junglejim

Members-

Posts

256 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

junglejim's Achievements

Regular Member (4/5)

5

Reputation

-

No I have PIR between studs then ybs super quilt over the top and battened in place

-

Yes good point… I was planning on lapping up under the ybs superquilt and taping together so would need to do that before adding horizontal batten presumably.

-

Yes cross section of ground floor to first floor junction

-

Thanks that’s helpful…. Another job the TF sub contractor was supposed to have done but didn’t 🙄

-

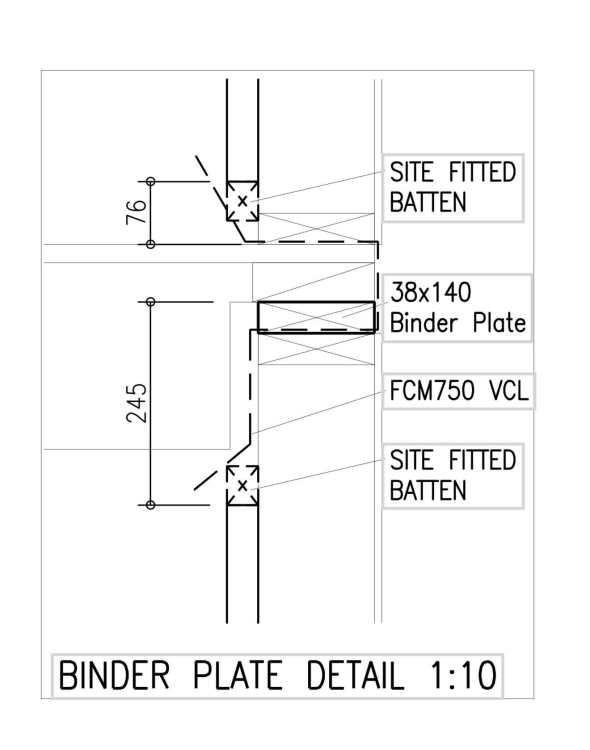

I’m looking at this detail in the drawings and noticed the ‘site fitted batten’ I can’t see this but also wonder if it’s necessary as looks horizontal which would surely block the service cavity created by the vertical battens. Given it’s in the eaves I may not need the service cavity. What’s not shown in the drawing is the ybs super quilt under the vertical battens. I’m probably missing something obvious 🙄 Sorry I haven’t got any actual photos as not on site at the moment.

-

Thanks. Would you suggest using both or can the bend supports double up as protection?

-

Looking at where the ufh comes through the screed to the manifold. Any tips on protecting? I’ve seen these used; https://www.vpsunderfloorheating.co.uk/product/ufh-90-degree-pipe-support-bend/ but don’t know if I’m better off with some ducting and if so any suggestions? Thanks

-

Thanks. Really helpful. Can I ask why put the yellow behind the upstand when on the other edges it goes in front? I thought it was to decouple screed from insulation etc? Attached is how the other external edges are done where there isn’t a door.

-

Thanks Nick. My logic was because the bottom of the screed is pretty much level with the bottom of the frame so not particularly well thermally protected from the concrete upstand. At the usual wall edges I have a 30mm pir upstand so seems to make sense to extend continue that in front of doors but given its a threshold figured it needs to be load bearing as pir would likely damage. My understanding was that screed needs to go up to the yellow edge strip hence putting that inside the grey foam. Perhaps an alternative is to use pir upstand as per external wall edges but trimmed so that screed can still go over the top but at half depth (3cm) but I’d worry this might be too thin and vulnerable to cracking.

-

Not sure the best way to approach this so advice appreciated. option A: The standard approach as per guidance from screed company is to put the foam edge strip on the door edge and screed right up to it. As per picture A. In my mind that’s potentially a cold bridge point so… option B: I was thinking about putting structural foam perimeter (grey) along the door edge and then the foam strip (photo B) the down side is that the slab will finish inside of the structural foam so the foam won’t have any compression from the slab and the flooring will overlap it. Potentially it’s not very tight and may need trimming down which will be tricky in situ but gives the edge of the slab extra insulation Any advice appreciated

-

Sounds like good logic… but Ufh is only ground floor and fed by the ashp so my understanding was that the ashp would be doing the pumping without need for additional pumps at the manifold. Are there other complaints that will cause significant noise? It’s a timber stud wall so will add acoustic insulation too.

