Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/20 in all areas

-

2 points

-

If it was me I would want to know exactly how much I was going spend on piles which means getting a proper site investigation done. Once you have this then you might think no it's going to cost to much or yep that's a good price and proceed. @Bitpipe the wacking of the rods is called dynamic probing and will give an indication of the bearing strength of the ground. You measure out 100mm sections and count how many blows it takes to drive the rod that depth. The more blows the better. But as it's just a beating session there is no way of knowing what is actually down there so that's why they take the cores.2 points

-

Straight couplers, for joining two lengths of soil pipe, come in two flavours. The normal one has internal stops to allow the pipe to be inserted and then be restrained from further penetration. The snag with this is that sometimes you have a constraint that stops you moving the two bits of pipe to be joined far enough apart to be able to fit the coupler. A slip coupler has no internal stops, so can be slid completely on to one pipe, the pipes positioned so they are virtually touching each other, and then the coupler slipped back so that it's centred over the joint. Slip couplers are less foolproof to use, as they need to be positioned in exactly the right place over the joint, but are very useful at times.2 points

-

Hello all, it's been a while (3 years!) since I signed up and posted on here but I've come back to ask for opinions/experience as this is where I first became aware of SunAmps in any great detail thanks to JSHarris and others. We had a UniQ 3 and UniQ 6 fitted in December 2018 (full disclosure - it happened, by chance, to be by NickfromWales - hi Nick- but we ordered direct from SunAmp). After some initial grumbles which I wont go into in this post, we now have a fairly decent setup with an Eddi managing the PV diversion between each unit - 6kWh sitting in our Utility and 3kWh in the En-suite. This year we finally got our shower installed and have started using the smaller unit much more frequently. As a result (and the lack of sunshine thanks to Storms X,Y & Z...) we're now in the habit of boosting the unit at 3am each night so that it should be full the next day. This week we had a good sunny day where we made 9kWh (according to the solar edge inverter). Our Eddi recorded that all of this power was diverted into the smaller unit, despite the fact that this is basically double the capacity of the battery. What's more, that evening we noticed the Eddi indicator wasn't showing the tank as full and we ended up having to boost it for a further hour (i.e. practically a full charge). My question is simply, where is this power going? I can't believe the UniQ is physically losing that much heat, even if the insulation has bowed a bit (I know that's a thing). So are the UniQ's designed to discharge any excess straight back into the grid? Or is this just that a sensor has become uncalibrated (I'm aware the Eddi is relying on a CT clamp). Any ideas? I'm hoping it's not something more serious with the controller units etc. as it's been a long journey to get here.1 point

-

Hi all, We are considering external timber cladding, shiplap style. It will be painted black, like this: I would like class 1 or 2 (Very Durable or Durable), but that mostly means things like good quality Oak. My reservation about using something like Oak is that the cost seems to reflect the way the wood will age well and go silver over time, which of course is irrelevant to me if I'm painting it black anyway. Does anyone have any suggestions for less expensive durable shiplap I can paint? Building regulations regarding fire risks are not relevant by the way as the walls in question will not face boundaries. Thanks1 point

-

The regulations on socket and switch heights refer to "general purpose" sockets. You can have a dedicated function socket at any height you like, e.g. the high up one for the tv.1 point

-

Get building control to have a look and document anything they are not happy with and pass that to the builder.1 point

-

I would just get a solicitors letter and countersue, in the sense of saying we will not pay up and we will be looking for damages to cover all the remedial work, the cost of an investigation by a competent person into the quality and any delay costs incurred by you. Also you will be writing to all the trade bodies, they are members of, with photographs of the work and a copy of the investigation. See if that gets them back to the table. Never let a bully win.1 point

-

Of all my various makes I have lying around this stuff seemed the most “stable” in regards to shrinking and warping, I think it’s made in Ireland? Maybe I got that wrong but someone on here has used it for a house build. https://www.xtratherm.com/products/xt-tf/ but as Peter says maybe it all comes from the same place with different labels on it !!!!!!!! ..... surely not if I was buying it I would not bother with calotex again as this seems the worst for warping and shrinking in my experience. Others have not had problems with calotex but I guess they don’t have it sitting around in there sheds for 5+ years.........1 point

-

Not sure, TBH. Last time I used fart mode I selected Ludicrous Mode and set it to fart on turn signal, with the default seat position for farts to be the front passenger seat. SWMBO was not amused when I indicated to pull out of our lane . . .1 point

