Leaderboard

Popular Content

Showing content with the highest reputation on 03/02/21 in all areas

-

This is my interim plan. One of the BuildHub forum myths is that ASPHs are no more expensive to install than a gas boiler. This is based on a few forum leading lights who sourced their barebones ASPH units off eBay and installed themselves. The ordinary self builder who has not created a passiv house will have to overspec the ASHP to avoid frosting problems and the all too typical woes of an undersized ASHP which gets us to a starting price of £7k. Then those not up to speed in DIY ashp installs will encounter premium labour rates for installing exotic eco technology.4 points

-

2 points

-

Looks like the type of junction boxes associated with a burglar alarm. Maybe where PIR's have been removed because previous occupants had pets etc. Is there an alarm there now?2 points

-

Standard strainer waste https://www.screwfix.com/p/stainless-steel-strainer-waste-1-bowl-90mm/9411k That's just a cheap no name version, you can pay a bit more for a decent make like McAlpine.2 points

-

My boss says "It's always the windows that go wrong in Grand Designs". I think he might have a point. Not that I'm building anything particularly grand, but certainly about the windows. This is the outside prior to fitting the large window. The cladding job is going well, so we are hopeful of a good day. Having spent a few evenings fitting frames in the recent cold snap I think I ought to spend some time with SWMBO on valentines weekend. So I treat her to fitting the second largest frame in the house, and of course some glazing. It's because I'm a really nice person and like to share. The frame is 2.5 metres tall and 1 metre wide, designed to take a single glazing unit so I was particularly concerned with distorting the long edges as it was installed so we paid particular attention to shimming it correctly. I'm pleased to say that the Alien declared it to be straight and level after the screws were tightened. So concludes fitting the last frame in the first floor. The view of the site will be particularly good from the stairs. Now on to the glazing. We carefully plan how we are going to lift 49kg of glass up the scaffolding and swing it into the frame. We have a selection of glazing handles, ropes and platforms set up ready, and then I look at the glass in detail and announce that there's no way I'm fitting it. SWMBO then looks at the glass and storms off in a sulk. Not the reaction I desired, but understandable when you see the bars inside the unit are Y shaped and not straight. We then checked all the others, and found another with a dodgy bar, meaning 2 units out of 48 have a problem - not exactly achieving 6 sigma QA! I have to suffer on site with SWMBO sulking while we do some other jobs that need doing - all she wants to do is go home and be cross with the local window people, which I can understand, but it won't progress any of the handful of little jobs blocking the big day of seeing the house without scaffolding. I pointed out (in the words of one of the members here) if you can't take a joke don't start a self build. But this went down like a cup of warm sick. That evening we found what looks like water in the oil of the Range Rover engine. Happy valentines day Mrs dnb! Fast forward to Monday, and the photos arrived at the window supplier. His first words were "Well, they didn't try very hard, did they? I'll tell them to have another go and hurry up about it". I'm happy that it will be sorted out, but it's a bit more delay. We'll get there eventually... The last frontier for the cladding before we look at scaffolding removal. There's no point in hanging on to it for fitting the arch windows unless they arrive in the next couple of days. The window suppliers assure me that everything can be done from inside for these. I've always liked this view of the house.1 point

-

This is what I did. An old desk fan, a big sheet of cardboard, a lot of duct tape. A manometer to measure pressure difference between in and out. Measure air flow passing through the fan with an anemometer to calculate a rough idea of the leakage rate. And go round the house looking and feeling for leaks, I found very few. What was really interesting with the fan going is how the house depressurised, and if you then went and opened a door or window, the massive whoosh of air that came in to make up the pressure difference.1 point

-

Thanks, to you and all who've answered so far. I was thinking of giving stuff away in the hope of it having a second life, but it does sound like even that might be problematic. What I really need is to stumble across a fellow self-builder on a micro budget who can make use of all the stuff ...1 point

-

1 point

-

You set the roof out so you end up with an even cut at both ends, then you cut the first sheet longways and re bend the upstand, do the rest of the roof and if you lucky when you get to the far end you have the same size cut, cut this and again re fold the edge.1 point

-

Not sure where your FFL is related to the photo but I assume it is top of brickwork. Maybe look at removing the top course of blocks and filling cavity down to the foundation with concrete to get to your 140mm bearing. You could then run some coursing bricks and a course of Marmox Thermoblock as an insulated base to the timber frame.1 point

