Leaderboard

Popular Content

Showing content with the highest reputation on 10/21/20 in all areas

-

Overall it went swimmingly well, couple of minor issues but soon resolved and need to return to sort out a handle issue but John Knight Glass were, IMO really great and for final sign off we wait for contact over next couple weeks when someone else comes to site to check everything with us so enough time to raise any snagging issues hopefully. Despite some panic on the canal bridge when the trailer was about 8 inches off the floor, everyone held their breath when the glass got over successfully. The other option being discussed was asking CRT who were dredging at the time to transport them to us. Although that didn't happen, I'd of been quite pleased to see that ? The windows we picked were the aluclad UPVV studio KF320 windows and KS430 sliding door and we are more than happy with them. A couple from work in progress. It was nice as the sun was setting getting some pictures of the house today, finally with the windows.9 points

-

Now we’re talking bruv’ I think from the “others” it’s been established it’s not worth it fiscally at least in the short term . I equally was going to have RWH - but as you say payback would be 1 billion years . I actually wanted to produce my own drinkable water from rainwater , but again it just isn’t viable . Looked at pellet boilers for years - before I even began my build . Don’t mind the high initial costs ; but storing pellets is problematic and they just track the price of gas . I want *some* lecky that is free be it pv , wind turbine or my own nuclear power generator ( I’d love one of them - especially when it goes wrong ). Some of us lead . That means mistakes and bad choices will be made . But we pave the way for you lesser mortals to follow . ”This is the way” as the Mandalorian would say . You people are standing on the shoulders of giants ( no emoji exists to demonstrate my complete smugness )3 points

-

it's important to some but not so important to others. for me on some things it's not important at all but on other things it is. e.g. we're having RWH which will never repay itself in a 100s of years at the current cost of mains water but we want to reduce our use of mains water so those that need the mains water more than us have it available to them. and some people just like new toys and tech to play with! I'm one of those and I get the feeling that @pocster is as well. obviously, budgets play a major consideration and some don't like to frivolously throw money away on things. personally, I want to enjoy my life while I can. having seen my brother suffer from heart attack and stroke at 45, my father pass away 3 years after being diagnosed with MND at 73 and my mother taking a massive downturn in her health due to heart failure at 76 I'm now thinking that life it too damn short to worry about stuff like ROI or payback period etc. As long as my kids have an education (and a habitable planet to live on!) and I can leave enough equity in my estate to help them when I finally go I'm all for enjoying it all now! I guess I'm very fortunate to be in the position financially to allow me to do this and others aren't and I get that. horses for courses and all that, right?3 points

-

I have a standing seam aluminium roof on a single storey part of my barn conversion, I fitted it in 2011. Because it's easy to keep an eye on, I noticed the exposed plywood of the deck was delaminating, and a fungus appeared. At first I blamed a bad drip detail and tried to fold the drip edge down further, but on a subsequent investigation I found I could lift the bottom of the panels because the plywood had degraded to compost. It was not going to cure itself, so I carefully unclipped the aluminium panels to reveal and replace the rotten ply and make any other repairs. What I noticed is that where the aluminium is in contact with the stainless sliding clips there is evidence of corrosion, to the extent that there is complete perforation of the aluminium. The holes are small, about 3-4mm, but almost every panel of 15 is affected. I fitted the roof to the instructions of the suppliers. The aluminium sits directly on the roofing membrane, which is standard breathable Permavent Eco. I can see from the staining that condensation on the underside of the aluminium gets trapped in the membrane and soaks the plywood, but also allows a galvanitic corrosion between the stainless fixings and the aluminium. I was going to reinstall the panels, lifting them off a replaced breathable membrane to allow the condensation to drain. But it doesn't seem as straightforward as that anymore. It is outside of any guarantees. My thinking is that this type of roof is used widely by other self builders. 9 years, or less is not a very good lifespan.2 points

-

yes as long as there is a good seal on the vacuum and nothing else in the duct !! Can’t do it once you have a cable or a pipe in there. Ideally, every time you pull something through such as a cable into a duct, you should also pull another draw cable with it. That way there is always a way to get another cable in.2 points

