tokyotecubate

Members-

Posts

26 -

Joined

-

Last visited

Everything posted by tokyotecubate

-

Hello! We just obtained consent for a sewer connection to an existing thames water sewer manhole. The existing sewer pipe level is more than a meter deep in the manhole, where our sewer pipe does not reach that deep in following the 1:40 flow ( it will be at most 40cm deep by the time it reaches the manhole. Having consulted most plumbers, the normal way to do it is to do an internal backdrop to bring the pipe to the 1m level of the main sewer pipe, however I read on the guideline from thames water that they do not recommend so - I wonder if anyone here has done a direct connection to a manhole, and whether we really do need to put the backdrop ouutside the chamber? Doing so would entail a LOT more work from the plumber ( and from what I saw, quite unneccessary work as well, as the manhole chamber is Huge and the internal backdrop would not restrict access at all) Keen to know your thoughts, and generally from your experience with thames water about this. Thank you!

-

Yes there is water coming out, just that the water isn't heating up ..... I am going to the build this weekend to extensively test this again 🤞

-

thanks for fixing my typos - rage typing ( fuming with our heat pump installer due to extensive delays and multiple unresolved issues! ) surely doesn't help 😬

-

Hi all, A bit of background - we are currently renovating our house and had new pipework installed alongside a heat pump as our main source of heating. The plumbing for the whole house was set up by a previous company who unfortunately aren't around anymore. The heat pump is just installed ( not fully commissioned) - however, on testing the hot water throughout the multiple taps in the house, we realized that some taps are not getting hot water. ( this is the first time we are testing the new plumbing in the house) What could bee the cause? Is this caused by the individual tap fitting? Our fittings are mixer cartridge and are concealed valves, which would be a nightmare if we do need to check the cartridge. The heat pump installer said that it could be either the mixer taps, or it could be concealed valves on the hot downservice pipework ( though honestly I am not too sure whether I fully trust this as we had had multiple instances where they weren't being fully transparent with the problems of the install). Are there any ways to check the fitting and the cartridge without needing to cut the tiles ( as honestly it would be a nightmare to do so just to check if a cartridge is working properly) Just the thought off how to troubleshoot this is giving me nightmares. Any input is welcomed - Thank you!

-

Concealed shower valves too recessed?

tokyotecubate replied to tokyotecubate's topic in General Plumbing

yes it has - is it bad / unacceptable? what should have been done, and is there anything we can do to rectify it now? -

Hello Folks! Posting a question not related to the technical aspects of heat pump but more related to contractual management of heat pump installers. We are in the process of installing a heat pump - the installation was planned for Jan. Prior to the installation, the installer has conducted at least 2-3 technical surveys, and have specified requirements prior to the install ( such as having a levelled base for the outdoor unit, etc) As with most building projects ( we are in the midst of a reno), the installers has requested some further accomodations ( such as moving the air vents for a MVHR unit, needing to further level a floor for installation of thermalskirt heating, etc) - they were all only raised when they were on site, and for their requests we generally have been swiftly accomodated ( we called in other trades to do the floor levelling and got that done within days, the ASHP engineer came out and removed the venting within the same week, etc). Other than the affected areas, there were plenty of work to do ( such as connecting the pipework for the thermalskirt heating in the rooms, setting up the outdoor unit), where the installation team has not attended to ( for example, the scheduled installation period was for a whole week, but the team would only attend 3 days before being called on to another job). We have also observed that the installation team have generally not been the most efficient when they are on site, constant chit chats, shoddy and incomplete installation work, etc The installation was supposed to be tested and finished by end of Jan, but they have not been back to complete the rest of the installation work, where their delayed thermalskirt install is a main blocker for all internal decorating work ( such as painting). They were multiple incidents of them having committed to come out to do work, and them not having came out. For example, the latest committment was for them to come out the past friday and saturday, only for us to receive communication from them, after having called the project manager multiple times, that they are not coming, on a friday afternoon at 5:30p.m. During our call on friday, the manager has committed to his team coming out on Monday and tuesday, and that they will be finishing the thermalskirt installation and testing by end of this week. Prior to the committed install for today, I messaged their project manager the day before to confirm again on his team coming out to do the work, while also urging him to arrange his team and prioritize the work this coming week, he messaged back, late at night, pointing fingers at the so called 'delays' are due to our works not having progressed sufficiently ( which I know is a lie, as I was on site and can confirm that they had been dealt with long ago since early Feb - they just don't arrange the team to come out to finish it, and also did not bother to communicate any planned attendance or progress with us). He also had the guts to tell us that he plans to charge additional 'materials' cost, when the scope and the design of the project has not changed ( to which the quotation should have included all related materials and labour cost to the project). Throughout the project he has also never communicated to us about any additional material costs. ( hence this is all a surprise) I would love to hear your thoughts on where we stand in terms of these delays with the installer - I understand that they are MCS certified, and also part of RECC - would they help to interfere if the installation gets delayed beyond an acceptable timefrrame? How do we stand against the so called 'extra materials' charge, when the design and the scope has never changed? Thank you so much for all your help - much appreciated. P.S in terms of payment wise, they have structured the payment so that we have paid more than 90% of the payment that we need to make, and the remaining payment is only the government grant, along with £500 from us for the final commissioning. Not ideal, I know - Not sure how do we stand with RECC under this payment structure? Do they only protect the initial deposit?

