SanMan

Members-

Posts

26 -

Joined

-

Last visited

Everything posted by SanMan

-

A few years ago, we had new windows fitted and in places were left with slightly large gaps between the frames and reveals. We don’t want to use plastic trims or sealant.We also don’t want to simply plaster over the gaps because then it looks like there is a small section of wall next to the window before it does a right turn into the reveal. What is the best way to fix this without replastering the entire wall? Is there any way of attaching a new corner bead at the front of the reveal (by recessing it into the existing plaster or overlaying/feathering it in), fitting a piece of plasterboard into the reveal and then finishing it with plaster? Or are there other options? Thank you.

-

Thank you for your replies. 😊

-

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Thank you. We have a very expensive prime engineered oak floor, so I am very reluctant to raise the temp above the manufacturer’s recommendation - in fact, when the probe triggers a switch off at 27, the residual heat often takes a while to reduce and the probe reads as high as 28 - so increasing the cut off would really take it nearer 29 or beyond - not a risk I am willing to take. The system performed fine all last winter. I think there must be sludge in the loops or air. I noticed last night that the pressure gauge is slightly down on target and the “shot glasses” on the flow meters have black stuff in them, making them hard to read. No idea how to clear that without my plumber who is not getting back to me. Thank you for your help. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

How can you tell? Cold spots? It is much harder to feel for cold spots on a floor (compared to a radiator). And how do I bleed? Open the bleed valves on the manifold? Thank you. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

-

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Yes. I read one article once where they said cut it 5 mm LARGER to ensure a good fit. 🤔 The problem is the joists are tapered/uneven in themselves and using foam when working in a ceiling against gravity is no fun. So I thought 100 mm Rocksilk will solve s multitude of fitting issues and that can easily be oversized and will still stay in. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

And how do you feel about 100 mm Rocksilk? Much easier to fit than Celotex. And would it need to be foil faced like the Celotex? Thank you. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Yes. I was wondering if that is ok. No need for air gap? I guess that would defeat the object, having read your other reply. Thank you. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

That is really helpful. Thank you for your advice. 😊 -

Hi I want to insulate an internal floor void. I have to do this from underneath as the floor above is finished plus the room below needs a new ceiling. The joist centres vary from 290 to 350 mm, so I gather Celotex would be a nightmare, also because the joists are frequently tapered. The joists are 200 mm tall. So I was going to use 100 mm Rocksilk slabs. My questions: 1. Should I opt for foil faced? What is the benefit? Which way should the foil point - up towards floor or down towards ceiling? The main aim of the exercise is to reduce downward heat loss from the UFH floor above. 2. Do I need an air gap between the insulation and the floor above? Or is the 100 mm void left between slab and ceiling below sufficient, especially because the ceiling will have downlights. 3. What is the best way to secure Rocksilk slabs from underneath, to stop displacement, sagging and ensure good contact with the floor above? Thank you.

-

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Good idea. The ceiling underneath is a mess and has to come down anyway. I wonder if I might just take one sheet down and insert an insulation slab, to see what that does to the surface temp feel of the floor. PIR is a nightmare between our joists because of the age of the house. No two joist bays are the same and as the timber has expanded and contracted over time, the joists are a tiny bit “wriggly” (not 100% flat/straight) - so I was going to use 100 mm Rocksilk slabs as they are more accommodating if cut slightly too large. You know what fun it is to try to cut PIR exactly right! Thank you. 😊 -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

