Leaderboard

Popular Content

Showing content with the highest reputation on 11/21/19 in all areas

-

You won’t get the statutory warranty under the Consumer Rights Act, and will have limited recourse to the manufacturer (you will need to go via who ever bought them for you)2 points

-

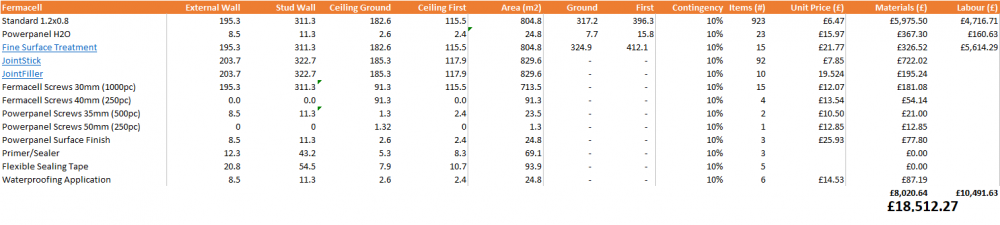

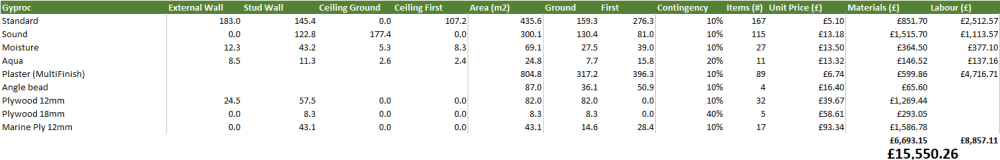

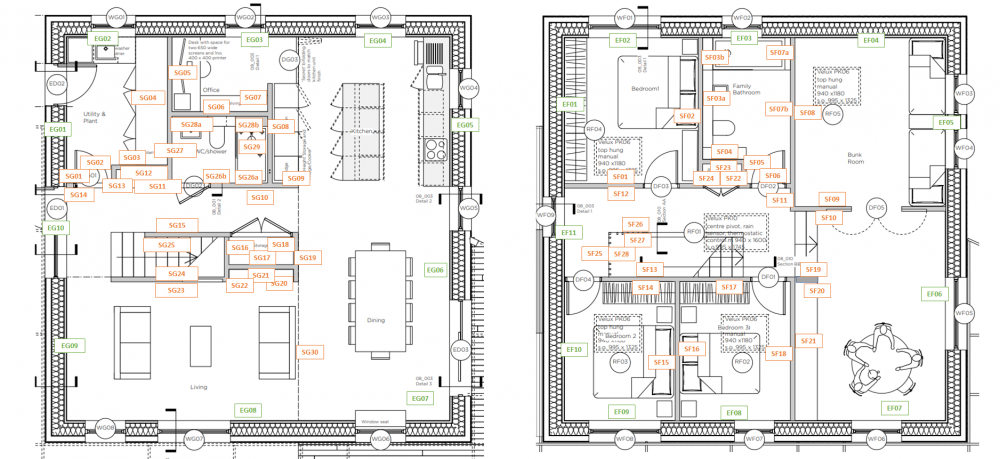

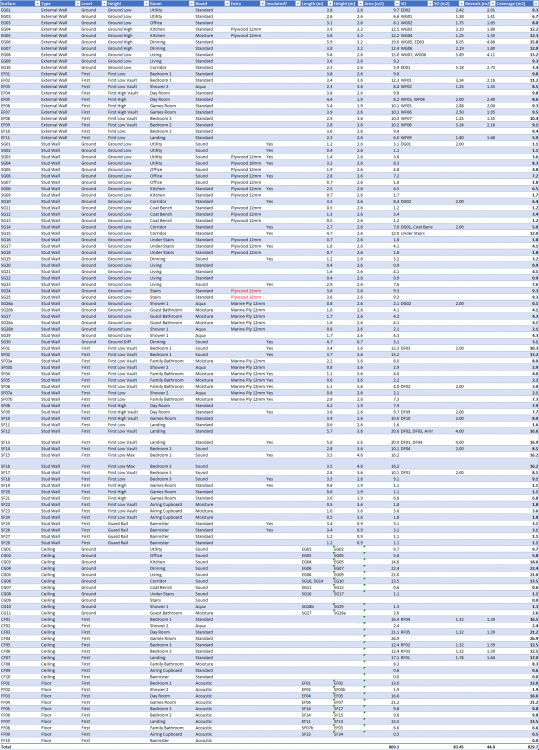

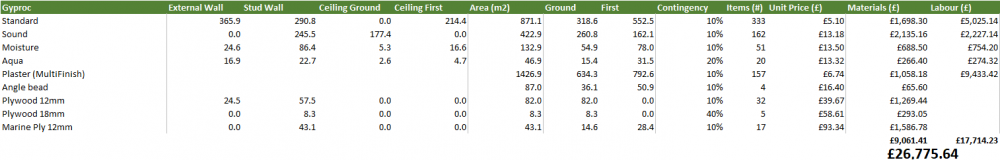

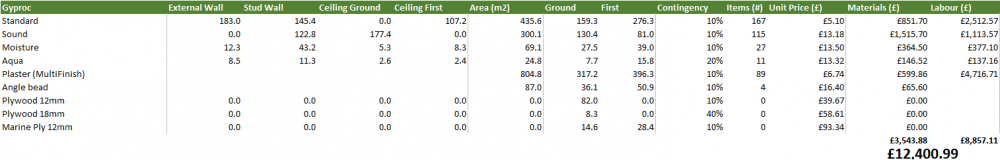

So I did the number crunching, and it looks like there is actually a good case for Fermacell if you can find a good supplier (found at £6.47/m2, making it £2.22/kg. only slightly worse than standard soundboards in my last chart). 1. Label every wall... 2. Take all the measurements... 3. Calculate labor and materials cost per m2... I've got quotes coming in at 25-33k (Double Plasterboard) - so not far off! Using only standard board I'd save ~£2k in materials. 4. Get a decent quote for Fermacell materials from here ... This is for a single layer of fermacell, equivalent density as doubled up gyproc wallboard. The labour is also an additional £1/m2 for installing these boards. The contractor also quoted more for applying the Fine Surface Treatment than skimming. 5. But what if I did just a single layer of standard wall board... This is half the density of the above except at the ground floor ceiling, and limits fixings to just areas with planned noggins or plywood backing. Using only standard board I'd save ~£1k in materials. 6. and what if no plywood backing at all... Probably the cheapest it'd get unless all the sound board was replaced with the standard board to bring it down to £11.5k.1 point

-

If the third party company will give you a guarantee on the result, then I would attach a high value to that, as getting it wrong can have a big downside. Sound insulation is pretty basic, and expensive to improve afterwards I think as it is buried deeply. So if you DIY it, then have a plan B for improvement for when the test engineer sucks his teeth and goes "sorry, Guv". Plan B might be, if permissible, to not cosmetically fit out the next one until you have sound tested the last one, so you can beef it up on the other side in Unit 2 without having to half-demolish the interior of Unit 1 to get it back to a point where you can do the work. I think you could *maybe* get some decent advice from Building Control on this, because they always want houses that work. Ferdinand1 point