-

I had Sieger Slim® sliding door system - 20mm wide profile 5700mm wide x 2350mm high -Two track Sieger® XL sliding door system comprising of 2nr sliding panes (→←). Triple Glazed 1540mm wide x 2050mm high - Two track Sieger® Slim sliding door system comprising of 1nr sliding and 1nr fixed panes (F,←) 1540mm wide x 2050mm high - Schuco aluminium framed casement single door with fixed / top hung side light Casement Windows 420mm wide x 950mm high - Sieger aluminium framed casement window arrangement comprising 1nr fixed pane with top hung pane above including standard ironmongery 1550mm wide x 1400mm high - Sieger aluminium framed 2nr side hung casement windows with fixed glass inbetween1 point

-

Q2, yes, the trap screws in to the waste. The trap will be telescopic so you can get the fall right then tighten the compression ring on the bottle. Don't lube as trap will just fall down over time. Btw, you need to make sure the overflow slot on the waste lines up with the slot in your sink. Took me three attempts to get one deep enough to match the slot in my sink. I would have thought it would be standard dimension but obviously not. This is how ours ended up. Chrome pipe in to compression coupler, can't remember the rest!1 point

-

So the 45 degree rule would indicate that the load is spread and a vehicle would have to be very close to the building to exert a load that would move a block with 12-15 more rows of blocks sat on top of it. Can see a reason for doing it at a garage doorway but not anywhere else.1 point

-

Yes. And yes, it was bang on for each pile. Except one ? ( refusal required about 200Kn.) The last one. You couldn't make it up.1 point

-

Q1, yes, just a simple 32mm compression fitting. Do NOT lube up the compression side that goes onto the chrome tail. That needs to be dry fit to get the rubber to ‘grab’ the chrome surface. Q2, dunno. ? Suck it and see, but the trap should just screw straight on.1 point

-

1 point

-

Our SE recommended 2m deep trench foundation and we've had no problems. House a few doors down was recommended 3m deep trench foundation by different SE. As a result they got estimates for piling which were slightly cheaper. Problem is when they started piling they found they had to go much deeper than expected and it ended up costing quite a bit more. Don't think it occured to them to do a trial hole.1 point

-

For our basement we had an initial survey which comprised 5-610m probes (steel rods hammered into ground by a rig, penetration for each 'whack' measured) and a few cores (soil composition, gas & water monitoring). Results were inconclusive and suggested piling may be necessary due to historical near 'made ground' i.e. filled in gravel pit. We paid for a more intensive follow up survey (10-12 probes, 5-6 cores) and got better data that suggested that piling not required. While it pained me to pay the extra £2k (discounted as they made a few errors in the first survey) I was happy we had solid data to move forward with. Up to you ultimately, you could crack on and see what happens but at that stage you're committed (if you can find a firm to do it without strong data).1 point

-

Depends on the piling method I guess. Our mobilisation cost was £1200.1 point

-

Hmmm, @Andrew.... our piling company wouldn't come on site without a proper site geotech. survey and two trial pits. Reason? Risk reduction. To get a 45 tonne rig on site is expensive....1 point

-

Our piling company were quite clear we wouldn't know how deep the piles were going until the first one was driven to set (and even then the conditions could change across the site so whilst the others would most likely be in the same ball-park they may differ). The cost of mobilisation and the first pile will most likely be around the price of the geotechnical survey - you can always say stop if the first pile goes down to 30m. I wouldn't waste my money on the survey.1 point

-

I chamfered the bath corner as well as sinking the bath. Also the sides rake inward. Works really well.1 point