-

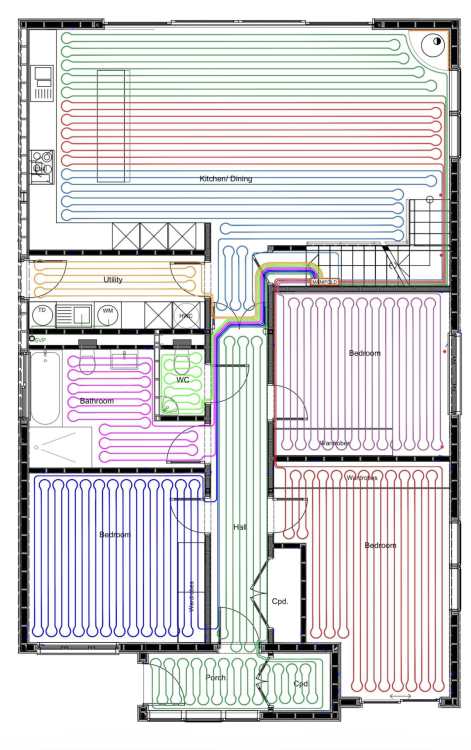

@Nickfromwales @BotusBuild @ProDavethanks for the comments really appreciate that and a few things for me to think about. CC are 150mm Manifold: is under stairs. Curious why not there and if you have any other suggestions? Also interested in advantage of going through doorways instead of through stud? Bearing in mind ufh pipe level is above the sole plate here. i can see the logic of removing or reducing the hall loop but presumably that would give me an area with inconsistent temperature/control as essentially following the heat call from the rooms. Given its low temperatures run off ashp this may not be a problem. Just seen pro Dave’s comment… makes sense. re the wood burner… slight bone of contention between me and my wife! But… will be externally fed and aiming for something with good heat retention to provide slow release heat. glad I asked the question as would have likely blindly followed the plan. I’ll go back on Monday with some questions.

-

Week 15 - UFH, screed, and render base coat

junglejim commented on Benpointer's blog entry in Contemporary build in north Dorset

Just curious how you sealed penetrations where ufh went through the stud… presumably run through a sleeve and then expanding foam? -

I’m getting close to being ready to install ufh. A local company has completed a design but I’m wondering whether I should go back and request a spiral layout? The ufh will be run off ashp, the screed is liquid (ecoscreed) and build is timber frame and aiming for good airtightness etc. i could be overthinking so looking for advice before going back to the company on Monday. Thanks

-

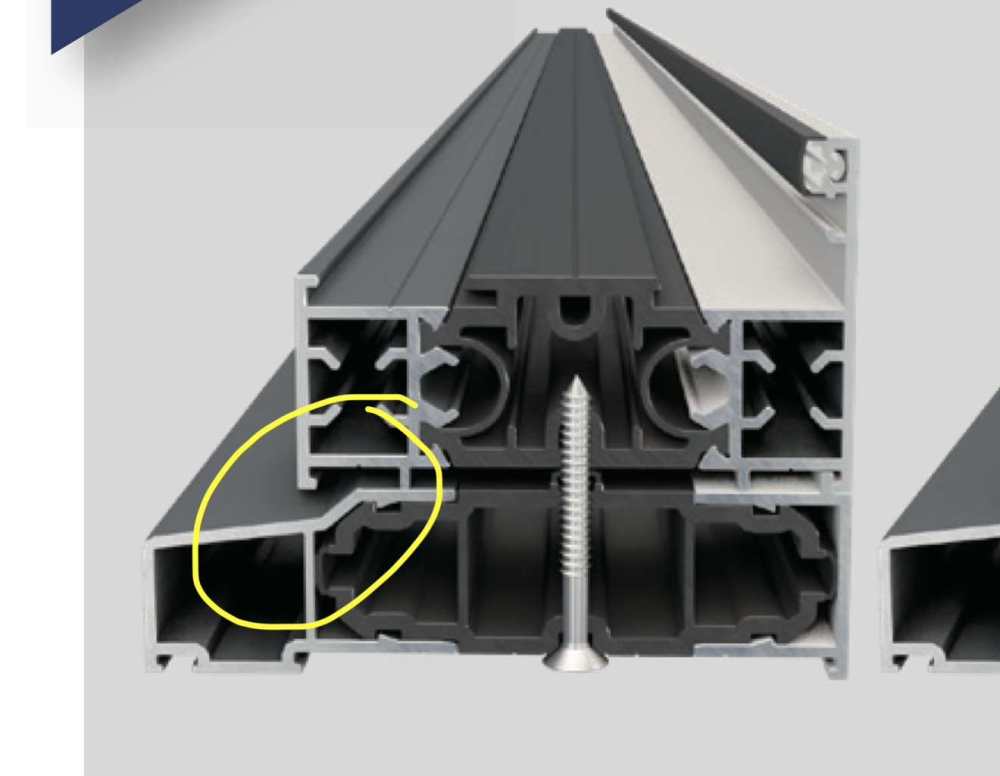

Thank you that’s helpful. Are you pointing to the groove in the window frame? One theory I have is that it’s getting in through the joint between frame and cill as circles in attached. Adding sealant where you suggest could be a solution.