Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/21 in all areas

-

Totally agree about the inspiration being up there with Ben Law's -- it not just about what they achieved, but their attitude to the build, problem solving, and life itself. I did come away with it exceedingly frustrated though, largely on their behalf. If the planners hadn't placed such ridiculous and counterproductive constraints on them, not only could they have achieved an even better result at less cost, but they would have caused themselves less stress, less risk of serious harm to health and financial ruin, and also achieved a far far more efficient building executed in a more environmentally responsible way. Hand digging and then pouring hundreds of tonnes CO2 belching concrete in order to "preserve" a few totally rotten 30 year old timber beams is completely and utterly bonkers. And then making steel boxes for them! One of the key reasons to use wood in the first place is the low environmental impact of generating and recycling it. If it's past its useful life, rip it out and replace. Preserving it is in absolutely no ones interests in this (and most!) cases. I fear all the effort in underpinning and preserving the super structure means they had to cut a lot of corners with insulation thickness in the floor walls and roof. If rebuilding they could have achieved a lot better fabric, with less time (and probably less cost), and got an identical looking result. And while they're inspirational, it was easy to see many times a small change of luck/fate could have resulted in a devastatingly different outcome. Their incredible perseverance got them through, but millions wouldn't and my goodness the fact they did doesn't justify the pain that society needlessly and pointlessly throws on anyone attempting this. More selfishly: I'm much more in the camp of "pay someone else to solve my problems" just because of the number of hours a day my main job takes up, but even so I've found the last year utterly tiring and stressful so it's humbling to see what real dedication to a build + day job + family looks like and undeniably makes me disappointed in myself that I'm not able to do a better job of juggling them. (And candidly, I think another hour of footage and Greg would become my first ever man-crush, so of course that made me angry at myself too ?) Back to the main point though - we must be the only country in the world that goes to these lengths to preserve rubbish, just to enforce some sort of faux design constraints? Every other country must surely looks at us and wonder what the heck we're smoking. If we really want to make some portion of our rural properties look like agricultural buildings, lets as a nation have a grown up conversation about it and make some sane rules to work towards that. Requiring people to build sheds and then "preserve" and convert them is just making substandard accommodation that only the wealthy (or ridiculously ambitious) can achieve. I mean, beautiful as it was, their end building didn't look a thing like the barn it started with anyway. Did the planners do this just out of spite?5 points

-

If some one posts something that contains a term or a technical aspect that you don't understand you could always Google it first before you respond. Only takes a few seconds and it will definitely help you understand what is in the post which will then help you reply with a clearer idea of what's going on and what needs to happen. As far balancing rads, it's just the term that has been used for years ,Peter didn't invent it.3 points

-

Online, you could not want for a more patient, polite or kind environment in which to share your build challenges. Look at the page count. Re-read just some of the members' responses with care. Work out, briefly, how much time you have been given by BH members - for nothing. Generous does not even begin to cover it. Build Hub is not the only online resource in this sector.3 points

-

Much as this cannot be done in this case. If you ignore environmental concerns, electricity is considerably more expensive than gas. On my tariff I am paying 2.14p per kWh for gas and 14.29p per kWh for electricity, so electricity is 6.6x the price of gas. Thus with an 85% efficient gas boiler and an average COP of 3.3 an ASHP would be around 70% more expensive for heating than gas. People are perhaps being sold ASHPs as a cheaper way to heat their homes. They are absolutely not cheaper than a gas boiler if you have mains gas available. However, you get a generous RHI payment for an ASHP and you save on putting a gas supply in and on having two standing charges. So this evens things out, especially the RHI which will make the ASHP cheaper for the first 7 years.2 points

-

This is not a paid for professional service where you might properly expect measured responses from all contributors. Nobody can know exactly what's meant by written text. So much gets - as you say - lost intranslation. Thats normal. This board is a teaching and learning resource. It does not offer a Members' Needs Analysis such as those offered by other online teaching formal, paid for teaching institutions . So respondents to your posts cannot know what you dont know. But, out of kindness, they respond anyway. Thats why it is very suprising indeed that you react with visible frustration at the perceived quality of responses. One technique which is very powerful in online teaching and learning is to ask the person posting to summarise what he or she thinks she has learned. As a simple post - just bullet points. That does three things, It reassures readers that you have made an effort to understand them It allows time for you to internalise some of the teaching Its helps set the agenda for further development. Try it. Please.2 points

