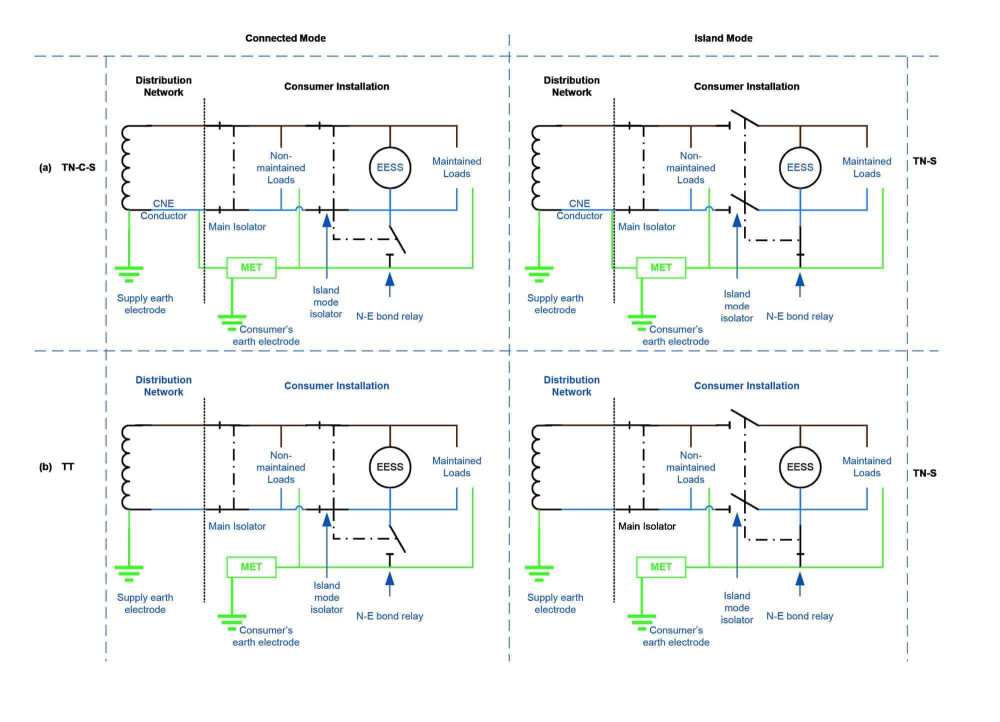

I'm late to the thread. I have a pair of Sunsynk 3.6kW inverters in parallel. They provide the 'signal' for island mode across a volt-free contact, if you have also ticked the box in the settings to enable the feature. You monitor this with the external contactor that has been mentioned, letting the contactor couple the N & E when island mode is signalled (during an incoming power loss). On some Sunsynk inverters I believe that the VFC closes on island-mode but on my smaller inverters it opens. Therefore I need to use a normally closed contactor pair, so that when the contactor drops out, the N-E connection is made. As for providing a local earth, you need to supplement the DNO's earth because during a power loss you can't assume that their's will remain. So assuming that you aren't already on a TT system with your local earth rod in place, you need to provide one. This can stay in circuit and does not need to be switched out in normal operation. This IET article refers but here's a diagram from it... https://electrical.theiet.org/media/1549/earthing.pdf

-

Yes, I posted a pic of the inlet side of the pump but said that I didn’t have one of the H. The pipe was cut out and the crud cleaned out and then it was connected back in. Plumber #2 did that and I was cleaning the header tank.

-

Big thanks to @marshian for sharing the details of the old pump that I sent him. It really does explain a lot. To recap, I’ve not had any involvement with my parents’ heating until recently. So I’ve no idea if any inhibitors have been added over the years. It was another family member who noticed that the rads weren’t getting warm enough and as I live closest, it was me that went to look. That was after a plumber had been and suggested a failing pump and possible ‘air-lock’. Venting over wasn’t happing as far as I know, until I replaced the pump and even then it wasn’t noticed immediately. It had been drained so that a couple of trvs could be changed. Refilling was slow as we couldn’t remove the air easily. Only when plumber #2 and I decided to try a flush did we then see the vent-over happening. He didn’t comment on the short height of the U though. As we had enough heat for Christmas and NY I waited and called him back to open the H pipe. That was after plumber #3 quoted £5k to replace the whole system with a combi “the only way to fix it”. So to conclude, a bad design that somehow had never had vent-over and poor maintenance of the system which slowly filled with crud until a better pump highlighted the issues. I would never have got here without the help of you on here. Thanks to all.

-

It’s yours. Let me know what you want to do.

-

Yes 28mm around the bottom of the H on the boiler flow to pump and 22 up to vent with 15 down. i don’t know how long it has been since a drain-down or what chemicals have ever been in.

-

Yes got one.

