Caversham Build

Members-

Posts

30 -

Joined

-

Last visited

Everything posted by Caversham Build

-

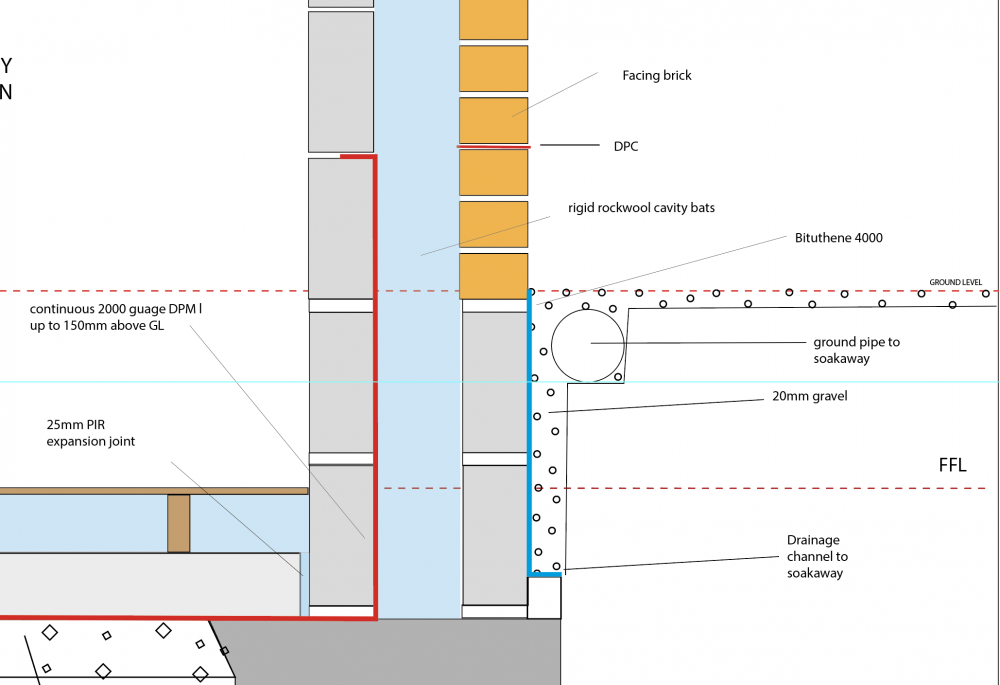

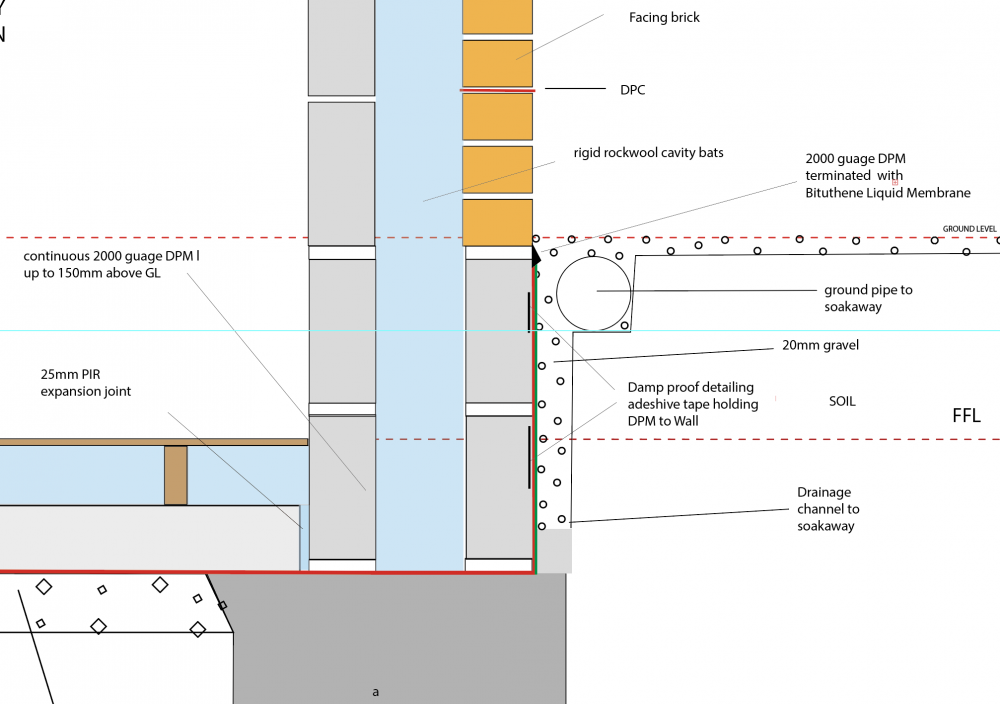

I think i am losing a sense of why i was trying to do this in the first place.🤯 I thought it was to try and stop water getting into the building in the first place in the event of very wet ground or flood - but that's tanking right? So with a DPM detail thats more standard - i'm, in general, obstructing the transference of moisture from the outside to the inside. BUT if the building gets very wet or there is a flood a more standard detail will allow me to dry things fix things out more easily? I'm so confused