-

Concealed shower valves too recessed?

tokyotecubate replied to tokyotecubate's topic in General Plumbing

yes we should be able to get access from behind as it's a plastered stud wall, seems like the way to do! One thing - does this mean that we will have to reconnect the pipe connections to the valve when we 'push' it out? Would we still be able to cut the plasterboard for the valve when we try to acess it from behind? hopefully this could be fixed within a day. Thank you for all your comments and looking into this! -

Concealed shower valves too recessed?

tokyotecubate replied to tokyotecubate's topic in General Plumbing

thank you for sharing your experience! I wonder if there are any extensions (or similar products) to enable the taps to protrude more? -

Hello all! We have a set of plumbers from out of town who have set up our concealed shower valves during our first fix, where our second fix for the bathrooms are to be completed by a different set of plumbers locally ( long story behind this setup - we have commissioned an energy renewable company to upgrade our heating to a heat pump, with which they will also be setting up our first fix plumbing - turns out the plumbers they uses are based out of town and it's not really feasible to ask them to come all the way down for our second fix 😬) While our local plumber conducts the inspection of the fist fix plumbing before the second fix plumbing, he pointed out that the current shower valves are located way too deep, and are too recessed to be connected to the handles and taps. He says that it would require a reconnection of the valves, which requires us to also open up the walls and all the plasterboard behind ( which we have already decorated and painted. This seems like a lot of work and a bit excessive for just to connect to the taps? From what it looks like, the plasterboard and the tiles itself are already taking up more than 20mm, so I am not too sure how much futher can it be protruded out? You can see the pictures of the current set up below. ( the product is this one: https://www.screwfix.com/p/swirl-melba-rear-fed-concealed-satin-brass-multi-head-shower/480kh) Would love to hear your suggestion on how to tackle this too - are there any easier way to fix this, other than cutting the wall behind to reach the setup and reconnecting everything as the plumber suggested? Thank you!

-

Yes absolutely - I came across the product at Grand Design Live, and since we are doing a whole house renovation with heat pump installation, I jumped on the opportunity to use this instead of the traditional radiators - much better for room planning without the wallspace needed for the radiators. They are now fitted together alongside our heat pump - some companies do offer that as an option ( with add on) rather than the traditional radiators, though not all of them offer that ( I, for one, know that british gas and octopus does not offer that) I have still yet to try it out, will definitely come back for a more detailed review once we have moved in and test-ran it ( which we hope can be done in time before winter is over )

-

We are having a renovation and our builders have put in new boards for all the floors - by the time we come to fit the skirting boards (we are fitting thermalskirt), we just realized that the floors are not levelled. On consulting the builder, he said that the job for floor levelling is not part of the job for setting the new floors (?!?!), and that we have to find some other way to level the floors. (i.e we got a massively unhelpful builder) I think some self-levelling compound in that area could work - I know it works for concrete floors, but not sure if this could work on wooden floorboards too? If we were to find someone to do it, how much should we expect them to charge (the area is around 12m2), and how long would it take to fix this? Thank you!

