wertert

Members-

Posts

31 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

wertert's Achievements

Member (3/5)

4

Reputation

-

Retaining walls required before garage foundation

wertert replied to wertert's topic in General Structural Issues

Hi All It's been a while! Got the retaining walls all built but had some issues with building control which are now sorted. The final concrete pour for the floor slab is happening next week then I can start on the walls. We have decided to go with a cavity wall design for the garage with the retaining wall above making up the outer skin. We will have a 100mm cavity and 4 inch blocks on the inside with ties every 450 centers ( screw in ) I have a question about DPC for the inner skin. I was thinking to just put some standard 4" DPC on top of the first course but wondering if there something better I should consider ? Can't see a caviity tray working here as any liquid has nowhere to go. This shows the inner block wall, cavity and retaining wall, left to right. It's all built off approx the same level slab. The building inspector has said he's not expecting a DPC in the retaining wall element. Thanks all - any ideas ? -

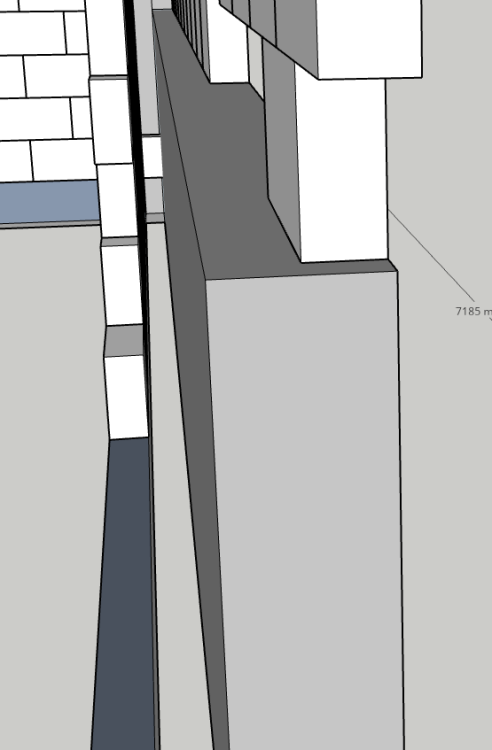

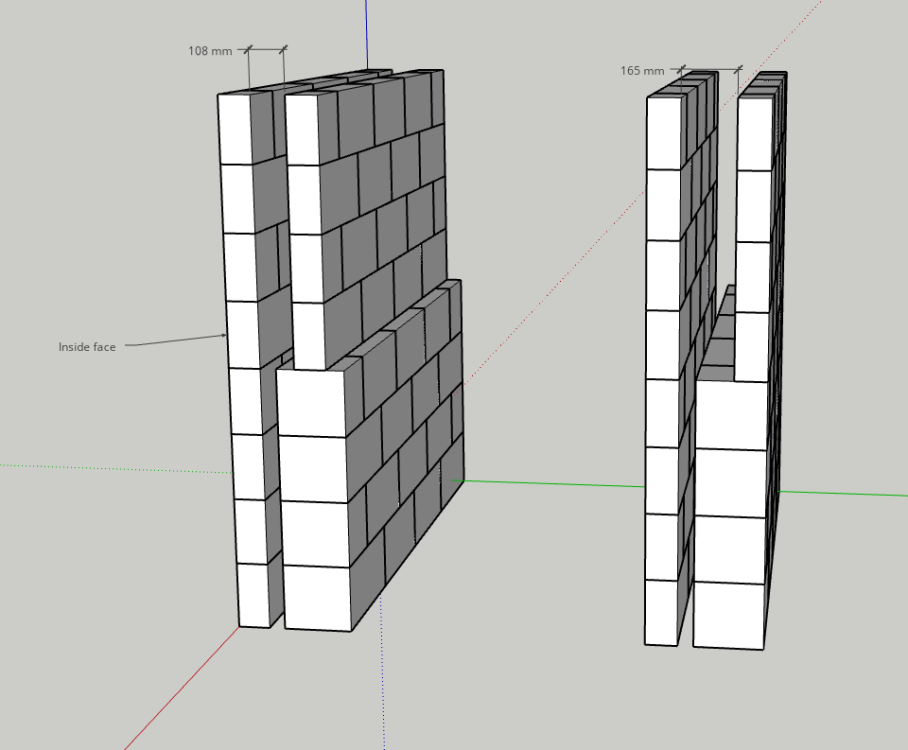

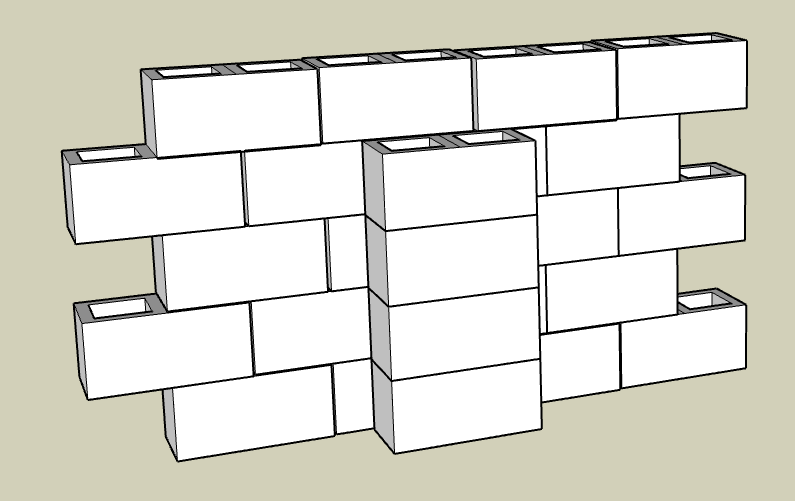

Hi All I'd like to raise a question which concerns the design of these walls once the hollow blocks are in/filled. You may have read further back that I intend to go with cavity walls with the hollows forming the outer skin. The idea is I will switch to traditional concrete blocks after 5 or 6 courses of hollows. Two options as far as I can see. Do i build the external block wall on the center line of the hollows or flush with the edge ? I prefer the right hand / flush option as we don't get a step but my concern is the wall isn't balanced ie The center of gravity is over to the right. Would this cause a problem ? The wall will be a gable end at 5.5m at the highest point and about 7m long. That's alot of weight off center if you see what I mean. Wall skins will be tied together - probably 450v / 450h. Obviously the flush design will need longer ties. Thanks All

