Leaderboard

Popular Content

Showing content with the highest reputation on 03/26/20 in all areas

-

2 points

-

The wailing and gnashing of teeth when my digga left the premises only got worse when I realised that Hartley Hire (good mates to me) were shutting up shop - no diggas for hire. The BH member who stole my beloved digger - you know who you are, (Sue) - should give it me back: pronto. I didn't mean to sell it. It wuz an accident. Honest.? I need to dig the trenches for our foul drains. But no digger. Or prospect of a digger. Just a day's work with a 2 tonner. Poo. Back t' 'drawin' board then. Dad was one of the Bridge Masters who were employed by the Local Authority while the M5 was being built. He was permanently banging on about coffer dams. Very focused on digging deep holes for bridge paprapets. Dimly, I seemed to remember something about digging deep holes in sand - like they have to do everywhere in Berlin. Its tricky, dangerous work. I recon the invert for our foul drain is about 1300mm down: not that far. But far enough if the bloody trench keeps falling in. I don't mind spade work, but a weekends' work was disappearing before my eyes. Damn. And then I remembered the key term: timber shoring, or even close timber shoring . Quick google and then this You beauty. Here's the trench without shoring Can't photograph a sore back: but it's sore. Monday afternoon I notice the edge is starting to cave in - collapse. So this is what did .... I've yet to dig towards the house (as opposed to along the side): thats where I'll need the close timber shoring. I'll post some pics tomorrow. Yes, I have blisters on my hands. Big girl......1 point

-

Some council's have published guidelines and they contradict each other.. http://www.spelthorne.gov.uk/media/15694/How-GIA-is-measured/pdf/Definition_of_Community_Infrastructure_Levy_GIA.pdf Includes garages, car ports, fuel stores, conservatories, cleaners cupboads. Excludes sheds, greenhouses, solar panels. https://www.stroud.gov.uk/media/241065/calculation-guidance.pdf Includes greenhouses and similar buildings (if a person can go in), indoor swimming pools. Has a different rule for car ports (depends how many walls). Excludes Outdoor pools.1 point

-

https://www.drainagesuperstore.co.uk/product/110mm-1125-degree-single-solvent-weld-socket-bottom-offset-bend.html1 point

-

1 point

-

Look for 112.5 (22.5) In reality I wouldn’t have done it like that and having soil pipes do a 90 degree tee is not ideal. I would have used a Y junction further down the flow, and then used a standard swept elbow at the bottom of the vertical to direct it across at 45 degrees to the main flow. I would also be securing the horizontal flow much better as a vertical drop will bounce that joint hard and you need to strap it tight up against the elbow.1 point

-

1 point

-

Part H https://www.planningportal.co.uk/info/200135/approved_documents/71/part_h_-_drainage_and_waste_disposal Min 200mm from memory but I would check. Also worth trying to get a strap boss in the top half of a horizontal run1 point

-

1 point

-

Ok so @Jilly if you are saying you are putting a floating floor over the insulation which sits on the 150mm concrete then you have an issue. You’ll need to use min 90mm PIR and then float a 22mm chipboard floor that is then fitted with your final floor finish. That assumes that the current floor is dead flat, and if not you will need to use levelling compound on the slab to start with. You don’t need a liquid DPM - you can put that on top of the insulation and below the chipboard and use standard DPM with the excess taped up the walls.1 point

-

Not really. Most is done using 10mm pipe these days so that’s not a very thick bed.1 point

-

TBH I have a Festool Plunge saw and 4m of rail which I can put together in various lengths (Think the whole kit was about £1K) and yet I almost exclusively use my little Dwalt battery saw up against a 2.5m length of 8x50 aluminum bar. It is dead quick and I can get the accuracy I crave. You need thin bar to get under the motor overhang, I marked the saw with the distances from blade edge to base edge both ways to make set up dead easy as well and drilled and countersunk holes in the bar to allow me to clamp it to the board. Total cost about £150 - much better.1 point