-

2 points

-

The majority of people on here, and in the general population, can't understand how to take advantage of E7, so anything that 'they have to tinker with' is a non starter. Let's face it, most people on here, and nearly all of the general public, don't understand how electricity is made and distributed, they think it comes from Unicorn Fart. If you tell them that during the day, the Unicorns are doing some other things, like powering offices and factories, so the only way you can get more is to pay extra, but tomorrow those times will be different, as the sun has come out, they will get very confused. So yes, people just want a simple installation and operation. My computer has 287 commands built in at the command prompt. I use 2 of them, (cd and copy). That is 2 more than most people, in the world. Things have to be simple from the outside.2 points

-

The good thing about being a Luddite like me is if we have a power cut I get to read a good book by my rechargeable work lamp and listen to my rechargeable work radio sat in front of my wood burning stove, the only thing that needs resetting is the clock on the range cooker. (And my android mobile phone still works ?).2 points

-

You leave the ducts covered in the slab by 10-15 mm so it's easier to break them out. You just tap the concrete at that area and it will sound hollow then you know your there. A few more strikes with a hammer and bolster will remove what's on top. Not a big job to worry about.2 points

-

Yes, indeed............ but, Lets all count how many problematic power cuts they've had in the last 5+ years, well, any type of power cut for that matter? Percentage wise, it's a micro-figure. Just about every offering is AC coupled / retro-fit and only some are incrementally up-scalable in sensible increments ( 2.4kW hikes ) to match the system accordingly to your ACTUAL needs. The Tesla is a one-size-fits-all solution, yes, you can bolt another on, rolled out for a nation of T-fans with a simple sales ethos of 'copy / cut / paste / repeat' and at 13.5kWh for the V2 you will need a serious amount of excess PV to warrant its purchase. If that has not had its fill then of course it will gulp grid electricity to maintain its condition / happy minimum dormant state ( and it's been well discussed that using the grid to charge a battery, with a limited lifespan, is not economical. It CAN be done, and certainly gets mentioned by my clients during discussions about storage options, but the maths just don't work out as you'd ( simply ) be better off strategically buying power direct from the grid instead. A 15% loss of overall efficiency is the first gotcha, just with the additional conversions from DC to AC and back again, but the sheer size of the V2 is the biggest design gotcha where you must be able to demonstrate a large amount of PV is routinely available to mop up with such a big battery. Limited throughput is the final nail in that coffin for me, because if you end up routinely using the grid to condition the battery you then start to chew into its life expectancy. Read the small=print Add to that the fact you can only charge and discharge that whopper at a factory-governed rate**, then it's like having a giant set of lungs but a drinking straw for a windpipe Can the Tesla be successfully deployed in a residential setting? Yes. Does it require a lot of thought and for you to do the sums first? Yes. Do people just LOVE the Tesla and don't really care about any of the above? Yes, and double-yes. Disclaimer: @pocster, this is not a dig so therefore this sentence stops you from giving me a ear-bashing SolarWatt are nearly unique in the way they work. DC coupled for starters, and scalable ( like Pylon-tech and a few other Chinese / budget offerings ) in 2.4kW increments, but the party-piece is the decider for me. During times of no excess PV availability the SW battery is warrantied to simply drop to its hibernate level and do just that....hibernate. No need for it to randomly steal from the grid to fill its boots, so about as efficient ( and simple ) as it gets. Also then very easy to understand its expected efficiency as grid load-shifting ( the correct / most strategic employment of ) eg when it becomes a necessity over the 'winter period' when PV is at 25% or less of it's stated output ) is not in the equation. ( The EPS function is on its way BTW!! ). Add to that a very clever BMS and a multi-scalable format ( you can add more command units as well as more batteries **which will double or treble the charge and discharge rates and it's win win AFAIC. I certainly wouldn't forgo those qualities and sheer robustness / elevated efficiencies to get an EPS I'm likely to never / rarely use.......bearing in mind that you have to be in the house at the exact time of the power cut to manually swap the EPS selected circuits over ( unless you further invest and pay to install Tesla's autonomous EPS changeover doo-daa ( aka expensive must-have ornament )) which has a 5+ second delay before kicking in...... There is a better way, but the DC has one Achilles heel ( thank f.u*k for that says @pocster ) which is it is not really suitable for retro-fit and needs to be included early on in the M&E design. End transmission.2 points

-

at last got a reply to my pre planning -which is basically positive with lots of hoops to jump through but at least we can now start to make plans so maybe i won,t need to include plans for my tomb after all1 point