-

Next we had the concrete. RC35 which I overordered by quite alot ! Now working on the hollow block wall Hope to crack on this weekend.

-

Hi All Hope all is well. Thought I'd put up some progress pics. We had all that rain so my trench ended up as a bit of a mess. Mesh was sinking into the soft bottom. I ended up scraping out the soft stuff and dumping in a few inches of scalpings which I whacked to give a firm base then started again. BTW - laser level. Best thing I've bought recently.

-

Hi Markc - good point. I will cut the ends off where the mesh is closer than 40-50mm to the side of the trench. 40-50mm should be good cover. Planning to make up chairs like these to support the top deck of mesh. Will need approx 2.5m of 8mm rebar per chair. Shouldn't be too hard to bend.

-

Hi All Few progress pics. Laying the bottom layer of 10mm mesh at the moment on 50mm stands. I'm planning to make up 40cm high chairs with 8mm rebar ( or 6mm ? ) to support the top layer of mesh. Progress is slow because it keeps raining and i'm trying to keep the trench as dry as possible. Ground was rock hard when it was dug out but the base of the trench is slightly soft where the rain had got in. Anything to worry about ? Maybe a few inches of type1 or plastic sheeting would have been a good idea in retrospect. Trench is a bit messy due to the number large rocks which came out. I quite want to put in some formwork for the top edge but probably not required 😉 I saw this permanent formwork being used on another site and was very impressed; https://cordek.com/products/corgrid#:~:text=Corgrid permanent formwork panels consists,ensure quick and simple installation. https://www.maxfrank.com/uk-en/products/formwork-technologies/01-permanent-formwork-pecafil/ Anyone familiar with it ? I'll probably order the concrete delivery for later in the week. Weather permitting.