-

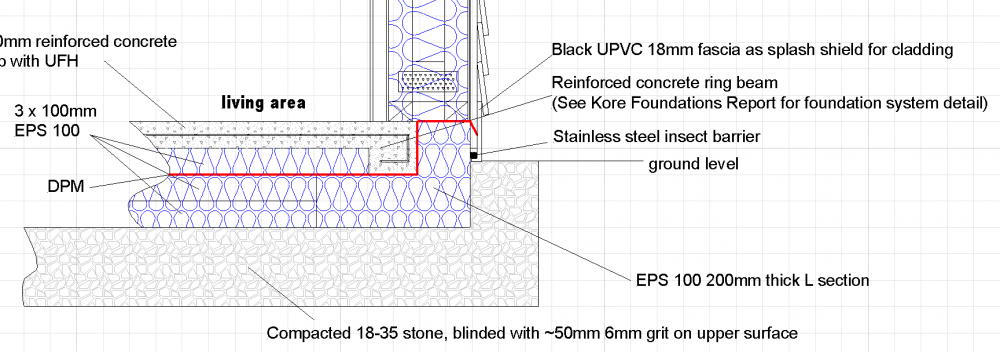

Here's a cross section of the lower part of our external walls that may help: This isn't quite as I did it, as I left the DPM layer where it was, running right down to ground level, rather than trim it. The cladding I used was the widest width of L shaped fascia I could find, I think it was probably this one, or one like it, but in black: https://www.eurocell.co.uk/fascia-boards/replacement-fascia-18mm/250mm-x-18mm-fascia-board-in-white-x-5m As our house is clad with waney edge larch, the 18mm thickness of the uPVC worked OK. I just extended the vertical battens on which the cladding is fixed down to a few inches above ground level, and the L shape of the uPVC partially closed off the ends of them. These battens also held the galvanised mesh in place, that was trapped behind the battens, and helped to keep the DPM flat against the EPS.1 point

-

1 point

-

The first survey is just a general investigation into what's below the ground. A geotechnical investigation will involve a full site investigation using a drilling rig to perform a series of tests at different depths to give you a set of figures from which you can work out the bearing strength of the ground. From this your piling company will be able to say you need X amount of piles to be driven in at least 8/9/10m whatever it will be. They can then work out a more exact quote knowing how many and how deep they need to go.1 point

-

I can't quite tell if it's still too tight a quadrant shower might help. Put some boxes etc to simulate getting around things1 point