-

Once you have read the heritage house website, you will, hopefully realise, that with a compromised DPC, you are not fixing your damp issue, merely covering it up. With a DPC on the inside, and EWI on the outside, your wall will be wet forever. As one of the videos says, if you wash your clothes, put them in a plastic bag, and hang them on the washing line, what do you think will happen. This is, effectively, what your proposal does. Either you need to fix the dpc properly, or treat the building as though it doesnt have one. The fact the floor was rotten says you have a problem with moisture, Dumping a load of concrete in there wont fix it. You need to understand the reason why first and work from there.1 point

-

Page 8 of the manual shows you how to adjust the "water outlet" temperature.1 point

-

Balance: noun 2. a situation in which different elements are equal or in the correct proportions. So you proportion the available heat according to the variables of the room; how quickly it warms up, loses heat and so on. You do this via the lockshield valves on the rads.1 point

-

I must admit I've moved on myself a couple of times but have always returned as I'm interested in the subject, can always learn more from others and, more to the point, don't like to think of anyone being persistently cold as that's no fun at all. Very frustrating though.1 point

-

No problem, and I'm glad you read it - I'm typing on a phone and might've exploded if you'd just dismissed it and kept on going about dictionary definitions of the word 'balance'. For what it's worth, radiator balancing can be mind bending even when you understand it - particularly if you overthink it rather than just go through the right process (which is iterative and can take a while). It is really important though - or at least highly desirable - but often isn't done, properly at least. Many just twiddle a few knobs until everything feels hot and leave it at that. That's fine; they get away with it but this is largely due to the nuclear reactor they've got burning away at the front. You haven't got that luxury (I say luxury; they are unnecessarily overpaying due to the inefficiencies running like this) and so you need to get the most out of that heat pump you've got and be able to quantifiably determine whether you are getting it or not. Even just simply confirming that whilst you've set it to 55C is that what you're getting?1 point

-

Ok really appreciated this explanation MJN. It'll take me 10x reads of it to understand tho, a heck of alot there to absorb & for me to make sense of, and I will ask q's if i still dont get a part of it.. but I'll go through this info tmrw. cheers zoot1 point

-

Whilst there is indeed no cold water introduced you must remember/realise that the radiator is extracting heat from the water and transferring that heat to the room. If you throttle the lockshield (which is usually on the return) then the flow through the radiator decreases and allows more time for extraction to take place. Too slow and it'll fail to deliver its full output. If you open it up then the amount of heat extractable increases but do it too far and it'll exceed the radiators capacity and that heated water will return to the heat pump. This 'wasted' flow could've been of more use elsewhere ie run through radiators that are getting insufficient flow to them. That's where balancing comes in - tweaking the flows through each radiator so they get the right amount of flow for their size/capacity/location, ensuring there's enough to go round, helping rooms heat up at the same rate and (for boilers at least - don't know anything about ASHPs) increasing efficiency by minimising short circuits and enabling condensing boilers to extract even more heat from their condensating ability. A thermometer on the flow and return will enable you to observe the effect of adjusting the lockshield, and the former will also tell you if you really are getting water at 55C to all your radiators.1 point

-

I had to cut a bigger hole to get at it all and have started to fill it in. I have started with expanding foam right at the back where the pipe comes through the PIR and where the PIR goes around the corner behind the wall to the side of the MVHR duct. My plan is to do it in two layers, one sealing up the PIR and another one in front inline with the missing blockwork. I have made a start on the rear layer and am going to let the first can of foam expand and dry before I see if I have missed anywhere. I have bought 10M of 6mm ID 8mm OD pipe to attach to the foam cans as I have had the issue elsewhere that you cannot get the can close enough to where you need to fill. The is exacerbated by the cans needing to be upside down. If you attach a couple of feet of flexible pipe you can keep the can out of the way. The first time I did it I thought I would clean out the pipe but that was pointless, so I bought 10M from EBAY on the grounds that I will use about 60p worth and just bin it each time I need to get a can of foam into an awkward space. I also recommend proper disposable latex gloss and not the thin ones supplied with cans of foam. The foam comes through these as they have little breathing holes. I took a picture with my hand to give you an idea of the size of the hole in the inner blockwork. If you look at the pic you can just see the block to the left of and in front of the ducting and the edge of the block to the right of the ducting. This whole section of inner leaf is missing. It was above the ceiling but the ceiling has various penetrations for lights etc and also connects to the area behind the WC where the cistern is. It must have had quite the impact on the airtightness test I assume. Between the cupboard and the WC there are 5 lights, 2 sensors, 2 sockets, the WC wall fittings and the WC flush plate all where air can get through.1 point