-

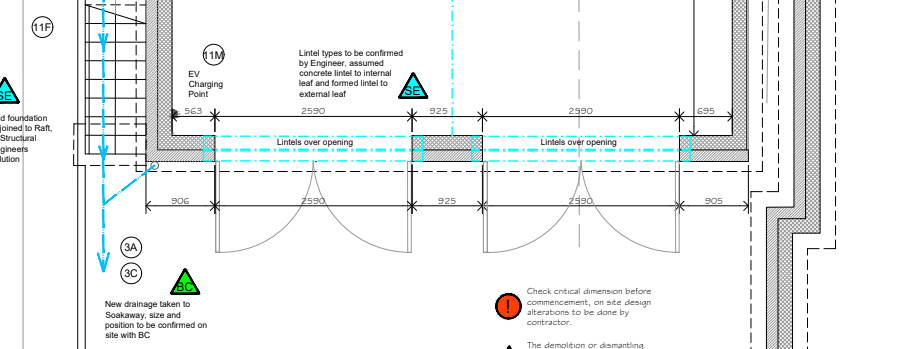

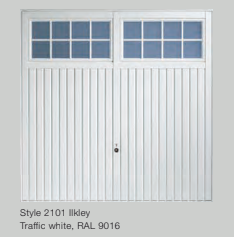

Hi AliG. Apologies - those are the old sizes from the planning application. I should have blanked the numbers out. We're now planning a pair of 8 ft wide / off the shelf doors 2# Hormann 8’0” x 7’0” framed retractables in Ilkley designs with white powder-coat finishes and standard plastic handles: 8ft sound ok ? openings will be 2590mm block to block. Doors will be up an over retractable. I also saw an example where you buy an open frame and add you own woodwork etc. Could be an option. Thanks for pointing that out.

-

Hi Gus Thanks for your detailed reply. Does the width of the cavity have a factor on the strength of a cavity wall overall ? ie 30mm / 50mm / 100mm or will it always be 2/3 ? The SE has advised that the collar jointed wall is required for wind lateral stability of the rear wall, not for load bearing. I think one problem is they never visited site. I have explained that area is sheltered and the rear wall is ~1m from the boundary wall and neighbours extension. I do not see wind being a factor here. I understand they need to design to certain standards. Ariel pic below shows outline of proposed garage with rear wall in red. Neighbours garage/extension has roof window. ( they didn't use a collar jointed wall! ) We already have the bath stone blocks that will become the outer skin of 2 of the walls. They are 6 inch thick and either 12 or 14 inches high. There is no practical way i'm going to get the courses to line up 😉 You can see the stone on pallets above. Will probably have to use the screw in stainless ties.

-

Hey George - Thanks for your input. What do you think of my last post from today ? I'm proposing to forget the laying flat idea from a few weeks back and build off the hollow blocks with traditional concrete blocks laid upright ie maximum strength as you mention above. This would then form the outer skin of a traditional cavity wall.

-

Hi All Picking up this thread again. I'm looking into redesigning the garage to include a lot of suggestions above, including traditional cavity walls. I have a question around using the existing hollow block walls as the outer skin. Not the best picture but gives you an idea of the existing hollow block wall 6 courses, Reinforced with 12mm bars, Filled with concrete etc. Hollow block wall is technically retaining but the ground is very solid and I would say minimal side load on the wall. Could I continue this wall up in normal concrete blocks ( another 6/7 courses ) ? This would then become the outer skin of a cavity wall ? ie we would build the inner skin in front of what you're seeing above and tie to the hollows. We would use screw ties into the hollow blocks and traditional ties normal block to normal block. 50mm cavity. Attic trusses would then sit on the inner skin/roof plate. We would expect to see a step in the block work where we change from the hollows to the normal blocks but other than that I can't see a problem with it. Planning to render the outside and possibly dry line inside. Great to hear the forum's thoughts on this.