-

Wood will warp in a humid environment - decent bathroom furniture is moisture resistant MDF which is more stable.1 point

-

You can have a single enclosure, with separation between the LV/SELV sides, or two enclosures, it's really up to you. @jack has a neat set up using Loxone in an enclosure that has separation, looked very neat when I last saw it, and he may have a photo of it. IIRC, his enclosure is split with the LV stuff one side and all the HA stuff the other side. All that's needed for a safe termination is something like a DIN rail terminal block. You can then connect to that as needed within the enclosure.1 point

-

It certainly does. Also smaller will have less embodied carbon and generally use less resources / have lower environmental impact. While not perfect, it does exactly do the thing you said would be fun to do (unless I misunderstood?)1 point

-

And this penalises small houses that use less energy overall.1 point

-

The final solution will be, but one response that i have from an engineer was that, in the area i am in the ground conditions are good. I am getting quotes for ground investigations and the results of these will go to the structural engineer for them to design to.1 point

-

If you are buying them and fitting yourself I think your best bet is not to ask for the VAT off as they will get confused. Just ask for their best price/discount and reclaim the VAT as normal.1 point

-

1 point

-

Quite a few times I have heard or seen people talking about how many downlights they have in a room and the numbers seem excessive. We have two bedrooms at over 4m square with 4x GU10 downlights. At its widest our kitchen is almost 10m across and it has 6 downlights across its width. If it was a 10x10 square I would estimate 36 x 500 lumen downlights would be fine depending on the brightness required. I used an on line lumens calculator to make sure I was in the right ballpark. I cannot find the one I used at the time and they seem to vary wildly on the amount of light they will tell you is required. I also used standard GU10s with the smart functions (Fibaro) built into the switches, this cost around £100 per switch, £50 for the switch and £50 to wire it up.1 point