-

If it’s on strip footings, I would look at knocking all internal walls out and form an insulated raft inside the face brickwork the only part I would keep would be the footings and face brickwork. But it does depend on what you paid for it and if you have any height restrictions. Your neighbours version is woefully inadequate.1 point

-

Unless there is a really really tight planning restriction on the ridge height, I would simply raise ground floor FFL 100mm to add extra insulation. Extra wall insulation will mean slightly smaller rooms. Can you live with that? The BEST thing you can do to make this energy efficient is pay very careful attention to ALL the detailing, particularly air tightness.1 point

-

and if it is alarm, they tend to have an anti-tamper switch inside..1 point

-

It’s amazing what people will take when they’re getting it free, we had so many off cuts of insulation during our build and didn’t want to pay for a skip to put it all in, advertised as free to uplift and had 3 or 4 people with vans filling them up!1 point

-

Thanks for your thoughts, I will pass on and report back. I think due to covid restrictions no 'more technically' minded family member has been able to visit to investigate further and removing a screw to investigate (which is what I would do) is not something non-technical safety minded people do if they think something is electrical. Looked like a skirting board to me too but I will check if it is on the ceiling!1 point

-

or a previous owner took them with them when they moved.1 point

-

Facebook marketplace and Gumtree, under "grab what you want, it's free" and hope for the best. Usually causes delays, costs and inconvenience. Put the staircase on market place here on BH and see if anyone is building near you and could do with a temporary 'site' set1 point

-

As @Bitpipe says, you'll be disappointed in what can be salvaged and reused/sold. I spent an age dismantling our bungalow by hand, apart form the bricks, haven't found a use or interest in the slates, timbers, flooring etc. All the metal went to scrap. I would have saved a lot of money and time if I'd just knocked the building over.1 point

-

My instinct would be to remove that screw and see what's inside...1 point

-

And welcome Another passive house builder here (2016) not certified though but meet and exceed all the requirements. Quite a few here have achieved similar with different build methods. Tell us more about your project!1 point

-

Agreed. I've used both the diamond disc and cup types with a small grinder with great success on concrete (which is much harder than brick). I also shaped some brick slips to go over and around some flashings - the diamond disc went through them like butter. As you say, lots of dust, but a mask and eye protection should be used when doing this sort of thing anyway. @epsilonGreedy, unless there's an access issue, I'd have thought this would be a lot faster and likely leave a cleaner finish than using a multi-tool, although admittedly I've never used a multi-tool for this specific purpose.1 point

-

The sad truth is that very little of that will have any inherent value beyond basic scrap metal prices. We had a similar era building and could not even give away the 1500 unused and stored bricks from its original construction (original owner had kept them for a future project), never mind other bits and pieces. It has to be quite special to be of interest to a salvage yard, most stuff is not worth the effort to remove it without damage and re-condition for future resale. Also slows down your demolition and increases the cost. Good idea to keep rubble etc, perhaps look to hire a crusher if that works economically to keep such material on site and avoid it being taken away and then bought back again as type 1 sub base. Just make sure it does not get in the way of the build itself.1 point

-

1 point

-

Welcome and sounds like an interesting project.1 point

-

No idea what the blocks are, but i am curious why there is what looks like skirting on the ceiling1 point

-

To continue your analogy, you won’t be able to make your supertanker handle like a ski boat, so don’t try. Use it in the way that it’s able to operate. I have an old and predominantly poorly insulated house and an ASHP. The heating isn’t responsive, but it is good at keeping a steady constant temperature. So I had to move away from thinking of the heating working like it did in other homes with oil or gas boilers. My set up seems to be fine once up to temp, as my house is always at 21.5*c (even if away). It’s worth noting the amount of people who first turn on their system thinks something is wrong because the house is taking days to get up to temperature (some times 1 degree a day).. but that’s fairly normal. I thinking @ProDave said it took his house a couple of days to warm back up after going on holiday for a couple of weeks (in the dim and distant past).1 point

-

Oh and for the marks from the suckers I tend to use a upvc solvent cleaner and that should after a couple of cleans remove these.1 point

-

I would get the land valued as is Without any planning permission1 point

-

This one does not have an overflow fitting. https://www.screwfix.com/p/basket-strainer/975621 point