-

@tonyshouse thanks for your response can i please ask: Can i use EPS for below ground level and rockwool above/ - my bricklayer who i have been trying to keep sweet as he is very good and they are in short supply told me to use Rockwool i think it makes his life easier. Floating floor - as in lose the wooden joists bridging the slab?

-

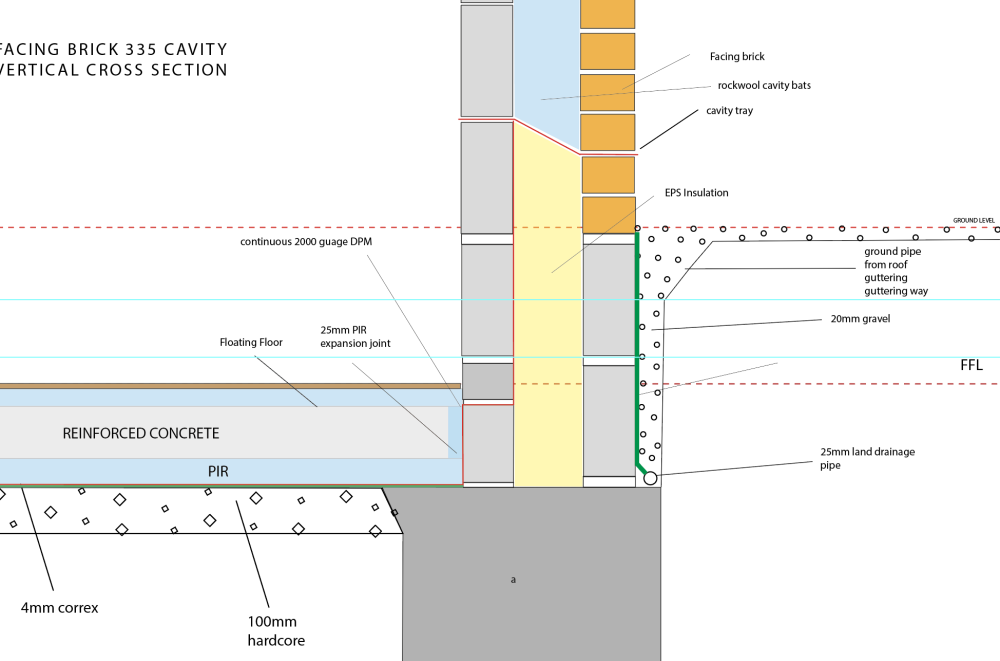

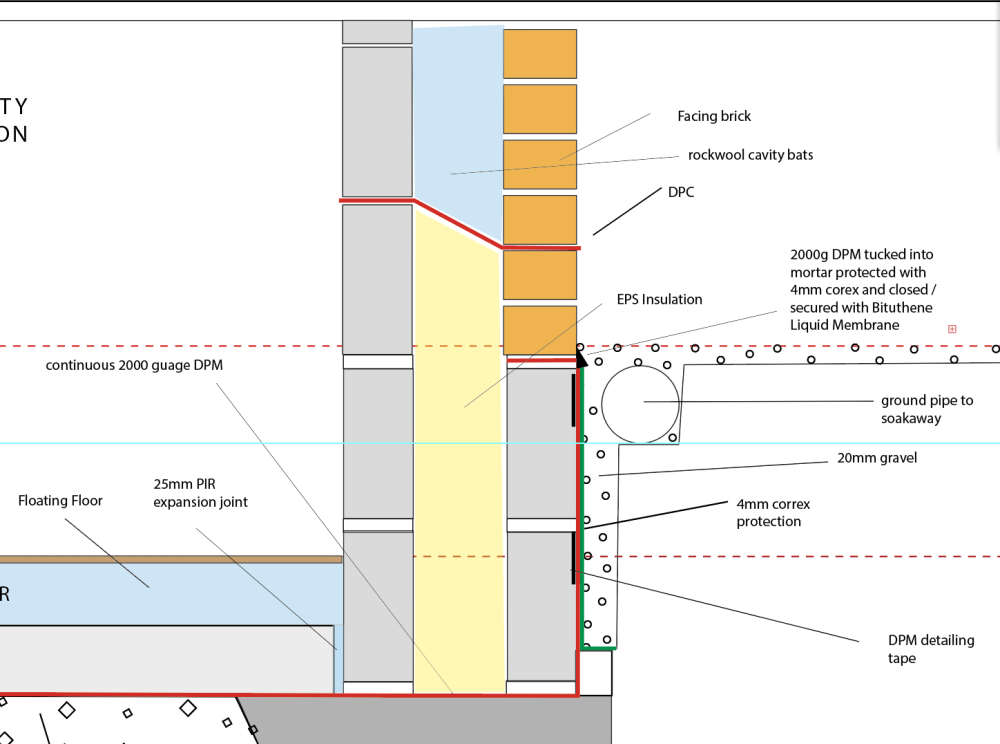

Hi all, me again, Thanks for all your help so far. I have another question I want to protect against ground water / rain water / holy water the lower 500mm of my outbuilding, as it is below GL in a quite wet area. My first detail was this : But i have come up wit this detail instead which, to me, will do a better job and much cheaper: pretty please please could you tell me if this can work / share your wisdom apart from the 'change your design so its above ground level' wisdom thank you

-

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

thanks please do point me int he direction of one, i cant seem to find any simple fixed glazing windows that have a simple thin frame like this -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

@saveasteading thanks. when you say my proposal looks solid, are you referring to my most recent 'internal frame' detail ? thank you -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