-

Hi, here's the update. We cut the H pipework out, releasing it on the top side of the pump inlet valve. Popped a hosepipe below the cold feed isolating valve and emptied and cleared the header. There was plenty of gunk just in that, obviously most sitting on the bottom and sides under the water level. The inlet side of the pump was choked though. I don't have a pic of the H pipe as I was in the loft but that did have residue on the pipe walls. After this was re-instated the partial refill that was needed seemed to go better than previosuly and there was no pump-over at PP2 pump setting but still a little at full bore. So I asked plumber to lift the vent which he did. I'd already told him that I didn't want to retro-fit a pressurisation vessel. There was no pump-over after that at CC3 but in fact I left it at PP2 and all was well. The header had got some brown water in again from that brief pump-over and so I'm resigned to another full drain and flush/fill - but not until the summer. It has some Fernox P3 in for now. I need to leave it and give my parents relief from the to-ing and fro-ing. Thanks again guys for your sage advice and comments. It has been very helpful and gave me confidence to stand my ground and not do the pressurisation and certainly not rip the whole lot out and replace for £5k

-

A quick question, if you were me, would you still replace / inspect if possible, the H pipework? I don't think I now need to introduce the pressure vessel in place of the header. I'm planning to lift the vent pipe U and drain / refill after cleaning the header.

-

Plumbers 2 & 3 did. Don't know about #1. Thank you for all the help. This thread proves that often all of the detail is needed before a cause can be found.

-

Yes well it wasn't me it was Plumber #1 that said to swap the pump and sometimes I do listen. It can be a fine line to tread when a DIYer interacts with a tradesman. 😊

-

I didn't try it earlier because I was distracted by my Dad. Later I felt that maybe PP1 will be too slow and I can't be there to check over the next few hours. So I have come home to go to a 50th wedding. It will be good now until Tuesday when I am going to be steered by what Plumber #2 wants to do. However it could be as simple as lowering the water level. I did bend the float arm but couldn't bail any out as that's when Dad felt odd and I had to check for stroke and heart (I am not a medic). Also there is scope for the vent to be raised. Maybe that's all we end-up doing on Tuesday.

-

Yes the yellow leds flash on those variable speed modes - just needed to catch it right with the phone otherwise they are OFF! I haven't gone to PP1. I will leave until Tuesday and I suspect that Plumber #2 will want to remove the tank as I said. I think I can risk that. Screwfix have the parts ready for me to pick-up. My job will be to bail-out the header although as it's circulating around anyway, perhaps I can let most drain out first and then bung it up.

-

Ok some pics plus my father is having some sort of issue which I’m keeping an eye on. This is the first setting and the water flow over. This is PP2 with reduced water that sounds worse than it is. That just means I should have looked and not listened. There is scope to lift the height of the vent. Edit. Obviously the water colour is still not good and it will need a further clean.

-

I changed the pump and I will double-check the valves when I go there this morning. Plumber #2 says that they are very fragile, having sat there for years and they can break when operated.

-

Sorry about not mentioning the "few cm" before - it's been on my mind and I sat there this morning scratching my head and thought about it again when I saw your reference to 2m. I will go to the house in an hour or so (need to give my parents enough time to get up and going) and post a photo. I can obviously bend the float arm down a bit, in order to lower the water level. The tank is pushed tight against low rafters and there's not much scope to lift the bend on the vent. It must have been a finely balanced set-up and then I came along and changed the pump. Rather than go your combined feed/vent @John Carroll, Plumber #2 wants to remove the header and set-up an expansion vessel with PRV and fill loop. We have discussed it and will do it as long as we just set a very low pressure. I don't want to find any leaks in the pipework. He will re-pipe the H anyway and the vessel will physically go in place of the header but I will examine that H cross-pipe to see what I can see. I'm starting to think that the sequence of events was: 1. Lack of corrosion inhibitor and no mag filter, caused some sludge and a little gas to be formed that probably turned into an airlock. This caused the boiler to constantly trip out and in, without getting the radiators to heat. 2. Air removed and pump changed and system cleaner and filter added. 3. System flushed, sludge removed and all ok except the pump over. 4. The new pump has highlighted the lack of tolerance there is with such a low vent to water level differential.

-

The vent pipe bends over just above the header tank. So it's just a few cm above the water level. I don't have a photo but there's not much room to accommodate a rise in the water level in the vent.

-

Yes but here the vent is behind the pump, on the other side of the cold feed tee, just along the horizontal pipe in the H. So a restriction there can divert but I’m not so sure of one further along the system. However we will see. I hope! Edit: just seen the comment by @marshian above. I don’t think it’s been happening for long but something caused the initial problem of air or airlock in the system and lukewarm rads. and that was before the pump change obviously.

-

We fitted a mag clean a few days after the pump. I cleaned it after a week and it did have some gunge and a few steel flecks. The HE isn’t having any trouble keeping the CH plenty warm enough throughout the day. As for restrictions, I can understand how one at the tee at the cold feed / H pipe can divert flow up the vent that’s just before it in the flow circuit but I can’t see how a restriction further round the system can do that.