-

I've just started on this road myself as I am in the middle of creating an open-plan 'family room' space consisting of kitchen, dining and lounge areas. Each area has different lighting requirements and I want/need to be able to control them independently to suit different scenarios throughout the day (night). I have flood wired the room with lighting cable coming back to a central distribution point which, with a 4-switch bank also being regarded as a spoke to this hub, means I can have either a traditional 'dumb' setup or something 'smart' (in both name and function ideally!). Put off slightly by the cost of Philips Hue, to start with I have picked up a bunch of bulbs, remotes and a gateway from Ikea and have been trying them out. First impressions have been mixed: + Good colour rendition with CRI's >90 + Good response from the remotes (generally; I've sometimes needed an additional button press as if the first got lost somewhere) + Seemingly good synchronisation - I've yet to end up with one bulb's brightness being out of sync with the others - White spectrum functionality of the GU10's (not tried other bulb types with this) has been disappointing - the 2700K is fine (as has always been our preference), but the 2200k has been far too orange and the 4000k (or whatever it is) far too blue. As a result we'd never use this functionality, which on the plus side means we could their cheaper non-spectrum bulbs. Despite being able to change the colour temperature, they cannot be configured to automatically warm as the light is dimmed as per incandescent (and indeed as per Ikea's cheap dumb bulbs which have this functionality). - Not sure about the aesthetics of putting four of the Ikea round remotes on the wall (which is something we'd want to do as turning the lights as we enter is something we'd continue to expect to want to do). The square remotes aren't much better and with only two buttons means you have to press-and-hold for dimming rather than being able to tap in small increments - Ikea smartphone app somewhat basic in functionality, with seemingly artificial limitations on what you can do (e.g. the number of remotes a given bulb can be bound too). 3rd party apps have been slightly better but still suffer what are presumably limitations imposed by the gateway I still feel like my itch hasn't been scratched and so what I'm going to explore next is the use of 'dumb' bulbs and use smart dimmers. The recently-released Shelly Dimmer is going to be my starting point. I don't expect smartphone or voice control to be our primary control method (but who those - I am open to my habits being changed) and so am still keen on wall switches. For this, and in the absence of many off-the-shelf options, I am looking at using a bank of four Philips Hue dimmer remotes interfaced to the system via a Pi running zigbee2mqtt and Home Assistant. Sure, my 'roll your own' approach is going to take a lot more effort to get going but it'll give me maximum flexibility - full choice of what bulbs I use (I can pick the 'best of breed' for each different type if required) and methods of control without the limitations of what the closed systems each bring. It should also be a lot cheaper given the lack of a commercial gateway and expensive proprietary bulbs, not to mention that a single dimmer can drive a whole strings of bulbs if appropriate (e.g. the worktop task lighting will always function as a group). It could of course be a massive failure but there's only one way to find out!1 point

-

I bought all my Philips Hue bits on eBay secondhand. I am trialling at present with just four bulbs, a switch, a motion sensor and the hub. Works well. I really like the idea that when I sell the house I just need to remove all the Hue bulbs, switches, motion sensors and other gubbins and leave with them all in a carrier bag or two, reverting the house lighting to a normal non-automated setup for the new buyer.1 point

-

I use Philips Hue bulbs and hub. They are a tad expensive but I’m don’t have too many of them and the convenience of being easy to source and rather idiot proof was an attraction. I use Alexa to control the lights. I can operate either groups or individual bulbs in any room from any room. I particularly like being able to tell Alexa commands like “goodnight” and it switches everything off. The only downside is the Philips hub is connected to my Virgin Media hub and if it goes down then so does your voice control of the lights. Whilst I have had a few problems with Virgin’s reliability previously I am hopeful that the recent remedial work has been successful and they are behind me now and everything is fixed and running properly. Bottom line is my set up is not the cheapest but it is nice and idiot proof.1 point

-

fair enough! Thing is ours is not passive - its a barn conversion and because of some really stupid planning laws we need to retain/rebuild some really heat zapping walls and I suspect the best we can do will be standard regs levels of heat loss.1 point