-

Double charged could be what they are referring to. That means they get double thickness of the glaze or pattern applied. @nod may be able to elaborate a bit more.1 point

-

I'm out of hours now, but itching to get back when I finish this place. Being able to take a joke when it hurts your / bank balance / loyalty / ego / muscles / brain / feelings is a hard-won set of skills. And applicable across all sectors, professions and trades. And I'm glad (now) of all the aggro I've had in years gone by. Almost all of the serious stuff, was far worse than my collapsed wall, or leaking roof, or run-ins with duplicitous plumbers. Humour levels. It also enables you, on occasion and when appropriate, to growl in peoples ears with suprising levels of authority.1 point

-

Yes . I found one lying around but it’s 1 1/2” ; need quarter inch . Ordered it will try that first ?1 point

-

Can’t comment on the above apart from making sure you have a good noggin in the wall to fix the radiator to. my cast iron rads have 10mm rods going into brackets fixed to the walls. we used a few 4x2’s to get a decent fixing1 point

-

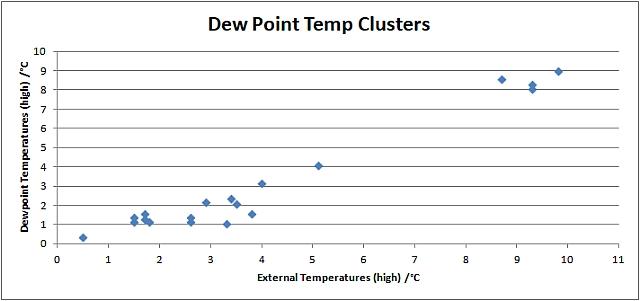

Just before I go off to work, thought I would have a look at your local temperatures. Got some data from Whitchurch, which is fairly close to you I think. Looked at the highest air temperatures on any given day, and the highest dew point temperatures on the same day. Then plotted them. This will give the best case. Time period is 28/12/2020 to 15/01/2021 As the majority of the data points were between 0°C and 4°C, this is about the worse point for an ASHP to be working (there has been a few comments about them freezing up)1 point

-

1 point

-

"Total Design Heat Loss 8594W" Assuming that is how much they have calculated the heat loss of the whole building to be and assuming we are at the coldest temperature now so you will be running at that level at the moment. also assuming that is all delivered 24/7 So 8594 at a COP of 3 for the heat pump, would use 2864W of electricity. So in a week that would use 2.864 * 24 * 7 = 481kWh. Then add on hot water heating and "other stuff" and your total usage for the week does not unfortunately look unreasonable.1 point

-

Agree with Steamytea, check immersion heater and everything to do with Hot water, that programmer if any isn’t on constant/ always on. should be regulated by the thermostat in the immersion heater cover but worth a check anyway. plus the electric shower will swallow a few units of electricity. Process of elimination, Sherlock Holmes style!1 point

-

Yes, but not the end of the world depending on the fixing type. Yes - only hand tight - if you overtighten the rubber o ring will be forced out and they will leak.1 point

-

I didn't even know they had prices on the shelves! You must have nice ones round your way. That said, nothing I want is ever out on a shelf anyway as if it was I could work out for myself if it was the right thing and then run the risk of sounding confident at the till - could probably game the system if I remembered to go in my scruffs at the crack of dawn. Ah, yes, the discount. Forgot about that. I think it goes something like: Discount (didn't ask for one: x1, asked for one: x2 then /2)1 point

-

As an aside, our build used a lot of electricity for the first few months and I put this down to “warming” the build up and drying out. Ours is set to 20/21’ now.1 point

