Angelheart

Members-

Posts

18 -

Joined

-

Last visited

Everything posted by Angelheart

-

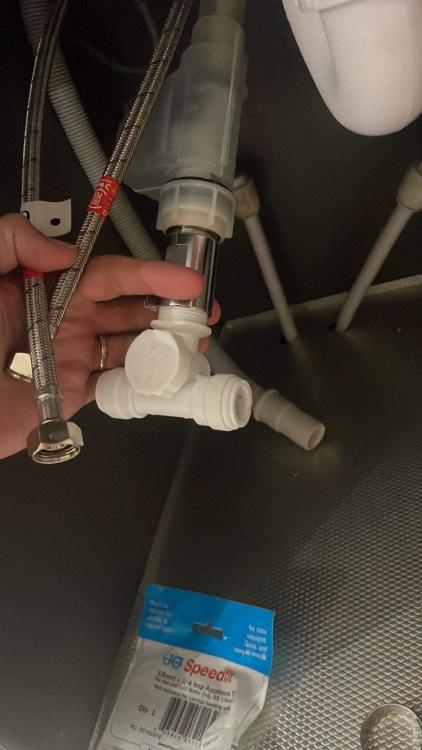

Long story short, when my extension was sorted out, the plumber did not put an isolator on the hot supply. That loop feeds my en-suite and kitchen. When my heating was sorted, that was connected but there was a leak so my heating guy took off the connector. 22mm copper to 15mm poly. Now I want to add in the isolator and reduce. I have the parts now to do this but the previous connector and reducer is smaller than my isolator and reducer. Therefore I will have to trim one or other of the pipes back. This is a bit tricky as it’s all installed there and I’m only used to dealing with connecting things as I go and having free pipes. So my questions are, is there an easy way to gauge the correct gap I need to leave between the pipes and also, what would be the best method of connecting this all? Re my pics: Spigot reducer thing is not pushed into the isolator as I thought it may be better to install in stages as that is an easier one to push in last than the actual pipe. Pic of what I’m dealing with, 22mm copper from below, 15mm poly up top. Thanks in advance for any advice you can offer.

-

This is not a bad shout actually @Temp. I have found some that would work but it’s a box of 50, will dig around and see if I can buy them singularly anywhere.

-

-

I am having galvanised guttering and down pipes. I have cladding on the top half and the bottom half is rendered. This means the downpipe is further away from the wall than the top half. I need some sort of spacers behind the downpipe brackets. I have measured and it is approx 2”. Ideally I would like it to match in with the material of the downpipe which is steel. I’ve had a look and can’t really find anything suitable. Maybe they have another name I can look for or perhaps there is an alternative I can use. I prob only need 8 spacers altogether. Thanks in advance.

-

-

Ok perhaps I should order one and give it a go. I’ll investigate this further. Thanks for the suggestion.

-

Ok I’ve got those connected now MJ and the connector will go straight into the top of my T for the dishwasher. Thanks for that info! So just a couple more questions so I can get this straight in my head… am I better just to run one piece of copper up from underneath the unit to each feed on the sink. I assume that I can put copper into the pushfit shown there? If so it’s quite simple from here forward. And lastly, I’m understanding the diagram a bit better for that triangle plastic piece. All the diagrams show the tap going through the sink which mine doesn’t so I’m still unclear as to whether it is necessary or not. Do you think I should contact V&B to clarify as the instruction booklet is as clear as mud 🤣

-

I cannot picture in my head exactly what you mean.

-

I already have these, so is it better to just buy those bushes that I posted above or is your link the better option please?

-

Am I right in thinking that I need a couple of these? I think this will solve my first issue. Had a bit of a drama earlier involving my daughter and a water spillage and ended up taking the kickboards off, discovered which of my inlets was hot and which was cold so that was a win as they were not marked where it was visible 🙈 Would I be better to tidy these up below and come out of the elbow in copper straight into the cupboard above which would save me using the straight compression couplers that I purchased earlier and have less connections going on? I am assuming that is possible as I have seen copper used in the plastic fittings?