-

Part P covers the whole LV electrical installation for a new installation, so as long as all the LV feeds are terminated, inspected and tested as part of the installation, what you choose to do at the ends of them is up to you. For example, I ran underground lengths of SWA to various places where I thought I might need things outside in future, and terminated these in boxes. They were part of the installation and inspected, tested and included in the EIC. I could then add equipment to the ends of these cables without the need for any further Part P sign off, as all I'm doing is working on an existing circuit. In the case of the HA stuff, then just get LV cables run to safe terminations where you need things like contactors or whatever controlled by the HA kit, plus LV cables terminated at the SELV equipment power supplies. As long as the LV cable terminations are safe, and can be inspected and tested etc, then you're OK. You can then do all the stuff after those LV terminations in your HA box without the need for further Part P notification, as you're just working on an existing circuit.1 point

-

Same concerns and considerations here. One consumer unit similar to @ProDave's and a separate larger distribution box filled with terminals, low power supplies, logic controllers and relays smiliar to this one: https://www.hackster.io/stefaanv/building-automation-with-open-source-components-327b68 Even this configuration could be in two separate location if having space problem as I do to fit two boxes in one place. In distribution/control box, probably two sets of terminals, one for supply from the consumer unit and other for loads from the rooms and in between all the control gear. Another concern is what if I decide to sell the house or in case of automation controller failure and want to remove/replace my automation gear? Simply just take all the gears and connect directly these two sets of terminals. I was looking for the possibilities of change-over switches or terminal jumpers to make this "automation by-pass" easier temporarily in case of new installation or failure. Lets see what the professional electricians will say regarding to this separation concept and regulations.1 point

-

Point them at this https://www.heatraesadia.com/products/heating-and-ventilation/electric-flow-boilers/amptec Afaict it's a Willis heater in a fancy box with a shiny name on the outside. The installation instructions has some example schematics that may (or may not) be a useful starting point for questions here too. It specifically gives UFH as one use case.1 point

-

I wouldn't use regular GU10 downlights for such a large area. There are bigger LED downlights and LED flat panels capable of >1000 lumens.1 point

-

Or glue two layers together top one wider than the bottom. That way only straight cuts.1 point

-

If that’s what you need just make them. 150mm eps make a hot knife and cut it out. Should be easy with your German background. Oh oh hold on I think I’ve seen you with a saw. All joking aside, that looks very straightforward to do. You could make them off site somewhere warm and dry and bring to site. I think you will find some insulation co will cut to desired shape. You could even just use two different thicknesses and glue together.1 point

-

I looked into this a bit and came to the conclusion the wildlife type remote cameras was best for this given long battery life, light conditions, waterproof, etc. Some support streaming over the mobile network as well.1 point

-

I sent my “I deserve a discount” email . No reply yet . Don’t ask don’t get . My gut feeling is they will offer me 15% discount . God shines on the cheeky ?1 point

-

1 point

-

No longer a muddy building site after nearly 3 1/2 years, Hooray. Landscaping just finished during the wettest 2 weeks of the year. Never mind, it is done. Used the plastic honeycomb gravel crates with the weed membrane on the back. Lawn & wild flower meadow to sow, fencing & planting to be done, so still a long way to go, but at least some progress.1 point

-

We has 12mm OSB temprary flooring on 600 centred posijoists for well over a year. It held up surprisingly well. Just don't try putting a scaffold tower up on it without something under the legs to spread the load.1 point

-

0 points

-

0 points

-

0 points

-

0 points

-

Good point @vivienz @pocster you probably want to measure them correctly and agree the size in writing before you order, just in case .... ?0 points

-

Yes. Seems strange that the existing floor\base\foundation can't be modified. Almost as if they want these old barns to fall or burn down.0 points

-

My Dad always jokingly ask "where's my 100% discount", sometimes the person at the counter would say "sorry I forgot" and knock off whatever the standard trade discount was.... But that was the days before computers.0 points

-

Well I had my impact driver in my car and it must of been facing drill bit upwards . Went to Tesco’s bought shopping , stuffed it in my car . Got home and realised the drill bit had gone straight into 6 pints of milk in plastic container. Not a good day ?0 points

-

These were a water saving idea. They should have been a soap saving idea as you learnt the first time that there was not enough water to wash it all off.0 points

-

0 points

-

Indeed, thanks very much @SteamyTea . I'm almost feeling like getting the calculation done and then the drill out . But @Russell griffiths would laugh at me, @Construction Channel would roll his eyes, @Nickfromwales would tell me to get on with the plumbing, @Jeremy Harris would point out some fundamental errors, @TerryE would point out some rare statistical anomaly that occurs in months where there is a Friday the 13th, @MikeSharp01 would keep winding me up about the size of my drill - it's the diameter that counts , and @Pete would bring a deck chair to watch. So @SteamyTea, I think I'll pass on his one, ta!0 points

This leaderboard is set to London/GMT+01:00