-

Yes that's a good call. I had already looked at the link you sent a few days ago and I can see that they are available next day. So yes, that would be the next step.

-

Location is middle Peak District. I did the pump change myself. I usually do things correctly but I will check tomorrow and I will also test the other pump modes too. I have just got Plumber #2 lined-up for Tuesday and we will investigate the H together / clean out the header / check the pump valves are clear. Also he told me at the pre-Christmas visit that he would like to remove the header and replace with an expansion / pressure vessel, PRV and a cold fill pipe. I might well get those items 'in stock' so that if we go that route I have it covered. However the @John Carroll mod to tee the cold feed to the vent is an easy option that I will suggest.

-

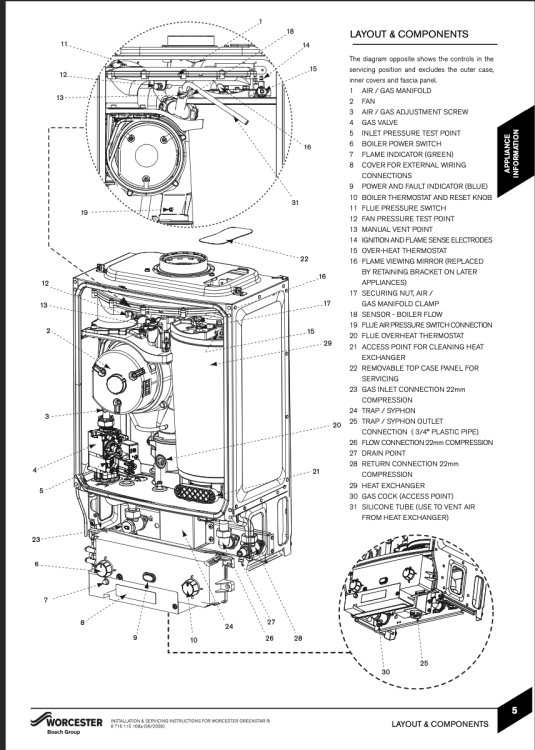

I'm not there now but there's no internal pump. The best I can do is a screenshot of the page in the manual. Also I appreciate that I might be incorrectly setting the pump mode and so I will go in the morning and try again and gather evidence! I could put the old pump back... Also, I have just spoken to the plumbing company rep. who visited this morning (I'm sure he's a plumber too BTW) and asked why the HW tank has to come out and why we can't "replace all the H pipework". His answer is that with the full job, the problem would be solved and without it, in his experience, "it's never satisfactory". He said that they wouldn't be interested in the pipework alone. I would like to rid myself of the problem (and so would my wife), as I have been trying to keep things going since a couple of weeks before Christmas and then this week into the New Year is a nightmare for getting anyone interested. I can go to one more company on Monday (who access to several plumbers) and perhaps get a final assessment. I don't want to redo the H pipework myself but I could. The only things I need are a 28mm cutter and the pipe & fittings. My parents would also pay the money for the 'full solution' but something says that's just wrong. I guess it's down to confidence that it's the H pipework only. After all, the radiators all get hot so why not?

-

What do you mean John?

-

Thanks for the feedback; I'm not surprised by it and it seems to be sensible. I did try the PP2 setting this morning but again only for a short time. The noise from the vent water sounded louder from the bottom of the loft ladder, so I changed back to the (slow) CC1. This is the pump that was replaced. And the new one

-

Of course - I should and do know better. OK, well now I have seen Plumber #3 and we had a good chat which started with me explaining the timeline and steps taken. Then he had a look around and finally gave his verdict. He thinks that looking for a restriction is not going to be fruitful and instead wants to change to a combi system. So new boiler, remove HW tank and the airing cupboard pipework and the pipes to the DHW and CH headers. The HW tank comes out "because that might be restricted". (It can't be IMHO as the problem is there when the DHW is off and the zone valve is closed). The common flow pipe into and the CH flow out of the airing cupboard will be cross-connected and a small towel rail rad will go in there, T-eed from the flow and using the existing bypass return pipe. The combi can pick-up on the existing boiler position but the DHW feed-out needs to connect into an existing DHW pipe 2-3m away, running through an understairs cupboard to T into a cloakroom sink supply and the rest of the house. That's not too difficult. A new 22mm gas supply pipe from the meter will be run (about 15m, some outside) as the existing is 15mm. It just seems to be an overkill but I would be able to step away. Cost is £5k. I think the alternative is to partially drain, remove pump and the isolating valve above it, cut the lower right leg of the H, release the header (and take away to clean it) and then be able to examine the H for any restriction. Plumber #3 solution just does away with the H pipework, doesn't sort any CH circuit restrictions that there might be, unnecessarily removes the DHW tank - but does provide a Building Control certificate which would possibly be useful when the house is sold (parents 89 & 97).