Leaderboard

Popular Content

Showing content with the highest reputation on 07/23/20 in all areas

-

Under 20 bars of scaffold would be cheap, £50 to a local scaffolding company . 5 mins to put in place and take away. Can be stored in a fairly narrow gap. The frame is much more important than a fancy winch. It's what will take the weight.2 points

-

Can’t see why 28mm has been specified - the Nibe needs 0.29l/s minimum flow on defrost which is just over a cubic metre per hour. On 36m of pipe at that flow rate the head loss is 21.6KPa so a circulation pump would need to run at approx 3.2m head on 22mm pipe . That’s well within the capability of a 6m circulation pump. In standard heating mode it is 2.52KPa (0.11 l/s) I checked the difference with 28mm copper vs Hep2O and it’s about 0.01kpa/m which is pretty negligible using Lamont’s2 points

-

On a hot summer day the MVHR will reduce the heat gain. It does this by switching on the heat recovery, in effect coolth recovery. This will not work if you open all windows and doors, though. You can open windows at night to cool the house then shut tight mid morning to preserve the cool. I understand that the air flow in the MVHR is too low to support substantial cooling, though it should work to some degree. In either of the above you will get maximum benefit if you continue to pay attention to air tightness and insulation.1 point

-

Definitely fit MVHR in a well sealed well insulated new build. I assume in your present house you have trickle vents on all the windows but are still finding it a bit stuffy? MVHR will ensure you have constant fresh air inside the house but without wasting heat. It's such a simple and reliable thing there is no reason not to fit it. Exactly what put your wife off it? You can get mvhr units with a small air to air heat pump built in that will do a small amount of cooling (and heating)1 point

-

In a nutshell.......no. MVHR has two modes, if generic; 1) heat recovery 2) summer bypass ( so no heat recovery ) If you want cooling then you need an ASHP that you can reverse, and cooling batteries ( basically a fan coil ) that will allow the air to the supply valves to be sent through what is essentially a car radiator in a box which has cooled water flowing through it. Above that, you will need air con. Depends upon if you're 3 storey or 2 story, and how you sleep at night in a slightly hotter house than you'd like.1 point

-

There's a BRE guide for rainwater soakaways it's all slightly different inputs and the output is in m3 too rather than m2 for a drainage field... Scottish building regs have a simplified calc too that you can use on a single dwelling...1 point

-

1 point

-

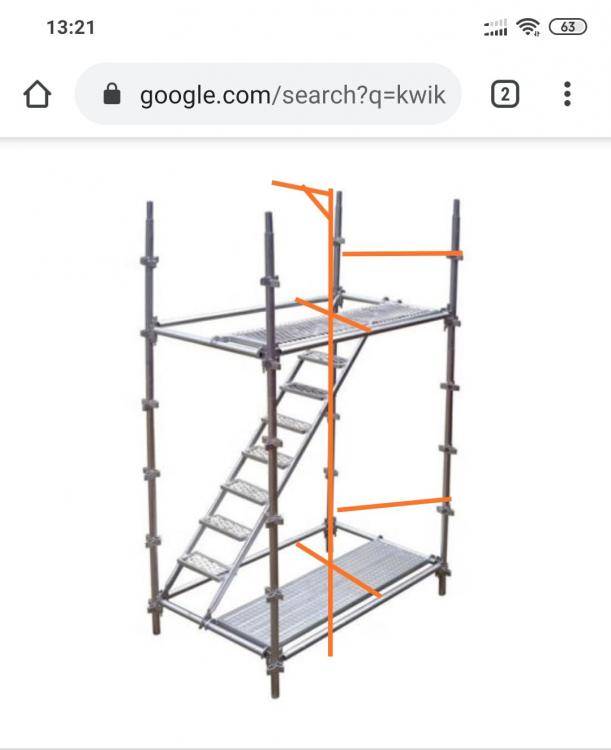

I put up a kwikstage frame to lift both my 4.2m concrete lintels. Used a pulley block and sling attached to a standard across the top ledgers. It was easy 200kg+ in weight and the frame took it easily. You could easily use the same but connect the electric winch onto the top. Have planks across the gap and you can set your cage on them and load it with whatever is going down. Start the lift and remove the planks and lower it down. With the winch on the inside of the frame it won't tip over as all the weight is in the middle. You have diagonal bars to each corner to strengthen it all up.1 point

-

There are plenty of two and three zone controllers out there that can switch 10A per channel, and a simple thermostat in each circuit gives time and temperature control to the UFH. Using the stat on the buffer means that you can also negate the UFH/ASHP interlock and put the buffer in the driving seat and reduce short cycling as the tank stat will smooth out the demands as the zone actuators open up and close down. I’ll see if I’ve got the control circuit drawn up for mine - it uses W Plan wiring with a modification to allow the pump to be run without heating the floor (if I enabled cooling for example)1 point