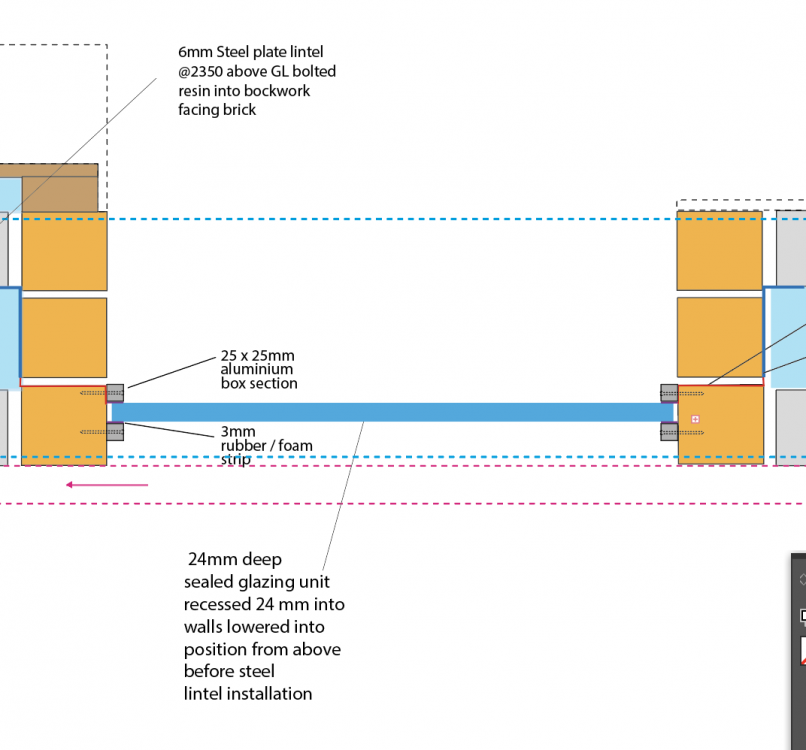

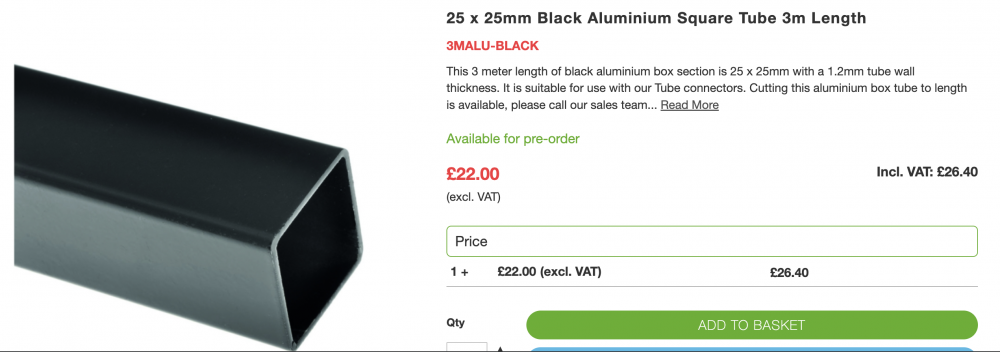

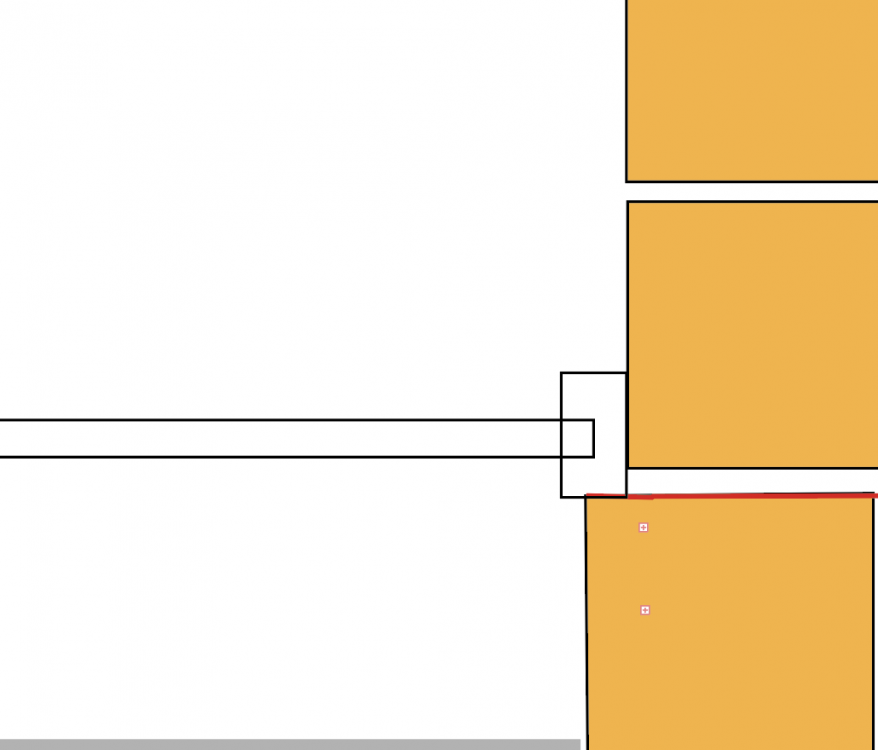

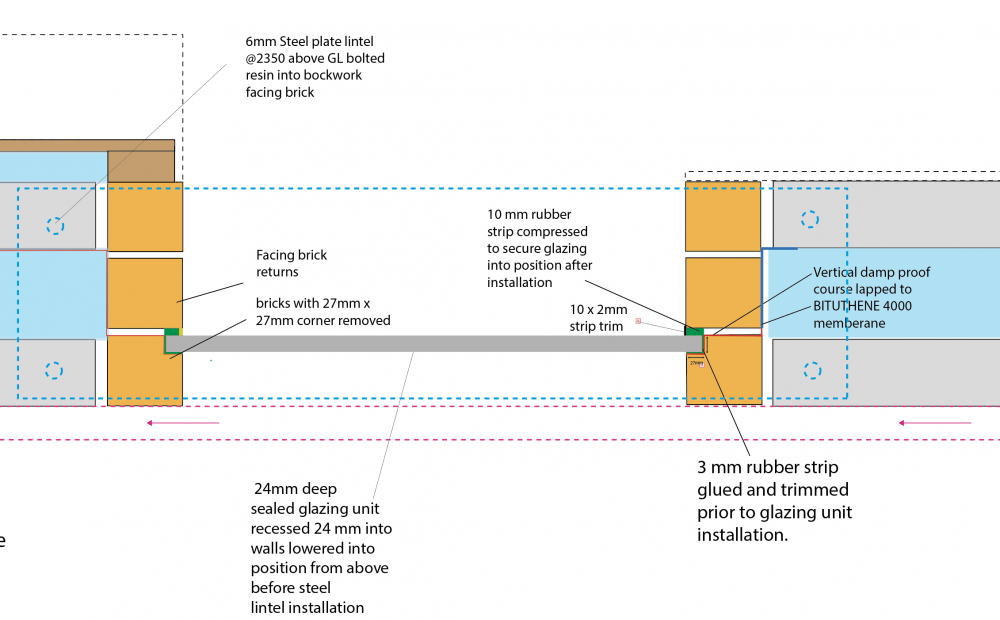

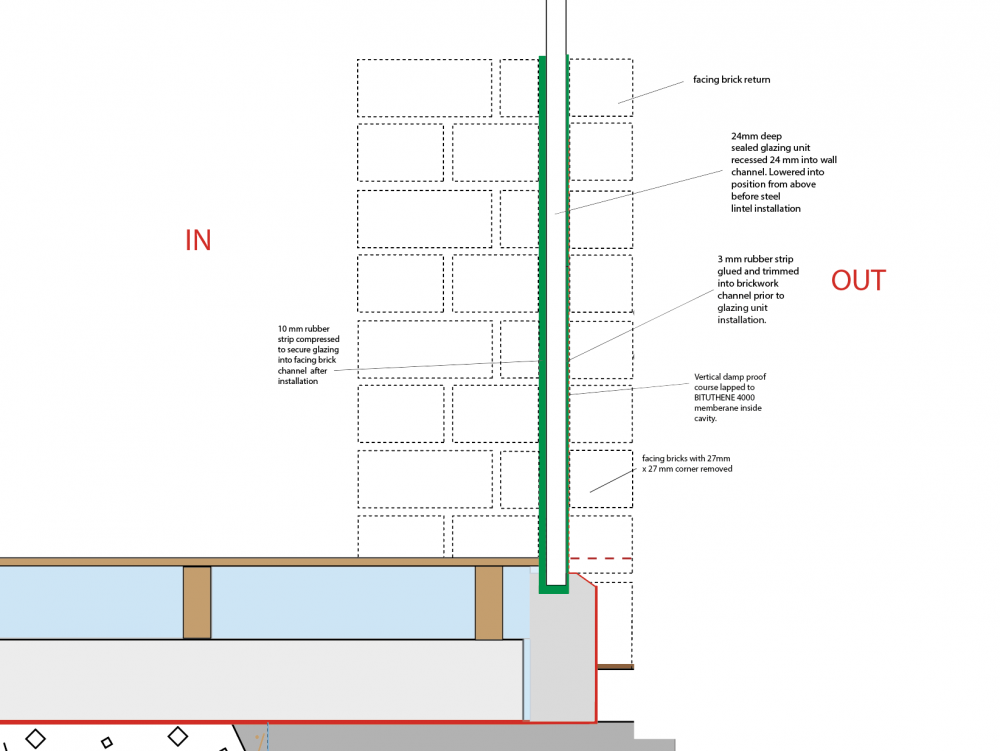

Thanks for the help / advice everyone here is my latest design, it means i would have a 25mm frame around the glass but i think the sightline on the glazing units are 12.5m anyway. Again please do tell me why this design is not possible if you can I'm still tempted to try the original design, you only live once and we'll be knee deep in world war three soon. -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