-

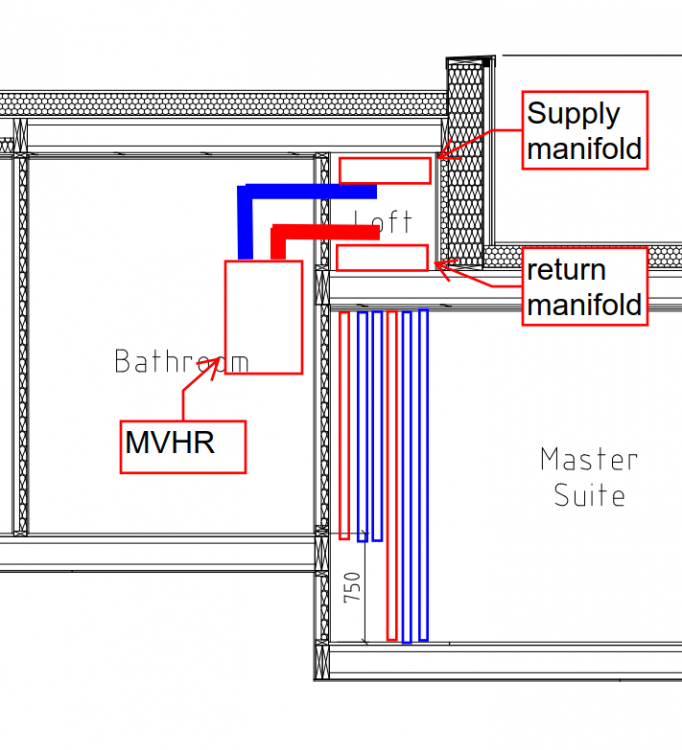

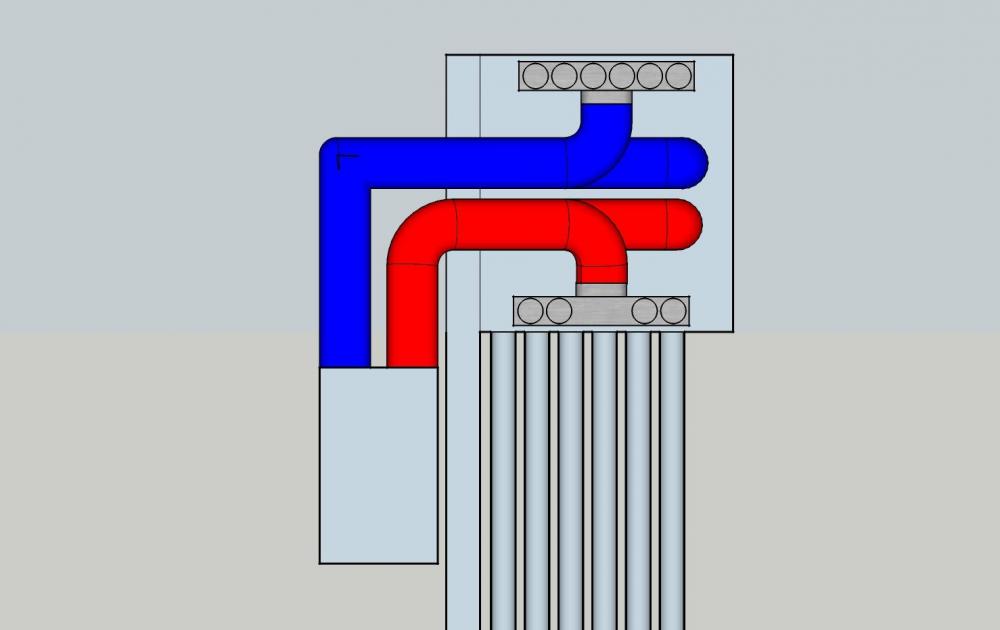

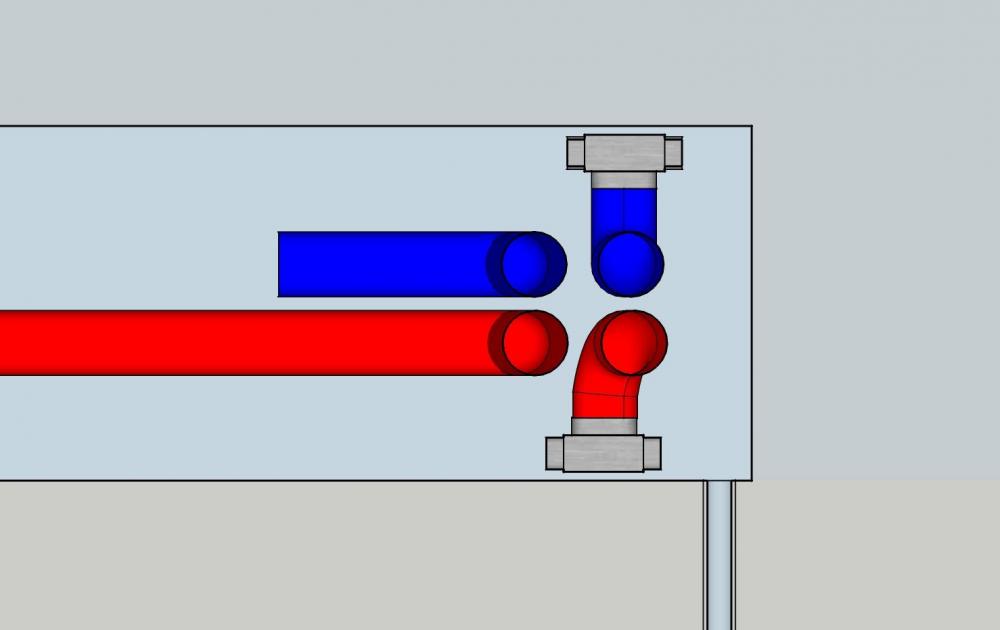

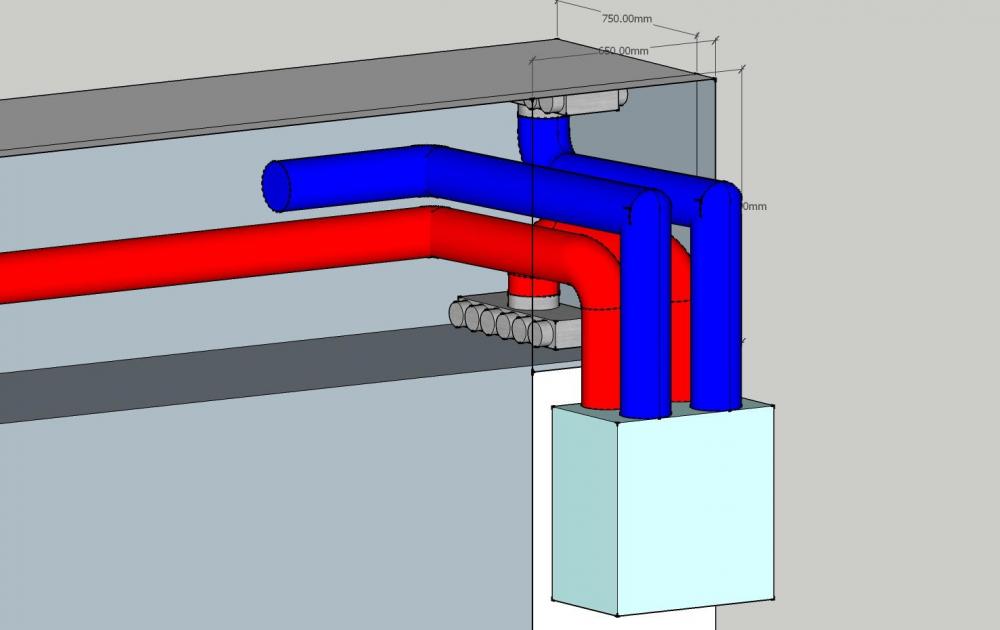

I have been giving this a bit more thought and have sketchup'd the following arrangement in 3D, with the MVHR in the airing cupboard, and ducts running down a riser It seems that it works (Just!), with the return manifold on the floor, and the supply manifold on the the ceiling, as below Section through loft (short section) Long section through loft1 point

-

I left it as was, covered it with galvanised expanded mesh for rodent protection, then fitted black uPVC cladding around the lower part of the house. As a precaution against insects getting in the cavity behind the cladding I used unwound catering size stainless steel pan scourers to close the bottom of the gap up, but I've since discovered that you can buy rolls of stainless steel wool, intended for filling motorcycle silencers, that is easier to use than pan scourers.1 point

-

I think I had a mix - because somethings couldn’t be done in certain ranges . I’ll dig out the spec I had once at home .1 point

-

What he said! Clean clean clean. Also, I like the La-Co flux, it is non acidic so you don't have the old worries of acidic flux being left in joints and eating them over time. It is also handy for longer them work that may not be live for months. https://www.screwfix.com/p/la-co-flux-paste-with-brush-in-cap-125g/61072?kpid=61072&ds_kid=92700048793290397&ds_rl=1249404&gclid=CjwKCAiA7t3yBRADEiwA4GFlI_RF0ft0G1SubltEtdC4mClKiPPV5r8XBbpoTsDn-OX4IFqW8Fea9hoCKzMQAvD_BwE&gclsrc=aw.ds I have dipped stranded wire that had gone near black into this stuff and heated it with a soldering iron and it looked like brand new copper a second or two later! However, steel wool is not actually an accepted method of cleaning under BS EN1254. Plumbers do use it but it was always frowned