-

IoT stands for Introduction of Trouble in my book - I’ve still yet to find the person that needs to be able to change their bathroom UFH setting whilst sat at a Starbucks with a soya latte .... UFH is far from real time feedback, and response time is measured in hours usually so I think the “connected” stats are a solution looking for a problem rather than anything of real world benefit. There is a significant benefit for using off the shelf components where they need to be used by more than one person unless you plan to write a controls manual for the house and give everyone a copy who walks through the door.1 point

-

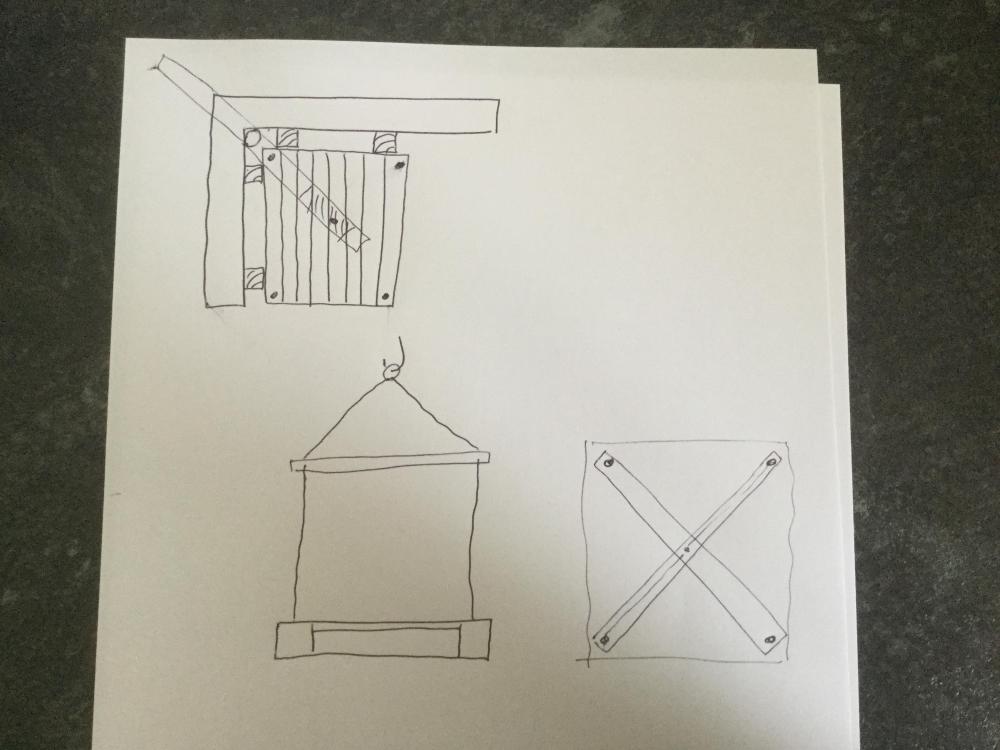

no, being in the corner rubbing up timber verticals it cannot twist, any weight on the platform will keep it against the wall. The advantage of using scaffold clamps mean you can adjust any joints rather than drilling etc.1 point

-

?, now I am only 9 stone but I would certainly ride that ?. There are lots that wouldn’t tho ?. Just had another thought, if that horizontal pole extended over the “platform” (pallet) a little, a long bolt in the end could locate in a hole in the platform to stop it swinging away from the wall when loading it!!! The winding mechanism has an “auto stop” to stop you winding the hook into the motor, you could rig it so this coIncides with the platform being level with the ground. (am I on commission???)1 point

-

Why not just erect a quick build steel tower and use that as your "lift shaft"? Strap to the walls rather than use outriggers. Your're so off piste with this in terms of H&S and probablyy LOLER and PUWER if you have any trades using it. https://www.toptower.co.uk/classic-scaffold-tower.html?gclid=EAIaIQobChMIqpuo55zj6gIVVeDtCh0Odw8KEAYYAyABEgJgffD_BwE1 point

-

1 point

-

Altro Whiterock or a similar. Sheeting is about 3mm thick. With the right kit it can be bent to form around corners. It is glued on. https://www.altro.co.uk/Altro-Whiterock-White a bit institutional but easy to clean.1 point