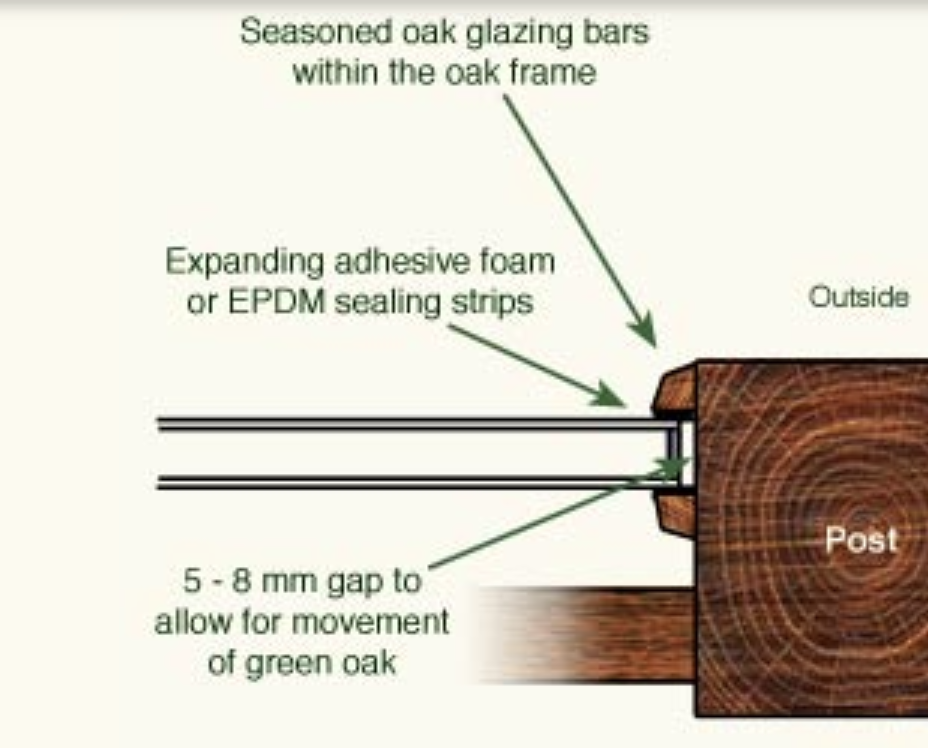

this is interesting. so in theory if i can attach glazing bars to the brickwork (flush pointed) and line them with the epdm foam on both sides inside and out as per the diagram. This will allow me to mount the glass in between the two returns. if i left my self 10 mm either side for an expansion then i could probably get away with a 20 - 300 mm profile. i would need metal glazing bars that i could screw into the wall and then finish with a strip. i guess this is essentially just thin framed glazing that i build myself right? -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

Thank you for your input Jilly Can anyone actually recommend a reasonably priced thin framed glazing unit / brand ? Everywhere i look the description is 'frameless' or 'minimal' frames or 'ultra thin frames' and the frames turn out to be minimum 60mm - i would be happy to put an internal frame on the brickwork if i could get the profile down to 30mm or less. thanks -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

Hi JohnMo thank you for taking the time to respond, Have you checked you have allowed enough room for the glass thermal expansion and any settling of building at sides, bottom and top of glazing. No i've not allowed for expansion or settling, could you give me a rough guide figure? All you sizing looks tight for easy assembly, the rubber glued to the glazing may cause hang ups when trying to insert in to block work. i was planning to glue in the 3mm rubber strip onto the brickwork channel/dpm, then once i have lowered the window in from above, push it up against the 3mm rubber strip and wedge the 10mm rubber behind it. - should i give it more space anyway? Do you need a weeping hole at bottom to prevent any water accumulation? I'm not sure. do i? do you mean in the sealed glazing unit (i'm guessing not) or somewhere else? - where would the water accumulate? squse all these amateur questions but i really am an amateur thank you -

Frameless glass windows - my design.

Caversham Build replied to Caversham Build's topic in New House & Self Build Design

