Leaderboard

Popular Content

Showing content with the highest reputation on 07/19/19 in all areas

-

When flying and working on aircraft, the golden rule was to always tell everyone about any error or mistake. The only really stupid thing is to make a mistake and then keep quiet about it.3 points

-

Not sure if this is the best place for this post. I am relatively new here just made few posts and got really interesting comments. I wonder if it would be of interest to others either more experienced or beginners to meet sometimes on the self build site for a chat, learn from each other experience / mistakes / see it in real life. I am doing my project around Dunstable (Bedfordshire) if anyone would like to come and visit I would be happy to share my lessons and plans.2 points

-

It’s a good idea, all our builds have been done on a single plot with no one else around in the same predicament, this thought came to me recently when we met a couple who had been building at the same time as us but on a small development of 4 houses so they always had someone to bounce ideas off and commiserate when things weren’t going to plan and I envied them a bit, it’s a lonely place a self build and I found there was no one really who understood the process, people at work knew you were doing it but have no understanding at all, I’m regularly asked at work if I’m settling in to my new house because they think it’s like buying a new house- all ready to move your furniture into, which is usually not the case. I found this site invaluable for sounding off about something, unfortunately there are not a lot of us in a small radius up here in Scotland!2 points

-

Thanks for your comment. I've been thinking about the ICF but there were couple reasons whey I decided on the solid block work with external insulation. 1. Being my first house build and roundhouse on top there was no way I could commit to fixed design at the beginning of the project. I am a person that I can make better decision seeing the things in real than just on the drawing. Right now I built up the walls up to the windows opening and I am still fine tuning the exact locations of the windows. This wouldn't work if I went for a big contractor but because I am hands on I suppose I can be a bit more flexible. 2nd reason was that because the house had planing with external cladding anyway I preferred the idea of having the block work on the internal side and insulation on the external side (A bit of the european style:) ) 3rd reason being already unique shape I wanted to keep it reasonably standard construction for mortgage purpose. I don't know if most lenders are ok with ICF. However, when I was checking every block for the first few rows with a long timber stick sometimes I wished I went for ICF2 points

-

Scaffold down and windows in...big dose of euphoria....feels like a real milestone. We can now get a sense of the completed project. With the scaffold removed the house now looks far more suited to the plot and we hope our neighbours will be as relieved as we are. The window install went well. Our windows are Velfac and we opted to use an approved installer as it extended the warrantee to six years. It cost a bit more but the standard of install was good with great care being taken. A few grubby hand prints on the render but nothing we could not clean of with soapy water. One aspect of doing your own build that we had not considered, is the fact you start out with something perfect and new. It will slowly age and degrade. It’s akin to the feeling of the first mark on a new car. Pat and I have restored a couple of cars in the past and avoided going the whole hog of a concourse restore as it can spoil your willingness to use and enjoy the car. We just need to keep the same mind set with the build. With a house we can lock, our intention is to let the dust settle. We’ll come back to the project with fresh enthusiasm in October.1 point

-

Can we play 'Spot the Safe'. For anyone under 40, that is what we did before the Lottery came along, though it was called 'Spot the Ball'1 point

-

I've got around 25 of those left over. What would be the going rate for those in your next friendly bathroom ripoff outlet?1 point

-

Could not @Patrick make some of these Bath Companion jobbies out of his yew bush?1 point

-

I have a wall mounted basin tap, floor mounted bath filler & a freestanding bath. Really pleased with all of them. Most importantly, I also have a solution to the G & T or glass of wine & book dilemma for a freestanding bath, essential to any decent bathing experience. Wire shower caddy £19 from TK Maxx. Just the right height.?1 point

-

1 point

-

John Ward is generally pretty sound (does drone on a bit though!). As you're looking at running power to a metal shed, and as there is a risk that there may well be a difference in earth potential between an exported TN-C-S/PME earth and the potentially exposed metal of the shed, I would definitely opt to wire the shed as a separate TT installation, and not connect the earth from the house to it. The metal of the shed should also be bonded electrically to the earth electrode and earth conductors within the shed end of the installation, with no connection to the house earth, other than to the metal armour of the cable (which needs to be insulated from the shed). The logic is the same as that applied to caravan electrical installations, or an electric vehicle charge point, in that there is a need to ensure that any metal that may be touched cannot rise above 50 VAC in the event of a fault.1 point