-

Probably best but because they are in compression timber might do. I can just imagine what an SE or health and safety bod would say (but would not stop me doing it!!!,,, swivel clamps like these (swivel clamps allow you to clamp poles that are not at 90’ to each other) https://www.ebay.co.uk/itm/15-x-Scaffolding-Scaffold-Fittings-SWIVEL-DOUBLE-Couplers-Clamps-FREE-DELIVERY/224085486430?hash=item342c892b5e:g:w2cAAOSwKG1fCHBR shame I am so far away, I would love to help build this. Just make sure no building inspectors see it as they will have a fit1 point

-

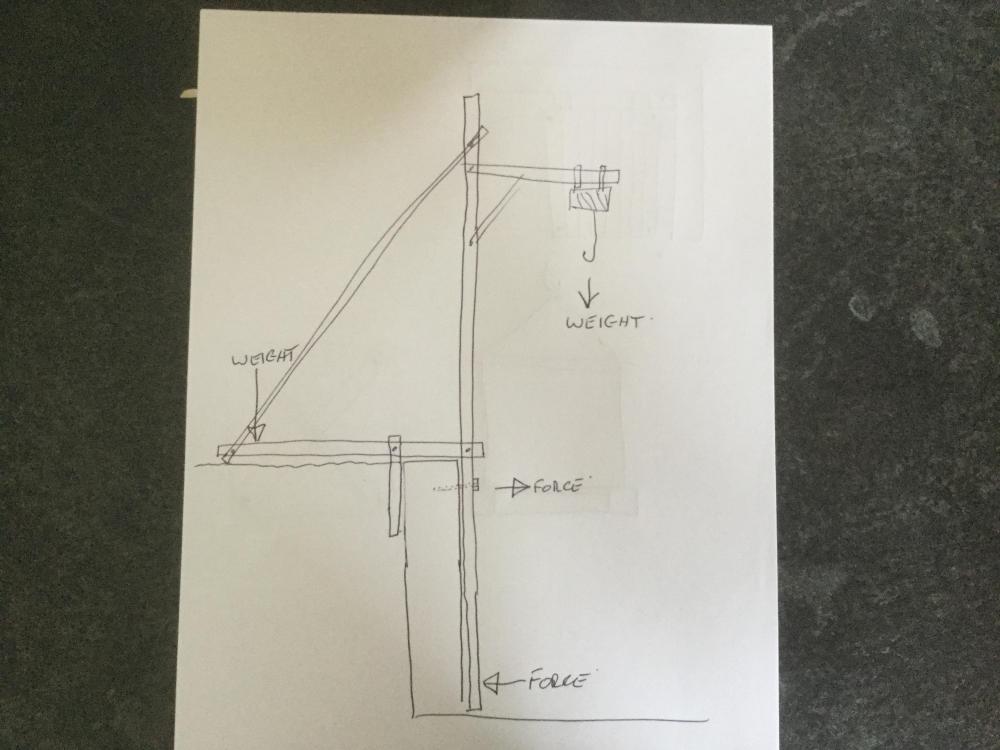

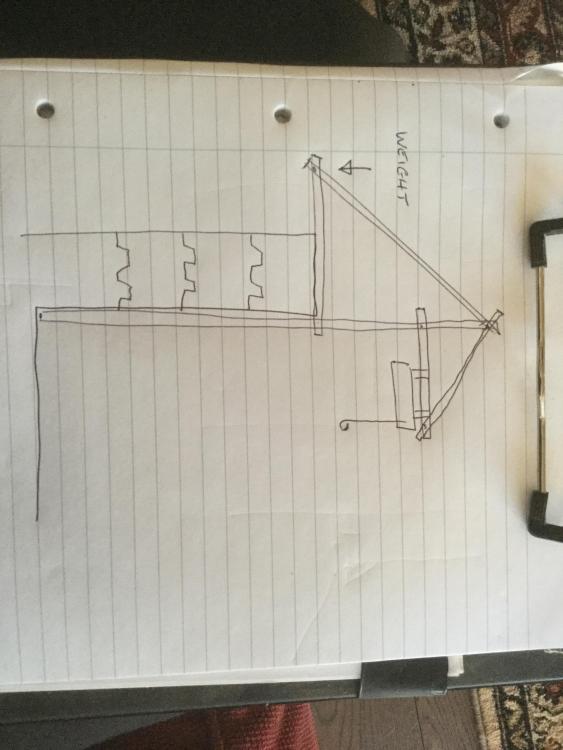

WTF!!!! I don’t see why you need 4 vertical poles, one up the corner bolted to the wall (mostly at the top). Triangulated gubbins at the top like I said before, 4” square timbers up both walls to guide the sides of the pallet (and keep it away from the pole). See crap drawing below regarding spreader bars. Perhaps a scaffold clamp in the corner to stop the platform swinging whilst loading it.1 point