-

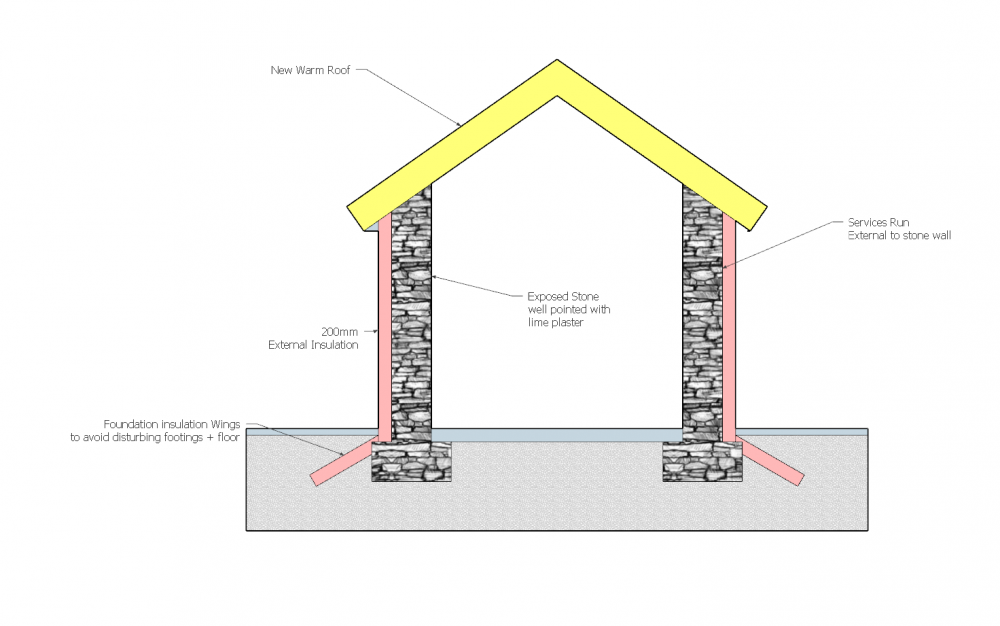

Hi Geoffrey, How thick are the walls? I had a quick peruse of this paper. https://www.historicenvironment.scot/archives-and-research/publications/publication/?publicationId=16d0f7f7-44c4-4670-a96b-a59400bcdc91 They measured old stone and rubble walls in situ . I didn't read too deeply but it suggests a conductivity of about 0.72 W/mK although they varied to about double this ( I suspect for walls with higher levels of dampness). If you were confident your walls could be kept dry and were say 600mm thick could you expect a U value of 1.2W/m2 K. Well short of the regs but maybe with very high levels of floor and roof insulation, good air-tightness and triple glazed windows you could create a very comfortable home with your exposed stone walls. Failing that, externally insulating would work nicely and allow you to run all your services from the outside-in avoiding conduit or pipes showing inside. If there was no proper footings, insulation wings as shown joining to the external insulation would do the trick. Jonathan1 point

-

A lesson from this thread for the novice might be forget solvent weld and use push fit where you can. No time limit, plenty of time to do each joint one at a time, and if you have a space issue, a slip coupling is your friend.1 point

-

I've had that done quite successfully on a project - it's quite fiddly tho. Have you thought about heating pipes in the skirting boards? https://www.discreteheat.com/lp/thermaskirt-skirting-heating/?AdSource=0110&AdMatchType=&AdKeyword=&AdDevice=c&gclid=CjwKCAjwguzzBRBiEiwAgU0FTwI5czGlriAKrunoW5BDL98dy7rCUGg76o3FV4umkCPuUDEf-_xZxhoCwgIQAvD_BwE I've not used it but it might be worth a look? As always make sure the house is really well insulated and as airtight as you can (ventilation managed etc) first. so that you need as little heat as possible.1 point

-

what idid was to fix battons to sides of floor joist then infill with pur -clip pipes to that so they were hard up against the 22mm osb flooring-proud by 5mm before floor laid ---been working fine for 15years,just make sure you blank off the ends of the joist so heat cannot esacape somewhere else. not saying best way --its what i did and it works fine1 point

-

0 points

-

step away from the flexi... 90 degree elbow on the horizontal then use an 11/22 degree single socket to align to the bottom pipe. Hope you can lift that vertical pipe though ....0 points

This leaderboard is set to London/GMT+01:00