-

1 point

-

We have the aluclad with wood inside but our son next door has the UVPC ones and they are great- he wanted grey interiors anyhow. Our fitters were totally crap ( dont use Ecohouse internorn or if you do contact us about which fitters to avoid ! ) Do check with the JUliet balcony about the window cill. Internorn said there shoudl not have been a window cill as its a door! But a door no one walks through. If we had not fitted the cills ourselves the water would have been running down behind the render . Another thing if there are large gaps above the big sliders then dont fill with expanding foam - we did this and it warped the door so its hard to open even though we dug all the foam out . One question I had about windows is how do you get the sucker marks off the outside? Before the scaffolding went we spent ages washing the windows and they looked ok but as soon as there is any outside condensation you can still see the sucker rings1 point

-

IMO yes. When you need the most heat they are usually the least efficient. I would only fit an ASHP in a well insulated airtight house and I would use gas or oil in an old, poorly insulated house. Whatever source of heating is used, it needs to be sized correctly.1 point

-

1 point

-

Who said 100mm bearing, that is small and most end bearings these days have been increased.1 point

-

Doesn't matter, as it will make an excellent raft to sit the rest of the floor on. It's been in long enough to have settled, and will be fine to take the non point-load of a new upper deck. What's it like when you walk slowly over it? Any movement in the corners?1 point

-

As was said earlier, the price can be almost anything. If the electric company want some help upgrading the local network they will try to get you to contribute. Here is an example from 2003. I ask for the service pole that serves just my barn and my neighbour’s bungalow to be moved 3.6m back down the run of cable. It is on my land and will remain in my land in the new position. All I really want is the end stay to be in the new position. The power company spent six months dreaming up schemes that would help them. What they finally wanted was me to pay £12,500 for them to put up a larger capacity pole mounted substation on a local farmers land. They also wanted me to arrange and pay for wayleaves from that farmer and another neighbour. Naturally, we just dropped the whole idea. As long ago as 1980 we had to abandon a house purchase, it had no mains electricity. The asking price for the house was £8k but the quote for the electric supply came in at £10k and we had to do all the digging and put in the duct. £10k was a lot in 1980. more recent example, last new build was 2012. Electric £3800, water £2900, gas £380. Like you, adjacent to a highway, max dig was 10m for the electric because that was in the far verge. Gas was a false figure, their plans were wrong and it cost them way more than that but they did honour the quote. That was in North Yorkshire.1 point

-

+1 System boiler and possibly a mains pressure H/W tank of some sort. Spend money on insulation, better windows etc. If you like gas for cooking then consider a dual fuel oven like a Britannia Range connected to a 47kg Gas Cylinder (or two on an auto change over). Cylinder Gas is too expensive for heating but the amount used for cooking is small in absolute terms. A 47kg Cylinder costs about £60 and lasts us 18 months (family of four). The oven is electric. Other companies make similar.1 point

-

If you're in an old house without the option of gas I would stick with oil. I would fit an external system boiler in place of the combi it would be quieter and more efficient. Try reducing your usage by insulating, draughtproofing etc. https://www.tradeplumbing.co.uk/grant-vortex-blue-external-floor-standing-regular-oil-boiler-erp.html1 point

-

XPS will cause plasticiser migration in cables same as EPS - keep them apart!1 point

-

Well done to you Andy. For all there is a lot to what Andy is doing. ICF etc, sounds like there is a big opening in the front. Although it's done under PD what Andy is doing can add a lot of value to the property.. if it is done right. Imagine it's just an extension not connected to the house. It's also a great way of cutting your teeth which can give you confidence to tackle larger projects if you fancy it. Andy.. sounds like you know what you want so maybe no real need for an "Architect" per say. Many of these "garden buildings" now have a big open front on the high side with bifolds or sliding doors. What you now have is something akin to an open sided, often mono pitched farm shed with a set of doors on the high front elevation. What is required here is to make sure that when the wind blows the building does not fall to the side in the plane of the doors. Here what you often do is to make the side walls, roof and the back wall are stiff. You can try this at home with a cardboard box. Cut out one long side, tape it up along the seams, down to a table and push it along the plane of the doors. You'll see it wants to rotate so if you brace the "gable" it works. For the technically minded this often called a complimentary shear effect. To square this circle the SE will work out the wind load and put bracing or use the panel stiffness on the gables, back wall and roof to show that it works. You'll need to make sure the building is fixed down to something heavy as it also wants to lift up in places. Andy if you can get all the data on the panels, slab and put this into a document. The more info you give the SE the less they need to guess and so on. Also, get the details on how the panels are connected together. No point in having the panel data without the info on how they can interact and connect together. It's a big learning curve to become competant to prove this calculation wise but there are SE's that will do small jobs for enthusiastic beginners so don't loose heart when searching them out. If you do the donkey work on gathering the info then you may get a cracking reasonable price from an SE. One last thing I have observed is that sliding doors need some kind of space above so the roof / lintel over can deflect down. This is a traditional deflection head detail. But I was talking to some fitters of bifold doors the other day and they want to pack the head of the doors tight to stop the mechnism at the top coming loose?1 point