-

Retaining walls required before garage foundation

wertert replied to wertert's topic in General Structural Issues

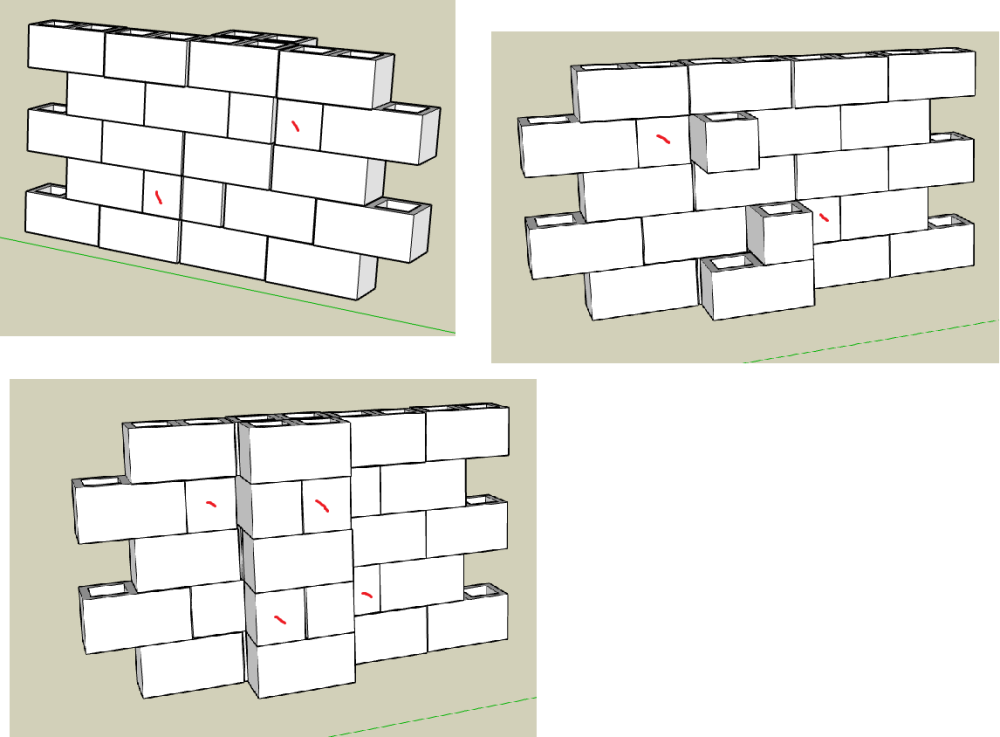

Hi All and Happy Friday. Through i'd drop a picture of the wall progress. Working on the 3rd section. 1 more planned after this so should start that this weekend. Pleased with the overall progress but my cement mixer just died. Drum bearing. I think phasing the build into 4 sections has added alot of extra time but I still think it was the right thing to do given the potential downside if the ground moved at all. Thinking slightly ahead to the next wall i don't need to worry about sections etc. i'm trying to think of a block laying pattern to give me piers every 1.5/2 meters with minimal cuts etc. Best I can come up with so far is below. Half blocks marked with red. View from the front and 2 views from the rear showing a partial pier and full. Trying to minimise any longer vertical joins, best I can do is 3 courses. How do the pros do this type of thing ? Alternative is simply build a flat wall with piers added separately with no cross/bonding blocks ie -