Hi PeterW thanks for taking the time to respond. Are the monumental cold bridges the brick returns ? or the window wedged into the brick channel? or something else? If it's the brick work aesthetics have to come first unfortunately. If it's the glass perhaps i could use another material that insulates better instead of rubber ? In terms of replacing a potentially broken glazing unit my plan was remove the rubber, cut the pane in half, remove it, then cut a bigger channel (deeper and wider in the brickwork enough to slide in a new pane and cover with a bigger finishing strip. grind off the internal top of the sill and then place new glass in and re seal - Any idea the lifespan of sealed glazing unit? does stepping back the brick work mean not having a straight line on the return a bit like what i have drawn here attached? thank you -

Frameless glass windows - my design.

Caversham Build posted a topic in New House & Self Build Design

Hi all, i am cannot find a glazing supplier who can provide some nice looking, reasonably priced, frameless glazing. Most suppliers will not even speak to me as their minimum contract is 25000 some 30'000! I need two 800mm x 2500mm windows in between two facing brick returns. I have designed my own version of frameless glazing using sealed glazing units and rubber seals wedged into a channel in brickwork Can someone please tell me why i cannot do it this way, why is is not structurally suitable, or why it will endanger life or any other reason to not do it this way. This is a new outbuilding no more than 30sqm and built of substantially non combustible materials so not subject to building regulations. thank you for your help! -

Nothing like hanging off a bass bin at the rave.! when your whole body vibrates

-

this is probably one of the best:

-

....and if anyone thinks i am a troll / taking the michael here are 60% of my babies close to being cleaned and laid in their second home in over 120 years.

-

Hi all, I have read this forum many times whilst searching for information relating to my build and its been incredibly useful, so thanks all. I am building a room in my garden which i hope will also serve as a small art gallery. A few interesting(ish) facts about me: a) I love bricks and collect them. Particularly, wire cut, gas fired bricks, that have purple headers i guess you would call them multi stock in the trade. b) I love drawing things with straight lines. Building plans are right up my street. c) I am training to be a gardener and would like to work in horticulture one day. d) I love drum and bass and jungle and plan to build a massive sound system one day so the whole neighbour hood can enjoy it too. See you around C