-

Just remember with corner slings that the load gets exponentially multiplied as the angle gets flatter. So if you go that route your hoist will need to be a good bit higher than the top of the cage/spreader frame to allow for a decent angle on the slings - 60 degrees is common. That will obviously then mean a longer pole sticking up, so more bracing to counteract the greater forces where it meets the wall. If you can instead do an up and over stirrup so you can put the hoist on a single point above the centre that would allow you to minimise the hoist height. But obviously creates more of a risk of tipping.1 point

-

1 point

-

1 point

-

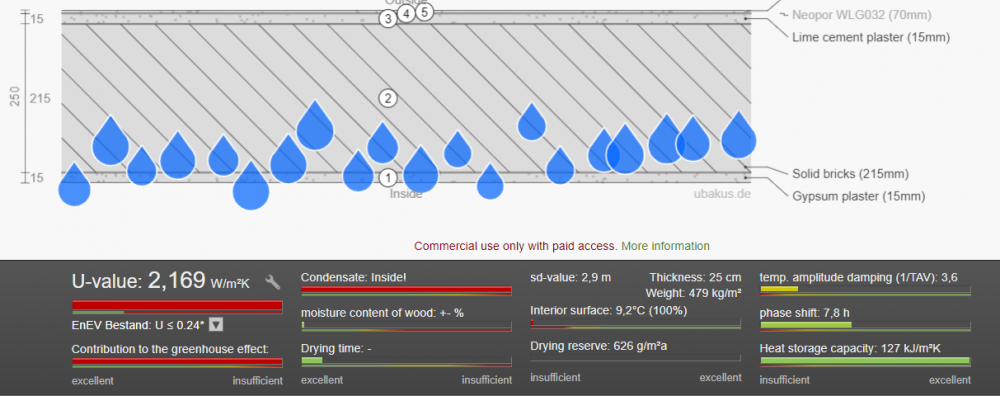

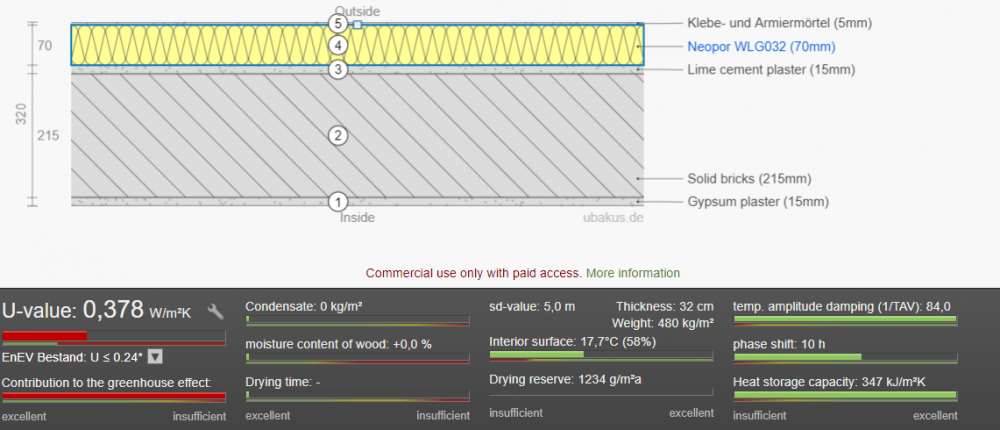

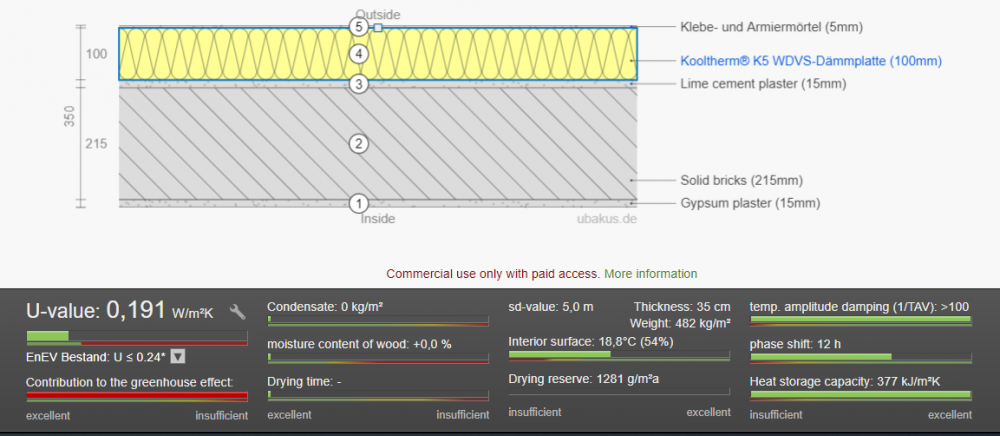

Majority of people use Graphite EPS, for cost vs performance. 70mm will get you to 0.38U, however bear in mind that at the minute you are probably around 2.2U, rather than 1.8U you suggested, thats still a massive improvement. You can go over the amount you have available in your soffits, but in my opinion this is when it starts looking horrible. Before After with 70mm EPS After with 100mm Kingspan K5 Phenolic Hope it helps in making your decision. Regards Mike1 point

-

Go for it. What do I know after 40 years working in the access game? ? Anti spin ropes are shite too btw. Strategically placed wall rollers can help with preventing spinning. You DO NOT want this thing catching as you hoist up. It'll overload the lifting jib unless you guard against it. Similarly, snagging on the way down is bad, they can snag, pay out rope then suddenly drop. All sorts of considerations.1 point

-

Have a scout round temporary access yards for a "one man cradle" maybe. Even a Solsit (powered chair) would have all the gubbins to adapt; 230V winch, secondary safety device etc. Then "all" you need to worry about is the jib up top! ? A platform on a single suspension point may have a tendency to spin. I'd be looking at guide rails...like a lift. https://www.tractel.com/en/product/solo-platform-for-temporary-access/14156?pimcore_request_source=staticroute&controller=Product&action=default1 point

-

Hi Hughes. This is a post in two halves. This is for Hughes. and.. As this is a self build type hub the following is partly a general thing for folk that are at the beginning of a journey. Hughes, sounds to me that you are nearly there.. maybe you just need a bit of encouragement. If you take care, measure twice and so on.. it's all doable. For all.. If you're thinking about a self build or DIY project then if you can find something smallish to practice with you are off to a good start. It may just be using your hands, get a feel for basic tools, (a spirit level, tape and so on) the names for other common tools, materials (bricks, blocks) and the language that is used on sites like this. You may want to be less "hands on" but the same rules