-

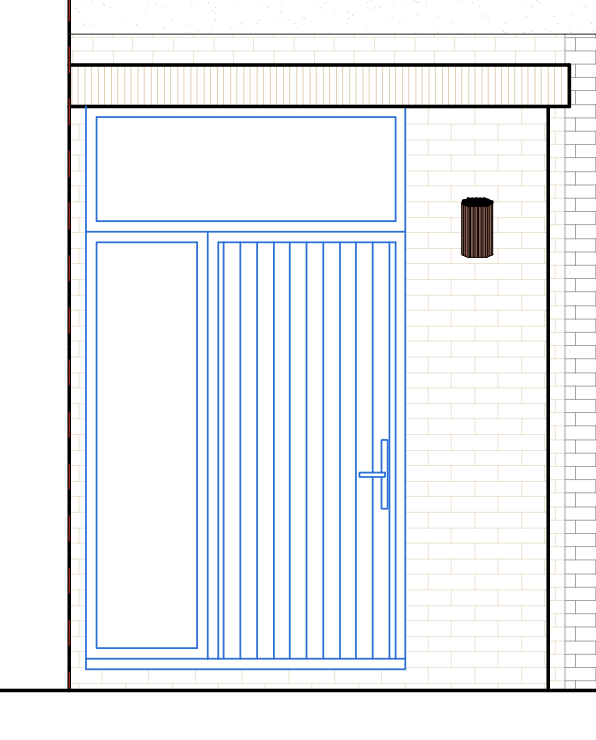

Hello all, We are planning to demolish our existing porch due to subsidence, and is planning to put a new replacment porch. The design of the new replacement porch will follow the exact requirements outlined for permitted development ( <3m2 in area, less than 3m in height, our house is no where near a boundary of a highway), however, it will follow a relatively modern design ( brick wall with a glass entrance door set), rather than the traditional edwardian porch that was in place. ( our property is an edwardian property). Please see attached old and new proposed porch. From what I know, as long as the porch falls within permitted development, then we should be able to go ahead and start the building work, but of course, it is always safe to get a certificate of lawfulness. We had done an extensive renovation and had obtained all planning permission and permitted development consent from the council prior to us starting work - from our experience of dealing with the council, we realized that the planning officers are extremely conservative in our council ( we have had a previous submission for permitted development for the loft refused based on their opinion that our glass pane is too big!) I worry that, shall we were to submit for permitted development with the council, we could get rejected again for some silly reason, and that would meant a lot of pushback to our project schedule in completing the renovation, and moreover making it hard to build the porch design that we like, even though it complete falls under the permitted development guidelines. Since the porch is such a relatively small thing, and given that the existing external door will still be in place behind the porch, would you say that we would need a certificate of lawfulness for this? Will this be something that would be required when we sell our property down the line? One thing worth to note - our area is subject to consultation to become a conservation area, so it might also be worth to get the certificate in case it does become a conservation area? If you were me - would you go through the trouble to submit for permitted development with the council, or just go ahead and build it? Thank you!

-

Holes on plastered walls behind kitchen units

tokyotecubate replied to tokyotecubate's topic in Plastering & Rendering

Thank you! if our builder is going to fill it up with sand ( as shown ), would we need to put flexible conduit over the wires? Thank you! -

Holes on plastered walls behind kitchen units

tokyotecubate posted a topic in Plastering & Rendering

Hello all, Would love to seek a bit of advice regarding to a plastered wall that will be behind some kitchen units. We are going to have our kitchen fitted on this wall as shown, where our electrican has to unfortunately make some holes to chase the wiring in. On our request, our builder has patched up some of the holes ( as you can see from the patches on the wall), but has left the holes on the wall as shown. We worry that those holes will be problematic down the line, as insects and dirt can be trapped behind - I wonder what are your views on that? Do you recommend us patching those holes around the cables? We also notice that the decorator has done a pretty bad job in filling up the holes as well - from your opinion, should we insist ( or even find another decorator) that could do a better job that this? Would this in your opinion be needed, as kitchen units re going to be fitted on this wall? We are going to be fitting this on Monday so not sure if there's much we can do about this - appreciate all your advice on this! -

Mould on new plaster - what should we do?