upon, the issue is if you leave a little steel wire behind it can be included in the solder either fully or partially encapsulated, if the latter then the steel will rust essentially creating a pinhole through the solder, chances are it will be find, but a single strand going through the solder can become a leak fairly quickly (less than a year). The recommended method of cleaning is a wirebrush wheel, or a scotch pad - sand papers and anything using grit is also frowned upon for the same reasons. I always use scotchpads, I have used 1200 wet and dry but I then rinsed the pipe with a little water to remove any abrasive paste (which can act as a separating agent as it will just cook on with the heat). I will accept, it is all possibly a bit pedantic, but I do see the benefits to not using steel wool so have always just stayed clear of it for this work.1 point

-

I'd second doing all visible pipework in copper, even if other hidden pipework is in plastic. I used plastic for all the long pipe runs, as we had no water on site when I was doing first fix, so I had no easy way to leak test long runs of pipe that would end up being inaccessible. Where these plastic runs terminated, behind units, I switched to copper pipe, really just because it looks so much neater, plus it's easier to fix so that it's really solid, something that makes operating isolation valve and fitting flexible tap connectors a fair bit easier.1 point

-

@Moonshine, as @Bitpipe says, you want them on the same elevation. Could they both go out of the west elevation above your master suite?1 point

-

Good suggestion. Fascinating read: https://cleantechnica.com/2019/02/25/the-osborne-effect-on-the-auto-industry/1 point

-

You want to ensure your external vents are on the same wall face to minimise unbalancing when the wind is blowing. You also need to keep them about 1m apart to prevent the intake consuming the exhaust.1 point