apply. Hughes, your post struck me. I remember someone from Motorola sales explaining to me about the FUD factor ..fear, uncertainty and doubt. I think it's still relevant to a lot of people; how we fear stepping into the unknown, you know there are uncertainties, then you doubt you own ability. What if you put in the work you need to do, take professional advice if need be at the right time, trust in your own judgement, march on and reap the rewards. All the best1 point

-

If setting fire to a live cow is your idea of BBQ, remind me never to come round for dinner1 point

-

1 point

-

Yes. As @PeterW has suggested, fix the wall plate to the steel - then fix the joists to the wall plate.1 point

-

1 point

-

1 point

-

I missed that "instruction" I have all XL Joinery Oak doors fitted to my plastered new build without issue. It is probably a case of my build is slow and by the time I even bought the doors it was many many months after the house was plastered and painted and dried out so there were no issues. I suspect what they want to avoid is the plasterer coming on Monday, the painter on Wednesday and the doors being hung on Friday in a mass produced rushed new build.1 point

-

1 point

-

1 point

-

I know this is an old post, but we suffered from this and in the exact same circumstances. It got better year on year and after about 3-4 seasons, was OK, the grass had become strong enough to survive up to the edges.1 point

-

1 point

-

That does seem very high. I take it that price doesn't include the warranty. I don't know, but I guess it could be that conversions are more expensive than new builds as the underlying asset of the existing house is at risk. Do shop around as prices vary hugely. SelfBuildZone are another provider to try if you haven't already.1 point

-

We used Protec less than 2 k We only used the basic package Insure us against someone wandering on and injuring themselves Fire damage to the house Once you start adding liability for contractors or tool and plant insurance The price almost doubled1 point

-

0 points

-

0 points

-

From my experience using scaffold as a hoist I think one pole (suitably triangulated above ground) will be well able to cope with 100kg, if you load the counter weight matching platform loading . Running up a corner (on suitable vertical timbers) the platform cannot twist. If the platform is located on a bolt as suggested at the top it cannot swing during loading. stop procrastinating and get on with it ??????????0 points

-

0 points

-

0 points

-

Then why not a winch like I suggested, a strong pallet with a wire from each corner, spreader bars to keep the wires vertical, if the pallet is in the corner it cannot twist, maybe a couple of timbers up the wall as guide rails, don’t let health and safety see it but I think I would suit your needs without £££££ and loads of work? ?0 points

This leaderboard is set to London/GMT+01:00