-

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

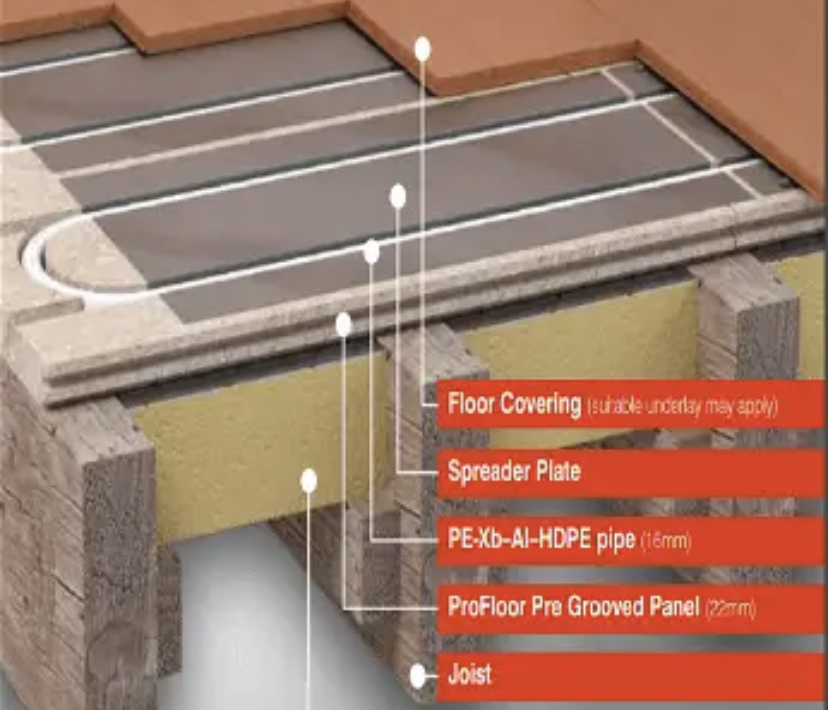

Thank you for the reply. The layers are actually like this (starting from the bottom up - some insulation, routered chipboard, spreader plates, thin Tuplex underlay, Kahrs oak engineered flooring). In other words, the spreader plates are on top of/bedded into the routered chipboard, not the other way round. I attach a photo. The thing I am missing from that photo is a slab of insulation. My question is will adding insulation make much difference, given there is a heated room below. The floor joists are 200 mm tall, so the void is quite spacious. There is some insulation there, but only loose full fibreglass. And if I add insulation slabs, should they be pushed right up against the chipboard. And should they be foil face up? Thank you. 😊 -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Thank you for your reply. It is my daughter’s room, so in the school holidays especially she spends long periods in there. It is then used more like a living room and as you know they are set slightly warmer than bedrooms. Also, 18 is the point it gets to and then the floor protection probe switches the heating off until the boards have cooled enough. It switches back once the temperature has dropped to nearer 17.5 - so in practice the room is rarely at 18 for all that long, but just under. My question is really: is my concern of heat loss into the ceiling void below valid? Or is it not worth upgrading the insulation and directing the heat upward as the room below is heated? Thanks. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Thanks. Flow temperature as in temperature selection at mixing valve? Doesn’t this just cause the limiting function to kick in sooner? Limit is set at 27 degrees. The mixing valve is presently set to 50 degrees, but I understand it can be increased to up to 55 for suspended timber floors, provided that you always have a working floor temp probe to protect the floor. I must admit it sounds like this spreader plate contact problem is an inherent drawback of this type of system because truly, I cannot see what could have been done differently. Thank you so much. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Have replied above. Thanks. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Have replied above. Thanks. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Thank you @Nickfromwales. Yes, I saw it installed. The floor is Kahrs engineered floating on the spreader plates. Did not look like lack of contact - the fitter even screwed all the spreader plates down as they would otherwise have been a bit springy and that would have reduced contact. ProFloor don’t ask for this, but another well known manufacturer of the routered board/spreader plate system does. How do you overcome poor contact? ProFloor is sold as suitable for taking a floating engineered wood floor. Thank you. -

First Floor UFH - Role of Subfloor Insulation

SanMan replied to SanMan's topic in Underfloor Heating

Thank you for your reply @Olf. The kitchen is quite a warm room with its own heating - it definitely doesn’t need help from above 😇 (except on the energy price front maybe! 😂). Floor surface temperature limit is 27. I can increase the mixing valve to 55 but I find a hotter flow might just trigger switch off by the floor limit function sooner - or am I wrong there? Can you help with this: As the joists are a not dead straight, I would like to use Rocksilk slabs rather than Celotex as the slabs are more forgiving if cut slightly too big. Is it worth going for foil faced slabs? And if so, should the foil side be nearest to the floor deck? And finally (sorry) - Do I need an air gap between the underside of the floor deck and the slabs or is a close contact fit best? The total joist height in the floor void is 200 mm, so I was thinking add 100 mm slabs, secure from underneath and leave 100 mm space between slab and kitchen ceiling plasterboard to ventilate the floor void. Thank you so much. -