-

The very first day my daughters neighbour bought his model 3 performance (7th of July or August) he let me drive it. He lets anyone he knows drive it and it is only after they have a go that they 'get it'. He's also converted a lot of people. The seats are the most comfortable of any car I have driven and they are made in house by Tesla. Apparently there are only three companies that make all of the seats of all of the cars in the world. The build quality isn't up to the high standards of some others historically but apparently they have improved, and the service isn't what it should be but the cars themselves are on a completely different level. All electric cars are very easy to drive and there is now greater choice and with the tax advantages from April it should be a no brainer, especially as legislation in the future will penalise ICE cars. And so it should too because we all like to breath clean air, don't we? I suppose at the end of the day people just like what they know but one way or another the writing is on the wall for ICE cars. Worth a Google on the 'Osbourne effect on the car industry' Could be a very expensive mistake to buy a new ICE car now.1 point

-

1 point

-

It sounds like its worth investing in a two speed unit - I've got the Smiths space saver economy one, great unit but the lack of speed control I guess is whats contributing to the noise as it's permanently on 'high'. Really does pump out the heat tho.1 point

-

Thanks all for the comments. The consensus seems like pricing isn't far off. The site has good access, plenty of space and the trees to fell are mature so ~20-25m tall. I expect they'll need some rope work for the thinning. Includes processing and stacking the firewood with plenty time to season before a fireplace is ready...Rare sunny day pic for reference!1 point

-

Since the last entry we have completed the upstairs. This area consists of two bedrooms and an open plan play area landing. Carpets were fitted after the Christmas break. Lights, switches, sockets and fire alarms have now been installed. My wife is working her way through the rooms downstairs. Painting, caulking and tidy up plastering work. We are really happy with how this is coming together. The temporary supply electrics have now been taken away and we are now wired up to our consumer unit. It’s great to be able to use lighting and sockets throughout the house. The bathroom, en-suite and utility have been ordered today so hopefully I will have some progress here in a month or so. Feels very close to being finished or being able to move in!1 point

-

They run the national scheme too, which I don't think has had any take-up. And seem to do a lot of good work in general.1 point

-

I'm a roofer and we do this on every strip and re-tile. You only strip off what you are able to felt again in the same day. Scaffolding tents aren't needed unless you are taking off all the trusses.1 point

-

I am more concerned about the dangerous human drivers I encounter on the roads each day.1 point

-

I think it would be really risky. Isn’t 6m the increased PD limit for rear extensions on Semi Detached houses? If so, planners may see that as an important ‘break point’ and going from 6.0m to 6.3m maybe a lot riskier than going from 5.0m to 5.3m.1 point

-

Did anyone see top gear and that VW electric “car”, faster than a formula 1 car.1 point

-

I used Floplast and never had any problems will seals distorting etc. The important thing is that the pipe ends are chamfered and to use a smear of silicone grease on the pipe end before assembling.1 point

-

This is nothing unusual at all. Standard detail for garage ceiling with habitable rooms above is two layers of 15mm fireline plasterboard, the pink one 15mm thick, with the joints taped and filled, and the joints of the two layers staggered. You will have thick joists for the spans you have so plenty of room for a decent amount of insulation. build in a taped air tight membrane under the floor and taped up to meet the wall air tight layers and that's your details sorted out.1 point

-

1 point

-

We used an MDPE stopcock. Toleration or Screwfix have them.1 point

-

Welcome @arg, I believe we may have "met" elsewhere in cyberspace. I believe that the PCM 34 units may be available again, after having suffered some teething troubles. @Barney12 may be able to shed more light on this. We have a 9 kWh PCM 58 unit, that now works very well, after a shaky start with a poorly designed control system. Our PCM58 unit provides all our hot water, with the majority of the energy coming from our PV system, boosted by E7 overnight, if needed. Sunamp seem to working with some resellers who aren't always as transparent or helpful as they might be, but I'm pretty sure you can still deal directly with them. I bought both our original Sunamp PV and the Sunamp UniQ we have now, directly from Sunamp, but I'm aware that they have recently contracted with maybe three or four different resellers, so I'm not 100% sure if they are still selling directly or not.1 point

-

No problem at all. Yes it was the piling company we were talking to last year. It took a long time to get our planning conditions discharged and then for the ground workers to become available. The piling guys were happy to wait until we were ready and I got the impression could mobilise on a new job within 2-3 weeks.1 point

This leaderboard is set to London/GMT+01:00