-

We ended up with two 110mm ducts in plant room for condensate/UVC overflow, just because this was easier than trying to pipe the condensate from one side of the plant room to the other. Ideally you don't have lots of SVP junctions under your slab, but using Y-junctions for drains that aren't toilets or kitchen sinks is acceptable. The is a NHBC guidance document called "‘Y’ JUNCTIONS IN DRAINS UNDER BUILDINGS" that talks about this. 110mm SVP pipe supplied and installed by MBC. If you need 32mm depends how many concurrent high-pressure showers you want to plan for ?. Costs a lot less to upgrade to 32mm now then do it later which might be impossible, is my POV though. I don't know if most, but some people do. We felt it was the best approach for us. Depends how far away ASHP is, if you want it highly insulated, if you are happy to cement it in, and if you can go down under harcdcore to acommodate the bend radius or not. Clearly if you UVC is on an external wall, then this might make less sense and/or be less practical. The bend radius is about 0.5m+ from memory. Order pipe from https://www.loco2heat.co.uk/. Photo here. Note the long run is to a garden room, the short run on the left is for the ASHP.1 point

-

@nod The picture helps a lot. Is that a metal strap spanning across the first two trusses then fixed to the blocks?1 point

-

We design our stove to be bang in the middle of the house. I didn't want a flue pipe visible so we surrounded the stove in dense concrete blocks. The plan was to go all the way up to the ceiling but we stop halfway and boxed in the remaining part with a stud. The blocks hold the heat for the night and the next morning the house is still warm1 point

-

We haven't ordered this yet. But Latham's was a lot cheaper than Principal Doorsets. Also, you don't necesarily need the PH version, the standard version is stil pretty good from u-value perspective and was £1,685 at the time (vs £2,200).1 point

-

1 point

-

It was like a big spider! They have left it on site overnight and I was admiring it. Very nifty piece of kit.1 point

-

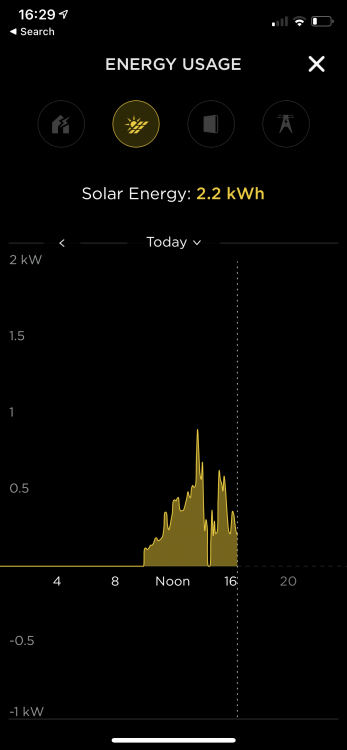

My immersion heater is a nominal 3kW but in practice seems to be about 2.8kW. The PV can generate up to 3.68kW. So if nothing else is on in the house, the PV can generate about 700W more than the immersion heater can absorb at 100% duty cycle. That's when most accidental export occurs. I do have the PV dump controller set to turn on a 700W panel heater that in the shoulder seasons can absorb a little heat into space heating but that gets turned off in the summer.1 point

-

1 point

-

Not on the North side of a building, yes, over the limit for code 4 but no problem yet. I normally do 1.2m long = 1/5 th of roll cheated on this porch 1/2 3m roll top lap will be cut to the left a bit and plumb1 point

-

I heard about a trick of sucking a plastic bag attached to a cord through a duct with a vacuum cleaner. Does that work in practice?1 point

-

If you have "loop at light" it's easy to pick up a permanent feed and use a wireless alarm. But not if you have "loop at switch"1 point

-

Looked again at Tesla tariff 8p kw for you @Thorfun 11p for me as I have no Tesla car ... But a little birdy told me some Tesla energy plan update has occurred ! . I’ll find out tomorrow and shall report back !!1 point

-

They are Hep2O to brass by the looks of it. https://www.toolstation.com/hep2o-male-adaptor-brass-socket/p545351 point

-

1 point

-

Now how did I know you'd be an Apple iPhone man. 99% of the population go into these 2 categories 1) Apple products, Tesla products, intelligent , forward edge thinking people. or 2) Android products. Simpletons . Pie and mash every time. Slippers, pipe, stout. No ability to think forwards or backwards or in any other direction. Soon to be extinct by natural selection.1 point

-

1 point

-

Default is to use 15% bridging of the insulation in timber frame - manufacturers will take this into account in their U-values. 90mm Celotex in the above wall will achieve approx 0.35 W/m2K. adding a further layer of say 25mm internally would drop this to approx 0.24 W/m2K1 point