-

Thanks for your response MJ, yes sorry my bad, it shows as blue in the leaflet but the part is actually white. Mine is going straight into the worktop as I don’t have the arrangement shown in the diagram and I have quartz which is 20mm thick therefore is your opinion that I do or do not need to use it? Yes I’ve considered both of these options but feel that the addition of this sleeve on the waste pipe will prevent me from doing that due to the space needed, the Hep one is def too long, the McAlpine is a bit shorter. I will take a look for the size coupler that you mentioned, they don’t seem to do this size in mainstream places like screwfix that I can see.

-

Thanks Mark, they sent me a report back with the details on. Do you still think I should send off my own? I’m sure it can be removed in whole pieces and they are just making extra work and expense. I think they said if it was unlicensed then they would have removed it themselves but as it is licensed then they won’t.

-

-

-

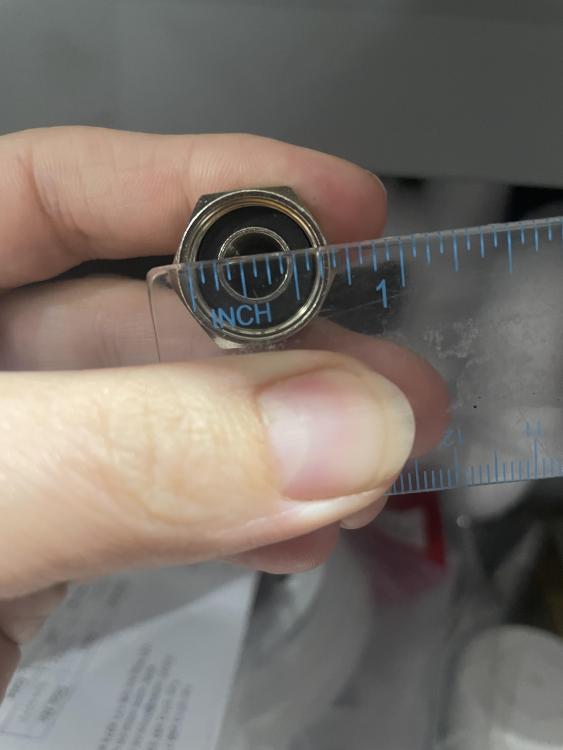

Firstly I have a V&B kitchen tap. I need to use couplers to connect to 15mm pipe. I have taken a pic of the tails from the sink tap, does anyone know what size this would be as I’ve already been to Screwfix twice and the 15mm x 1/2 are too big it seems? Also is it the best idea to pipe under the sink in copper as much as possible? I have poly coming in but need to link up to my dishwasher and tap. I was planning to use a 15mm straight compression fitting on the poly with the pipe insert. I have a t with isolator to branch off to the dishwasher. Does anyone know the purpose of the white triangle piece and what that is telling me? Finally, I have two drawers under my sink unit. The lower drawer is fouling on the trap. Seems a poor design of the Ideal Standard drawer unit really. I’ve looked into using the McAlpine non return valve but realised there is some sort of collar on the waste pipe that was not there before so I think this will be in the way of the nrv as they are quite long and I’m limited on depth available. I’ve purchased a shallower trap but this will still mean cutting the drawer, albeit a bit less. I have about 2” from the underside of the pipe to the drawer edge. Any advice much appreciated.

-

Long story short… I have asked a National company to replace my fascias and soffits. They sent out surveyor and he took a piece of material away to test and turns out my very small soffit is chrysotile cement board type. So they are already charging an extortionate amount so I enquired about getting it removed myself a couple of days prior to installation. They have said this is fine but they need a clean air certificate in order to proceed with the install following the removal. As this is all outside, surely it would just be measuring the cleanliness of the countryside air, I don’t get it. Can anyone shed any light on this nonsense? Many thanks