tokyotecubate replied to tokyotecubate's topic in Damp & DPCs

@nod and @Conor - that is great news! So basically letting it dry out, wash the mould out with bleach, and then it's good to paint? On another note - any advice on how to deal with builders who drags and delays your job? better to find other trades and move on? -

Hello all! Happy New Year - Wishing you all a great year ahead with trouble-free builds. We have been undergoing a full house renovation over the the year, where our builder has plastered our walls at around early December. We have been away for around 2 weeks in December to visit family, and when we came back to see the house and the work that was conducted, we were shocked to find the new plastered walls in our utility space ridden with mould ( see attached) The wall behind the plasterboard is the original brick wall, where the plasterboard is being dot and dabbed onto the existing wall. I wonder what could have caused the mould, especially since it is a freshly plastered wall? Is it because the plaster was not dried well ( the builders might not have applied enough heat and ventilation to dry the plaster), or is it because of some inherent problem, like rising damp? Would it be a leak? ( there should not be any pipes behind but on top of this wall is where the new extension meets the existing wall - see attached joint detail of the flashing above that wall) I've read that the plasterers should apply the primer onto an existing brick wall before applying the dot and dab to prevent existing damp to transfer to the plasterboard - does this seem the plasterers might have skipped this step? Would be very grateful if you could advise us what to do about this wall - would we need to remove the plasterboard and re-plasterboard + skim the area, and what should we do to prevent this from happening again? Speaking of - to pile on top of this problem, our builder has gone AWOL since christmas. We have observed them putting much less men ( and many times, no guys) at all on site, despite them having missed not one, but 2 extended deadlines for move in ( we were supposed to be in end of August, with the deadline being shifted to end of November, and now they cannot even meet a new extended deadline of end of December for only key tasks, such as painting and tiling). When we asked them about the much less progress and men on site since end of November, the builder claims that he will be working over christmas, and that the key jobs will be finished. When we came back to the house after christmas, the house was in such an incomplete state that it was far from anywhere close to completion. In other words, we cannot rely on our builder and will have to find other trades to finish up this job, and to fix this mouldy plastered wall. What should we put out as a job to fix this, and approximately how much should I budget to fix up this bit of wall? Thank you so much, and looking forward to hearing your experiences ( both in dealing with mouldy walls, and to deal with rouge builders)

-

Hello all, We are supposed to have our kitchen delivered today, however when the kitchen delivery company arrived, they claim that they do not have access to the site and the site is not ready ( our builder has laid their shelf with the tools in the hallway), and left the site without delivering the kitchen. The kitchen company is now charging us £520 for the redelivery charge, which to me seems pretty ridiculous - that would be the cost of the fitters for a whole day! In all fairness, while our builders should have kept the site access clear, the delivery company never gave us a timeframe, nor give us a call when they are near site. They show up 8:30am, took pictures of the access, and just left. Our builders were planning to clear the access for the delivery thinking they might arrive in the afternoon. What would be a fair cost for redelivery charges for a kitchen delivery? ( Or that you know other kitchen companies charge for) - £520 seems very steep ( and a surprise as they never gave us any of that coat when we bought the kitchen !) Thank you!

-

Forgot to mention, we also have a half installed UFH system that their plumbers still need to install - again, my builder can finish the UFH in time for flooring installation next week, but then again what will happen with the warranty if that happens? We absolutely need to have that UFH completed in time for flooring installation next week, which will govern our kitchen install on the 18th. What a nightmare 😭 any advice on this would be much appreciated.

-

Thank you both! Yes the ASHP is part of the MCS scheme - I believe that gives them the legal obligation to finish off the job? The company is a big company with strong financials so they would have the means to finish the job. I've talked to different installers and it seems that the best way to this is to get the installer to follow through with the job - however with their current lack of communication, this is likely going to drag on for several months and we don't have the capacity to wait around as we have all other trades booked in to finish the plastering and kitchen installation. Luckily we have withheld the milestone payment as they have not finished the first fix yet. Here are some of my follow up questions: - for electrical work, my builder's electrician could potentially finish the job. Would they generally be able to certify the other work that was initially set up by the other electrician? - how would the warranty work in this case - the renewable company offers warranty on all install, but if we have to bring in someone else to finish the job, then legally who would be responsible if anything goes wrong? - same for the HP - I believe the company is legally liable to finish the job? However, we don't want them to drag this situation in forever. What are our rights to make them finish the job on time within this month? ( On the contract it does states that installation would complete in 30 days, which by now is already way beyond that timeframe) - in general - what would you do if you were me? Let them drag on, or just terminate immediately and find a new company ( which at this point is still an unknown about whether other trades would take this half-finished HP install) Thank you so much for all your advice again!