-

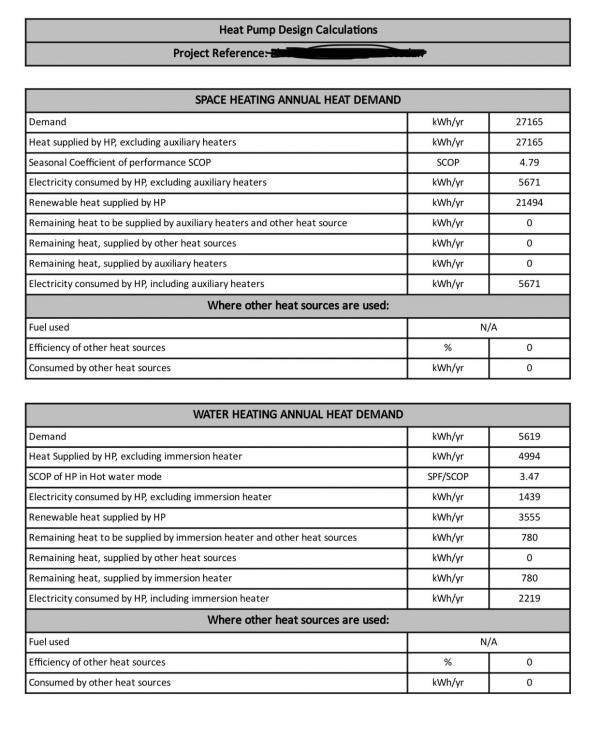

Did your installers not do a heat demand summary? This is the first page of the summary I received from an MCS installer when I asked for a quote. It was produced using the MCS software. If it appears to be using much more electricity than you were led to believe I would contact the installers. Heat pumps are designed to be used pretty much constantly I believe but if you move to a variable tariff you could raise the temperature to higher than you need during the cheap hours so it does more work during the cheap rate and then set it back during the more expensive period. I’m on a flat rate tariff of 11.5p for heating and 12.59p for all other use with EDF. I don’t have a heat pump yet (still considering one) but am on all electric heating. I’ve never set the heating to 22 degrees though. I have it at 18 in the bedroom and between 18 and 20 in the living space.1 point

-

By working out the heat loss for your construction type. If you had a SAP done, it should be o there. Or just work out the numbers from the areas i.e. floor, walls, windows, doors, roof, hove much insulation they have, that will give you the U-Value (eventually), then find a local weather station to get the last weeks figures, then work out the temperature differences, multiply that by your overall U-Value, multiply by hours in the week, and hey presto, you have your theoretical losses. So say you have a 10m2 wall that has a U-Value of 0.2 W.m-2.K-1, and the first two hours of the week had a mean temperature of -1°C, and your internal temperature was 18°C. Then: 0.2 [W.m-2.K-1] x (18 - -1) x 10 [m2] x [ΔT] x 2 [time in hours] = 76 Wh. Tedious, but useful, it is why we have spreadsheets.1 point

-

1 point

-

Make a brew and get a pack of digestives out and have a long read of Pete Wards website. He’s incredibly knowledgeable about old houses and buildings and his explaination of “rising damp” is well worth a read. https://www.heritage-house.org/damp-and-condensation/types-of-damp-what-have-i-got/what-is-rising-damp.html1 point

-

Hellfire mate! Something I can help with. Yes there is. Geberit Wandklosett Flexible PE Sheet 90 x 90 MM, 241521001 Made my eyes water in terms of price. Annoyingly, unavailable currently on Amazon. If you need to get it from The Fatherland, I'll dig around a see if I can lay my hands on one. No subtitles needed ?1 point

-

Thanks for a very quick response very helpful - the files are currently stored in a barn with big high security locks and solid stone walls with no openings good security and she is indeed registered with ICO and this is compliant, we did have the files stored before externally at a unit but now we are in the middle of nowhere in Cornwall there is nothing locally she often needs to refer to the records as cases progress so needs access. the new store will not have any windows just some ventilation and made from SIPS panels with wooden cladding and a strong door and security locks and thus will meet the ICO guidance - she has special bespoke insurance for the records as you are correct not covered by our house insurance. Increasingly the data is electronic but a lot of NHS records are still paper only sadly particularly the hospital records1 point

-

Ground cover plants are good at holding earth on a slope. ? thinking about this, I remember years ago being told that black mild steel is best fir this application, should be cheaper than drawn mild steel and is used by major gardens such as National trust, RHS.1 point

-

1 point

-

If you are doing that you should specify the materials to the contractors so you know you are comparing the same products. i.e. tell them that the consumer unit is to be Hager, metal clad, 20 ways, each circuit to be protected by RCBO, SPD fitted at incomer etc. Supply part numbers. sockets- MK Logic 2 Gang complete with appropriate back box and noggin/dwang to suit, so when they fit a 25mm box and it doesn’t fit cause the MK spec says minimum box depth 35mm they aren’t hitting you with extras/day works/variations.1 point