I have upstairs bedroom with UFH and it is struggling in this weather. Max room temp 18 degrees. The set up is: - suspended timber floor - ProFloor routered boards with spreader plates - Kahrs Tuplex underlay (recommended for UFH), then Kahrs engineered oak - subfloor void is insulated with loose fibreglass, avoiding downlights for room below, so somewhat gappy - room below is heated kitchen Yesterday, I removed a downlight and put my hand in the void. It felt very toasty. I could touch the underside of the ProFloor boards and these felt quite warm. So my suspicion is that the insulation is insufficient and I am losing a lot of heat downwards into the kitchen ceiling rather than into the room. Other info: - room has insulated cavity walls and new uPVC windows - bedroom ceiling void is insulated with 120 mm Celotex (cold loft above) The system settings are: - mixing valve set to 50 degrees - flow rate 1.4l/min - pump speed 3 - only circuit on manifold (70 m length pipe around the floor area of the room) - manifold only 3 m away from room, approximately 8 m between manifold and condensing gas boiler - all pipes to/from manifold lagged I was told by Building Control that insulation in internal floors between ground and first is not necessary, but as we are talking underfloor heating, I did it anyway. Well, I don’t think it is enough and I think it should have had 100mm rocksilk slabs or similar pushed right up against the underside of the ProFloor boards, to ensure heat travels upwards into the room and not downwards into the floor void. Yes, heat rises, but I think here it goes both ways. Thankfully, the ceiling below is due to come down and be reboarded/skimmed anyway as the downlights are all in the wrong place - so I can add the insulation from underneath. Can I have your views on this before commencing these works? Thank you.

-

Thank you @Radian. Yes, I wonder if this is it. A fitting error that cannot be rectified? Is the unit possibly too big for the reveal? Anything I can do?

-

-

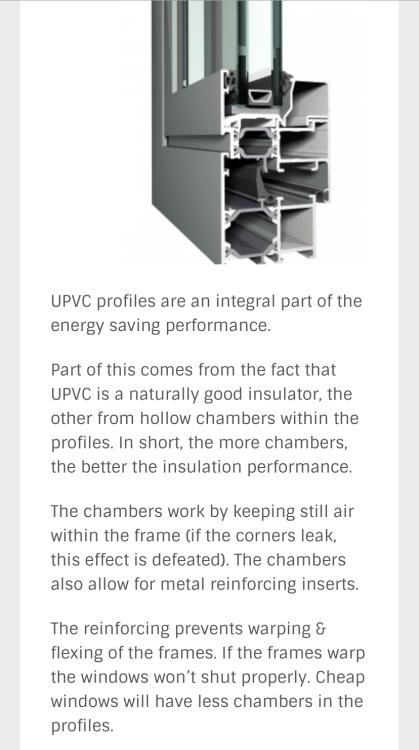

There is no insulation in the uPVC frame. The thermal qualities rely on the hollow plastic channels in the frame.

-

Thank you. Yes, they used cavity closers. I watched them do it, but there are lots of windows at our house and they had 4 people working, so I did not see every single step. When they took the old windows out, they disturbed plaster and the edge of the brickwork. I wonder if there are ragged edges. I have a boroscope….I wonder if it is worth drilling a small jolt into the reveal to have a look. Also, why would the actual white frame be so cold? Thank you.

-

We had new Rehau uPVC windows installed earlier this year. Now that the cold weather is here, I have noticed that some of them feel noticeable cold and draughty around the reveal, not the glass or rubber gaskets themselves. It could also be coming from the outer uPVC frame, I am not sure. Please see attached photo. It almost seems like there is a hollow around the window. Only some windows are affected. How is this possible and can this be recitified, for example by drilling a hole into the plaster of the window reveal and injecting foam? Thanks.