-

@JamesP we’ve gone round and round on metal roofing. But back looking at Colorcoat. We actually have a very simple mono pitched roof. Slight complication on the abutment and we are right down there at 5 degrees ?. That said we also have two “flat roof” skylights. How much of a challenge was fitting skylights in? And where should I look to lear what’s required? Cheers1 point

-

1 point

-

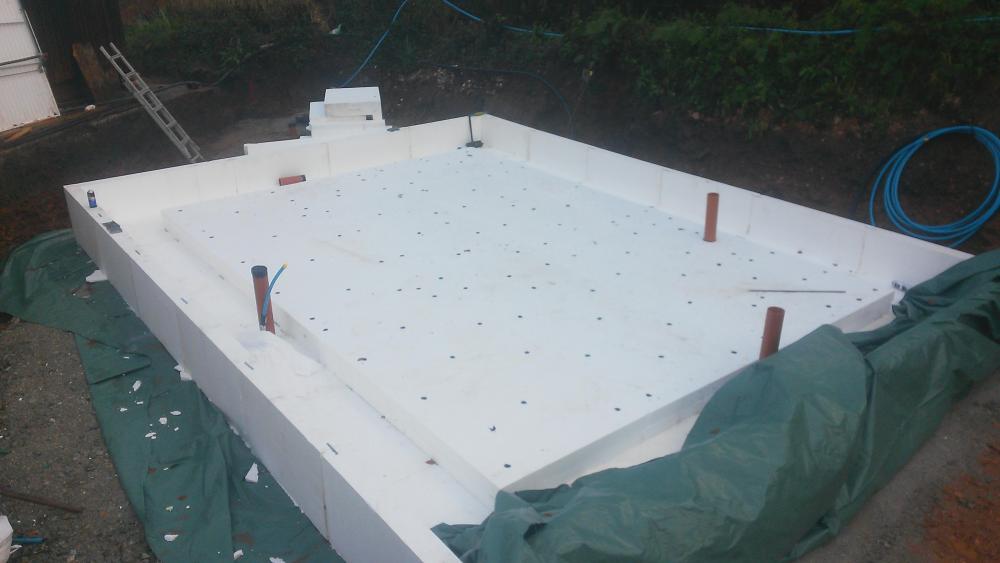

Hi Walls are going up a lot of shifting about as small sight and no space and access for forks so all hand ball. Should be ready for the first pour this coming week. I have the bracing and rebar to cut to be ready. Looks like we may get some dry days can`t believe the rain we have had since we got started.1 point

-

I still think that BuildHub should open accounts at most suppliers so we can all get discounts easier. Mentioned it before, but it goes against the 'no commercial involvement' mentality. Could help with importing stuff from the EU if it was a company. Oh hang on, most on here voted to leave.1 point

-

1 point

-

Hi and thanks for the welcome. Its a two story build but on a small plot next to a bungalow on a sloping sight so have to dig down a lot. So have gone for the isotex insulated raft and blocks as some is a retaining wall. So not low embodied carbon but hope to have very low emissions. I will up load some plans and pic later today we just managed to get the raft in before Christmas after shifting 400 tones of soil. 2202 - (BR-)04A (1).pdf 2202-(BR-)01C Floor plans.pdf1 point

This leaderboard is set to London/GMT+01:00

.jpg.dd4c75263a0089f89a7334c8fe0cd55f.jpg)

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.jpg.dc0ec5c09b16f0aa0fefa15f24b82090.jpg)

.jpg.760092cc542264770084381d9147c191.jpg)

.jpg.d9610510dbfc5d6538747e870b0cbb36.jpg)

.jpg.c45ddf359ba41e38a62e54f00de626b3.jpg)