-

the kingspan/celotex/any other manufacturers calculations all account for the amount of timber in the wall construction, the uvalues are area weighted, you don't do different calcs for each bit of the wall1 point

-

I agree with all the above, the mantra here is insulation insulation insulation, fabric first approach, you only buy insulation once, all other things either have a life or need constant spend (electricity etc). My build is not to Passive spec but passive esc, in other words loads of insulation and attention to detail re airtightness. I have a small 5kW ASHP and MVHR, both bought through EBay and self installed, not rocket science. I too have UFH downstairs and only towel rads and electric UFH In bathrooms, no heating at all in bedrooms as the whole house is a constant temp. re question 9, like others here with an ASHP I only heat DHW to 48’, most gas boilers are 60’ ish the standing losses from a hot water tank are much less when stored at this temp, it’s also too hot to hold your hand under (washing up) and bath /showers more than hot enough BUT, you will blend down the water less so the DHW tank needs to be larger.1 point

-

The risk of insurance being invalid, to me would be main reason most will install.1 point

-

what calculator are using for those values? Kingspan calc gives a lot better on those thicknesses https://www.uvalue-calculator.co.uk/calculator/walls/timber frame/insulation between timber studs with (insulated) plasterboard/140mm/timber cladding/37.5/80/1 point

-

Here is what I did. I don't have and don't want a smart meter. I just have the standard dumb single rate meter. I then added my own export meter. It is the same meter sold as a generation meter for solar PV. But notice the mains from the suppliers meter goes to the "output" terminals of this meter, and the "input" terminals connect through the meter box No 2 and my distribution to the house and other places. So this meter records what is exported back to the grid and does not register what is imported. I read all my meters once a week and log energy usage.1 point

-

I think he means Octopus can draw from the battery and cycle it as they see fit. every time I press the wipers to clean the screen an image is sent back to base so they can use AI to adjust the algorithm to make the software work better. I love it! my car just keeps getting better over time.1 point

-

That spec looks like a poor loft conversion in the 90,s, it will be cold. Unless some serious internal insulation is done as well as good air sealing.1 point

-

My other place was boarded with sheets that went from wall to wall no butt joins so a 4.7m long wall had a 4.8m sheet used, fitted across the wall so one tapered join at 1200 high. I used boards on my ceiling that where 1200x 6000 England is just not set up for this style of boarding. I think i had 3 butt joins in the whole house, you can buy a butt joining strip in America, it is a piece of OSB that you screw on a butt join, it is tapered so it bends the board inwards to allow jointing compound to fit in the recess.1 point

-

1 point

-

We had a quote with the Panasonic R32 which was cheaper that the R290 Vaillant aroTHERM plus. I've not checked the quoted noise levels, but the Vaillants do not seem to be the quietest out there.1 point

-

assuming they get past the automatic defence systems that is (powered by my Powerwall 2 of course)1 point

-

1 point

-

I've always thought that for a given wall or ceiling board, a skim adds 3.5mm to 5mm of gypsum increasing both sound deadening and I would also think fire performance. Becuase this site applied finish can't be quality controlled by the manufacturer, I'm assuming they dont give performance data (or maybe they dont give data becasue my idea is nonsense ? ). But I would think side-by-side, a 12.5mm boarded partition wall with a skim either side would have approx 8mm or more gypsum than the same taped and jointed and would perform better in terms of both sound transmission and fire resistance. This is just my own speculaton, I have no data to prove it ? Skimming is a more durable finish IMO but the aesthetics of skim or taping will depend on availability of skilled trades to perform either. Having watched an office fitting crew at work some years ago, I saw that taping and jointing to a high standard was skilled work, they were fast but very attentive to detail and once painted you couldn't so much as see a joint or seam. I suspect that DIY would result in a lot of sanding and it may be very time consuming. Ofcourse another consideration is that skimming is not really something most folk would try DIY (give it a go, it's fun, but don't wear your best shoes). I did a plastering course many years ago as had heaps of plastering to do in a renovation and it was our first house (and we couldnt afford a plasterer). I can skim pretty well now but cant cover anyhting like the area a pro would cover in a day so I'm using a local plasterer on my renovation and extension/loft conversion this time around, with me doing the odd bit as needed. possibly relevent to the original post, if wet plastering solid walls then a basecoat is needed. this is a different feather in the plasterer's cap and some plasterers don't do it much now as on large sites it is always dot and dabbed boards (to hide the cracks that form in the blockwork and becuase it is fast) so the art of floating and setting a wall is slowly being lost. The postive to float and set is making the wall air tight with a nice coat of backing plaster and not creating an air space for convection and draughts behind dabbed boards where air leaks through the mortar joints or cracks in the external wall. Peronsally I wouldn't dot and dab ever, and definitely would not on on external walls of a period house. Dot and dabbed walls are also a pain to fix things into. Float and set is an art to get a decent flat finish in the basecoat, especially over a rough or variable background like old brickwork. The block or bricks also need copious priming with a dilute PVA to kill the suction and avoid the plaster drying too fast. It's then two coat skimmed to a finish. DIY approach to float and set is to set battens on the wall of suitable thickness (about 12mm) to create 600mm wide bays and fill with basecoat and rule off against battens with a feather edge, the take battens down and fill the batten voids, works well but is again time consuming and pro would smile watching you spend all morning doing something that would have taken them 20minutes.1 point

