PhilC

Members-

Posts

32 -

Joined

-

Last visited

Personal Information

-

Location

South East London/Kent

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

PhilC's Achievements

Member (3/5)

4

Reputation

-

What does self build mortgage conveyancing involve

PhilC replied to PSC88's topic in Party Wall & Property Legal Issues

Hi, please could you share the name of the firm you used. -

Thanks for replys

-

I did all the planning and building control applications (had the timber frame, steels and foundation designed), so I dont have an architect already working on the project.

-

Hi All, Appreciate any recommendations for PCC / Warranty. We have planning and building control done, getting the financing together now. Thanks.

-

Hi All, Appreciate any recommendations for self-build insurance. We have planning and building control done, getting the financing together now. Thanks.

-

Trying to work through this detail myself for a timber frame new build. @Great_scot_selfbuild who did you go with for the calculations? I take it most SAP assessors are not doing the calculations themselves, I would imagine it's down to the assessor but if I can point them in the direction of an accredited junction as per 4.18 section b, then they shouldn't need to do that particular junction right?

-

Timber Frame Wall build up for extension

PhilC replied to southcoastseagull's topic in New House & Self Build Design

Not a pro as I said but PIR is not breathable so if moisture gets into the frame and you have another non-porous layer VLC/PIR internally then the moisture can't escape anywhere. -

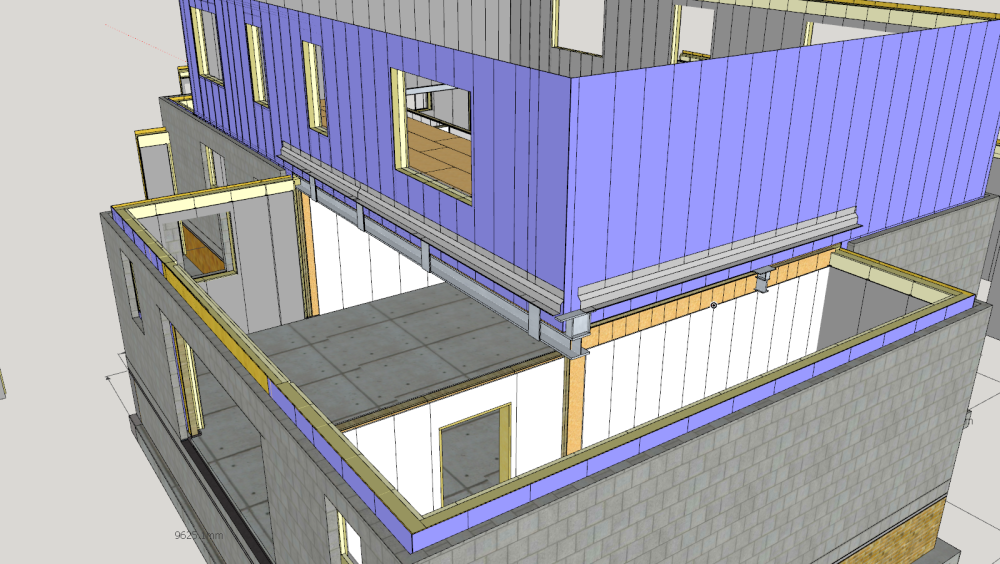

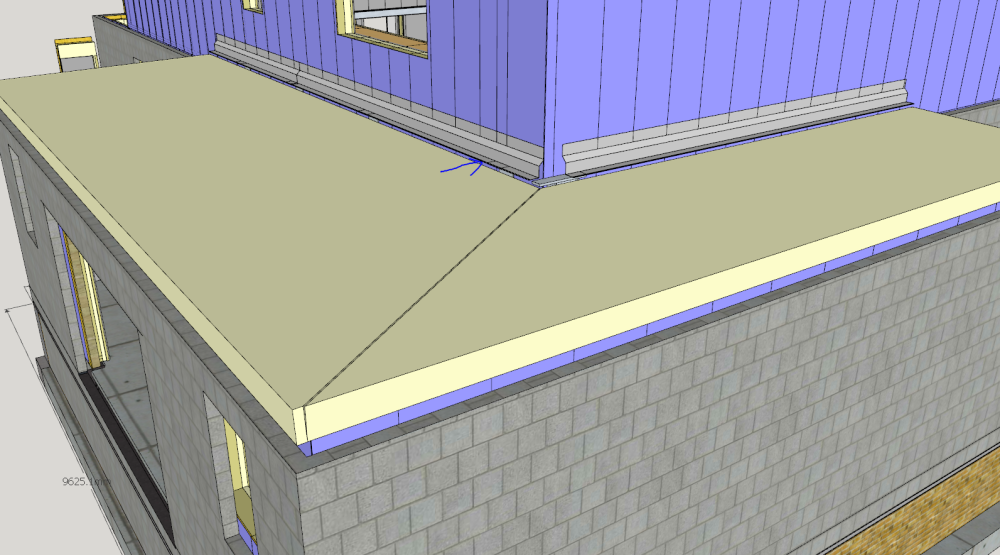

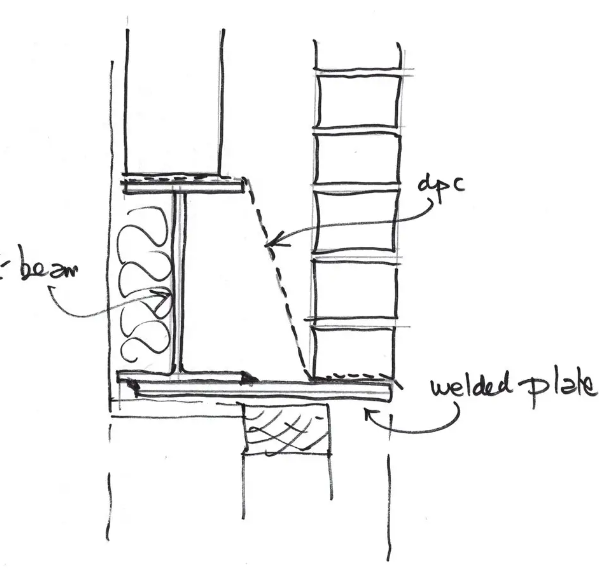

Hi Everyone, I am in a bit of a puzzle about how to detail the steelwork to support a 100mm block (rendered) wall (~2.5m height lightweight block). I could put the timber frame lintel or steel beam to carry the external block leaf lower down closer to the main beam but this creates a large thermal bridge in my mind, between the timber frame panel and the flat roof insulation. Raising the lintels up allows the PIR to come in underneath and prevent the thermal bridge. I did speak with my SE about it and in principle he thought this was ok. PIR of flat roof can come up to the frame under the masonry external leaf. Weather tightness, cavity tray etc would be above this to run out to the roof deck. The alternative is to bring the blockwork down to the steel, although this is an issue because the steel is 254mm high as are the metal web joists in the floor, so it takes the full-height plasterboard to T&G deck of the floor level so I cannot have a flat plate weld on it and as said, this seems to create a large thermal bridge even if the cavity is packed out with insulation below the cavity tray. I appreciate thoughts on this one, seems right to try to bring the flat roof insulation under and up to the frame. Render board is an option I guess but I went that route when planning our new 1st floor renovation rather than a new build, it seemed very expensive for the material and work and I think it may be difficult to match up with a rendered block ground floor. Also, I had virtually no interest in quoting for it, part of the reasoning for switching to a new build. Thanks.

-

Sketchup make 2017 free version

-

-

Thanks

-

Great stuff really helpful Liam! Hope the project is going well

-

Local authority or private?