-

Hello all, Thank you so much for all the collective wisdom here, as a first time renovator I have been stalking many pages here throughout the past months. I currently have a tough situation with my first fix electrical work for my renovation ( which involves a full house rewire alongside a full house renovation and loft / rear extension). I have commissioned a renewable energy company, with whom is doing my heat pump installation, to also conduct my full house rewire and plumbing works. While there had been delays and hiccups in the first fix completion due to their internal change of project management, they had been sending their subcontractors to complete the electrical and plumbing first fix works as per contract. However, one of the biggest problem we now face is with the electrical subcontractors that they had sent out - after 9 visits, we noticed that not much work has been done (i.e the subcontractor has been dragging the work), with the electrician being extremely difficult to work with (such as not showing up as promised, showing up late and leaving early, substandard work, and not completing a lot of the work that was promised during his visit). We unfortunately had to flag the problems with the project manager of the renewables company (who is not based locally and cannot be on site to manage the sub contractor), and they decided to terminate their electrical subcontractor, and instead send their own in house electricians to complete the work. ( this happened back in early october when we flagged all the issues to the renewables company) This is where our current problem lies - we weren't given any updates on the status of the first fix works from the renewables company, where our builder and ourselves have assumed that the majority of the first fix work has been completed. However, as my builder starts to board the house to prepare for plastering, he notices many confusion with the socket locations, alongside multiple missing socket / switch points. To prepare for plastering work, I had asked a close electrician friend of mine to do some inspection work on the current status of the wiring, and was shocked to realise that the current wiring for the kitchen was no way near ready for second fix ( there is no wiring in place for the ovens, dishwasher, fridge, sockets, etc). The first fix is completed at around 85% at best. We re now stuck at the point on how to proceed - this is the current situation: - the renewables company is not based locally, and has been extremely vague about when they can send their electrician out on site to complete the rest of the work ( they initially advised that they can send someone out on the 4th and 5th of November, but then after trying to hound down the project manager to confirm on that visit, he then mentioned they cannot send their guys down on those dates due to a scheduling conflict. ) - Our builders have already scheduled the plasterers to come out to plaster this week based on the previous assumption that the first fix will at least be completed by 5/11. - All plastering needs to be completed in time for our kitchen installation on 18/11 - if we were to wait around for the renewables company to send someone out, it is almost certain that we will need to hold off plastering - with the trades being booked up before christmas, there is no way that the project can be finished before Chrstmas, and with the holidays, this mean at least another 2 months of delay (and hence 2 months of extra rent and expenses, which are in the thousands) - The other option is to find another local electrician to complete the rest of the first fix work, though at this stage we aren't even sure if there are any other electrician that would pick up and certify someone else's work. With this situation, what would you do?

-

Sealant around sliding doors

tokyotecubate replied to tokyotecubate's topic in House Extensions & Conservatories