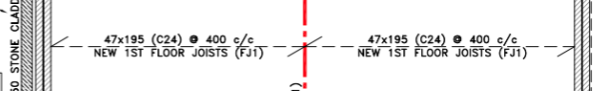

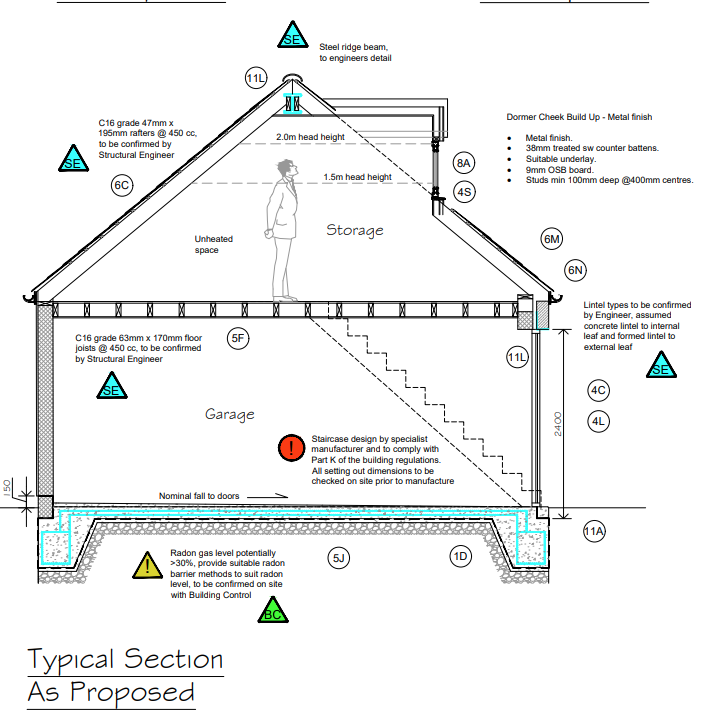

Hey ETC. Raft is down to local conditions. Last garage suffered due to subsidence and the site is slightly sloping. We also have/had trees around and although they've been cut down (4 years) we are suspicion of the ground conditions. Raft was recommended as the safest choice. Our neighbours did the same when they built their extension. So do you mean build dual skin cavity blockwork wall and inject insulation later on if we decide or insulate on the inside ? What sort of cavity would you go for ? I actually think that would be easier to build than the weird 210mm design we currently have. Not sure I understand the attic truss option ? I did ask about this during design. COuld we have trusses and retain the first floor height or would it be higher ? SE / Architect said we needed the steel due to the spans. Roof is ~8m long. So not required with trusses. ? The 2 sizes are because the SE superseded the architect recommendations. so we are looking at So we went from 170mm to 195mm. Agree with you on the cop out of the stairs. They were useless on these. I'm no builder and I have concerns over aspects of the design. Hoping to find some answers in this forum so thanks again for your input. At this point I'm thinking I need to get the whole design peer reviewed. Any recommendations ? New set of drawings. Haven't gone through building regs as yet.

-

Hey canski, I'm actually planning to do away with the stepped raft and just square it off. ( Subject to SE approval of course ).

-

The wife said they looked sweet ! 😉 On your earlier point The architect had originally designed the walls to be in 140mm concrete blocks. Single skin. I liked the idea as i'm building it myself and this seemed straight forward. Once we got the SE involved for building regs they stated that 140mm wasn't strong enough etc etc and came up with the 210 dual skin. I think this will be tricky to build, I imagine you'd have to build one skin and let it set before laying the second and filling the mortar gap as you go, will make the wall ties interesting as walls are offset. Grateful to hear any other ideas on how to tackle this. I need to understand why the 210 dual skin is better/stronger etc than laying standard blocks on their bellies. What is the advantage ? Any SE's out there who have a idea ?

-

Hi Bassanclan. Thanks for that. Now I'm worried ! What would you expect to see on a building like this ? We have 2m head height in the center. Only really planning to use this for storage so may not even insulate it.