-

I agree entirely, I always am grateful for the help. But its innevitable things 1. get lost in translation using a box of text to and fro, 2. occasional posts are missed/ im not prompted by like yours just now, id say 5% are. 3. If im trying to understand X for the 1st time, & its commonknowledge to most, frustration at me not getting it happens, & 4. if in actuality its balancing the room temps that is the aim, by in fact un-balancing the rads (from a state now currently balanced: balance ONLY EVER meaning equalibrium, A DEFINITION) in order to achieve this term "balance radiators" is then an utterly preposterously stupid term, and I should be cut some slack at being confused by it, not ridiculed & sniped at like many posts. Yes there's mostly patience, but alot of unwarranted impatience suddenly errupts too. Joe90, Jfb, Peter Stark should be commended for never getting angry, a calm manner I think realise Im new to most stuff, & are patient. Thanks . Zoot1 point

-

Just checked with Parker’s and 150x6 flat stock is £12/m plus VAT ex works. That is for lengths at 6-6.4m long.1 point

-

Four years ago we paid :- 6 * 2.5m x 150mm £369 13 * 2.5m x 100mm £550 Including VAT and delivery.1 point

-

Welcome. Good luck with the planning aspect of things. Since this is your first post could I suggest you have a look through the planning threads? And also have a play with the search facility on the site: its very powerful To help you, as an example, I've done three searches for the topics you highlighted in your post above - and link to them below. Metal stair cases Bi-fold doors ( You might try different spellings of bi-fold ) Kitchen Islands You are starting out at a difficult time - BH is a very supportive group though. Best of luck. If you want some walk on glazing @pocster has some , and don't worry about @Russell griffiths, he's actually quite tame. ?1 point

-

It's the rate at which heat is lost through a material. It's difficult to model accurately and there are endless constructions to reduce the effects. The effects are more pronounced where there can be a build up of heat on the outer surface such as on the walls of a well sheltered house. Where we are, near the coast in an open area, the effects are non existent because when the weather is hot there is always a sea breeze. https://www.greenspec.co.uk/building-design/decrement-delay/1 point

-

If it 22VAC off load and you're only seeing 5VDC out of the bridge, there's a short somewhere IMHO. I'd be removing the supply from each of the op-amps and from the two cards, to try and pinpoint it.1 point

-

Credit where it's due, throughout this thread he's not been shy of showing his cock ups.1 point

-

1 point

-

I used Contega PV to join the membrane to the wall, Solido looks like a different variant of that product line. The fleece holds the plaster well, but the tape is so-so: I managed to remove it easily when made a cockup, something I cannot say about normal tapes (Proclima or Gerband). Regardless, with Solido you'll end up paying big buck and having thick skim to cover it. I'd look for some sealant instead - I use https://www.soudal.co.uk/pro/products/sealants/acrylic-sealants/acryrub-sws/acryrub-sws-310ml around windows, it's airtight and paintable, was about £3 per tub. You can check their Acryrub line for something with less flex, so potentially cheaper. Or other supplier for that matter, CT1 seems to have some good fame here, though not sure if paintable/plasterable1 point

-

At the simplest it is the time taken for energy at the outside of a wall to transfer through to the inside. https://www.concretecentre.com/Publications-Software/Design-tools-and-software/Dynamic-Thermal-Properties-Calculator-(1).aspx from the middle of the link :-1 point

-

Save yourself a headache and fit it after you got a completion cert.1 point

-

Google found. https://www.radwell.co.uk/en-GB/Buy/CARLO GAVAZZI/CARLO GAVAZZI/FPD1901220 But its expensive. They offer to repair one for £177.1 point

-

Stainless towel rail and Duel fuel it with CH and thermostatic electric element. I've bought stainless rails for £160. 1200mm X 600mm (As intimated above) If you've got MVHR just pop an extract in the space, doubt you'd need any additional heat.1 point

-

1 point

-

Just bear in mind that anything off the heating system will only provide heat when the heating is on, as opposed to the traditional airing cupboard housing a dhw tank. A small electric tubular heater might not be a bad call, maybe switched by a humidity sensor so it only runs when you need it?1 point

-

i really detest the current fad for a massive open lounge and kitchen combined.1 point

-

it also depends on which system you use to fill the concrete. The choices are: 1. One large pump that arrives onsite to pour everty 7 courses - I believe you are going ISOTEX 2. Crane onsite which means you can pour every four courses and removes the need for bracing - small self erecting style. If I were you I would speak with Jamie about the two approaches above and based on the 6 house development they are completing in Marlborough right now, using the crane, it is definitely the way forward. We spent a great deal of time on bracing which could have been saved if we had an onsite crane. Plus with the crane onsite you move other materials around the site as well. Whatever information you get it will only be a best guess; the weather also plays an important role in determining progress1 point

This leaderboard is set to London/GMT+01:00