-

I watched that fully charged YouTube vid (assuming we're talking about the same one where Kryten get's his PW2 installed) and he did go on to state that the change over should've been a lot quicker than that. I will have a UPS for my mission critical stuff and things with HDDs so as to protect them. And don't forget that when the zombie apocalypse arrives and the main grid goes down myself and @pocster will be the ones with electricity still running while everyone else is cowering in the dark. ps. don't know the answer to the EPS single circuit or whole house. electrics baffle me.1 point

-

We have an insert pellet stove however originally it was to be a double sided wood burning stove, we have no chimney so a false wall was built using the attached product , this went right up to the ceiling (cathedral) with the flue inside then the black flue out through the roof, we then tiled the false chimney breast1 point

-

your main problem is the low angle --most recommend 14degree as minimum --you have 5 degrees Me --i would dump it and convert to GRP reusing corroded sheets ,then new plywood +fancy expensive membrane -- -- does not sound a good idea -and you still have an inherent problem of low angle- which no marker will warranty their product for If its looks your after--then maybe convert to GRP and refit your alluminium on top1 point

-

the uvalue calcs take account of the amount of timber in the wall construction - with 100mm kit you'll definitely need some insulation on the inside too rather than just between studs1 point

-

We doubled up on the BT duct, to allow for future cable/fiber internet. Sometimes these companies don't like sharing ducts. Can't you simply take two ducts out; one to garden and one to front gate and then do all external wiring seperatly later? External lights attached to house is a bit different though. We hadn't planned for this at all, but are now hurriedly trying to work this out before everything gets rendered. Uplighters wired in as part of lanscaping is one option, but if you want fittings on the facade itself these need pentrations into house or conduits behind renderboard/finnish. I'd suggest finalizing your plant room layout if at all possible before defining exact duct positions as otherwise duct locations may dictate where things need to go Don't forget condensate from MVHR, waste water from water softener etc. You'll either need to wire back to a relay/dimmer, or use lights along with a control system (e.g. DALI/DMX or something else). If you don't want to wire everything back to the house then you'll need to either have relay/dimmers outside the house.. or use a control bus. Don't you have anywhere in the house, that is outside the thermal envolope where you are left concerned about penetrations, that you could wire everything too? Or better still some sort of strategic location outside of the house e.g. future location of garage? Thats what we did, yes. Only other reason for ducts between rooms, other that islands, is if you want a in-floor power sockets anywhere.1 point

-

Ask if you can record it or take someone else with you to take notes. You can’t record without permission though - don’t be tempted to do it covertly as it will undermine all your hard work. Make it clear to them that you are not accepting anything in the meeting and will need any offers in writing before you decide anything. And good luck ..!1 point

-

Normally jam an off cut of 3x2 leaving a 50 mill gap If you butt it up tight You May have trouble plumbing the truss1 point

-

Sounds like a really small amount of insulation. Also what you are describing sounds like a hybrid roof construction and may be prone to interstitial condensation1 point

-

Yes, if SW Suffolk counts as SE. We put the ufh pipes and manifolds in, and the reinforcing mesh. Had a company in to do the pour, approx 200m2 done in 2 days. Separate company did the polishing. It's not perfect by any means, but as a barn conversion rather than high end loft, it's good enough for us. Splitting the job up meant any risks sat with us, but that meant cost savings, and was cheaper than other floor covering options, plus it's what we wanted, ie no carpet, few grout lines.1 point

This leaderboard is set to London/GMT+01:00