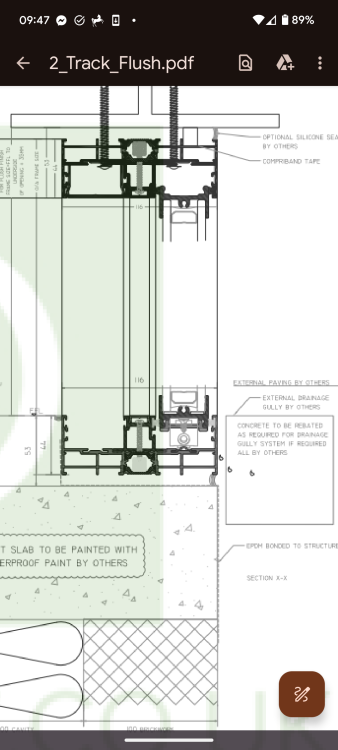

It is confusing right? We also have no idea how it can be fixed like that as well. @Redbeardthank you for your comments, you just made me realize how badly installed this is. The blaustrade is going to be fixed on the reveals on both sides( in front of the sliding doors), and hence will not need to be considered for the fixing at the bottom.( Ie it will just sit on top of the cill) I asked the installer about the current gaps ( and the current set up) and he says that this is the final finish, and that the EPDM layer is the waterproofing layer. He has planned no cill, and apparently when the installers are on site, they say that there is a 'gap' between the frame and the opening, and this is the way they fix the gap. There is the same gap on the top of the doors too. The current details is definitely not the cross sectional details that they had on their product website ( I had been badgering the supplier / installer to give me the actual details since having paid the deposit but no details were ever provided, so can only base this on the drawing I downloaded off their website.) We have requested a new install, and the installer says he will add a 25mm tall cill that will sit underneath the sliding doors when we do the new install. Does that sound like the right plan? Would love to know the usual detail and finishes for the bottom of sliding doors for the dormer to ensure there is no water ingress. Though to be honest, the fact that the installer can claim to have finished a 'job' leaving a detail like this is extremely alarming ( especially after having to bear with their last minute no show for more than 6 times!) - would you say we give up on this installer, and just find a better one that can do the right job? Thank you so much for your help! -

Sealant around sliding doors

tokyotecubate replied to tokyotecubate's topic in House Extensions & Conservatories

Thank you for all your comments and help! @Mr Punter @MikeSharp01This is the bottom of the door from the outside - my builder has pointed out that there is a huge gap ( as in his whole hand can go through ) on both the bottom and top of the doors, and we would need a window cill to ensure there is no water ingress. I've asked the door supplier about adding the cill, and this is his reply: With your pitched roof detail we would normally sit on the lead. There is not enough space beneath our doors for a 25mm sill and the 25mm sill will not have a sufficient flat surface to take the triple track of the sliding doors (210mm) and your balustrade. Epdm that the doors are sat on acts as a sill and will prevent water getting into house. Potentially could get a aluminium sill pressing made (just a 2mm thick L shape of aluminium) to your sizes. This would just tuck underneath the floor track and could be a preferred aesthetic.' But again, I still don't understand how there can be such massive gaps underneath the doors? Does this mean this requires a total reinstall? What should we do? ( P.S we have had multiple problems with this glass supplier/installer, where they had multiple instances (more than 6 times!) of missed planned installations, etc. at this point quite frankly we are not confident at all with the work, but just wanted to make sure with you all about whether their claims of just having the EPDM layer is enough, and whether even having those gaps underneath the door in the dormer is normal? ) Thank you all again! -

Sealant around sliding doors

tokyotecubate replied to tokyotecubate's topic in House Extensions & Conservatories

Sounds great - so looks like nothing to worry about? We noticed more sealant bulging on one side and less sealant in some areas in the middle, are we safe to assume that this is normal? As re there any tests that you recommend for us to test water and weather tightness of the install? Thank you so much! -

Hello all! Happy Monday! We had our sliding doors in the loft installed last Friday - I couldn't be on site as that day ( as the installers have continuously rescheduled our installation, with myself having taken 5 work days off previously just to wait for those guys 🥲 so I didn't take a day off work to be on site) After installation, when we were on site to check out the windows, I noticed that the sealant around the edges looks pretty weird - does it look normal? The 'bluging' around the edges looks pretty weird to me. Granted, it will be plastered over, but the 'chunks' seems pretty weird. As a novice, I honestly have no idea 😂 Would love your thoughts on this, and whether we need the installers to come out again to re-apply the sealant. Thank you so much for all your help!

-

Thank you @Conorand @Mr Punter, really appreciate your insights. @Conor great point about bringing the scaffolders in - we are actually planning to take part of the scaffolding down (along with tinhat), and can just take it off without the need to resemble it. for the telehandler, do you know if there are smaller ones that can be lifted / moved into the back garden? ( Which is where the blaustrade is facing). We are a terraced house with tight access to the gardens unfortunately. Do you know if any other hoisting solutions that can be easily brought into the garden by carrying? @Mr Punter, for scaffold hoist, does it work with glass? The only thing I worry is that, being at 3m long, the glass could easily bang on the scaffold and break. Thank you both!