-

1 point

-

Yes that fits all normal enclosures like an electricity meter box, gas meter box, and several types or electrical equipment cabinets.1 point

-

I'm with @ProDave on this, and would use 2 core SWA, with the armour connected at the supply end to the incoming PE and left unconnected at the shed end. Put in an earth rod and connect that to the shed and the earth block in the shed consumer unit. A simple garage consumer unit is ideal for this, as it will have an RCD plus a couple of MCBs, and you can then have properly protected lighting and power circuits at the shed end, with all the exposed metal bonded together and at local earth potential for safety. The snag with this arrangement is that you really need to have the installation tested, just to make sure that the wiring is OK and that the earth rod has a low enough resistance. However, unless you're on sand, or perhaps dry chalk, the chances are that the earth electrode resistance will be low enough. On the clay we have around here I can get around 50Ω to 70Ω or so pretty easily with a single rod. Anything under 200Ω is the general guidance, although for a 30mA RCD the earth electrode resistance can be as high as 1667Ω before the touch potential limit is reached. In my limited experience I've never seen an earth electrode with a resistance that high, though, so I suspect going without testing isn't likely to be a major risk. If push comes to shove then you're welcome to borrow my multifunction tester and measure the earth electrode resistance. It's not hard to do, and the same box of tricks will test everything else, like RCD trip times and current as well, so you can be assured the circuit's safe.1 point

-

I would not export a PME earth to a metal shed. I would treat it as a "caravan" (for the same reasons) and connect it to a local TT earth (earth rod) with the metal of the shed bonded to the TT earth. In this case you connect the SWA to the PME earth at the origin with a normal SWA gland and Banko, but use a plastic gland at the shed end so it clamps onto the SWA sheath but makes no electrical conection to the SWA.1 point

-

No, I haven't checked. It's definitely a relatively low priority task for me at the moment! Checking it would involve undoing some screws to take off a panel at the back of a cupboard in our utility room, then accessing a rodding point with a light (and possibly a camera if it's too hard to get my head up into the space).1 point

-

Doesn't seem to be a problem in practice, at least we've not noticed any variation in temperature at all. The same goes for the shower at our old house, as I fitted that in a similar way, with the mixer at the opposite end to the shower head.1 point

-

The idea wasn't mine, it came from a chap doing some landscaping work for us, who had a digger on site. We were thinking of what to do with one area and he suggested it as a secret cave. It was one step on from that to make it a location for a secure and weatherproof outdoor safe. Not hard to do, as the safe is secured inside a totally weatherproof, airtight enclosure, so the safe is nothing special, didn't cost me anything, either, as I scrounged it when it was being thrown out at work, years ago. The safe was security rated as being OK for secret and top secret documents back when it was made, so should be secure enough! Moving it and securing it needed two of us and a digger, though.1 point

-

Mine is waiting to be fitted when I tidy the appropriate location and can get to it. I loved Screwfix service when they brought their whole range of safes to the front counter for me to look at.1 point

-

@lizzie's slab is like ours, only 100mm thick, so not deep enough for a decent sized document safe. I have our safe outside the house, hidden so it's not obvious where it is. Seems to be a good location for it, as it's dry, secure and well aware from anything like fire. As a bonus, I have a spare set of keys in it, so it doubles up as a way to get into the house if we lost our keys (the safe doesn't have a key).1 point

-

Woodturners like Yew. I have a beautiful bowl turned from a yew that came down in my local churchyard in big storms in late 1990’s. If you have a local woodturner then a piece for yourself in exchange for the wood is nice. My house name plate is made from a piece of black walnut from a tree my nephew (tree surgeon) took down. It looks great and is so personal much better than a shop bought one for me.1 point

-

It looks like yew may be of some value to woodturners: https://www.ebay.co.uk/itm/One-English-Yew-wood-turning-log-blank-200-or-300mm-8-or-12-long-/252635866439 200mm long, 120mm diameter lumps going for £18 each.1 point

-

You know what the best fire wood is FREE. free wood always works better than expensive wood, tell them that.1 point

-

I clicked like but just thought I would clarify that I liked the story and not what happened to you!!1 point

-

The only potentially serious injury I had during the build was tree related. The site container was being delivered and there was a 20ft long walnut tree branch fouling the space. Was only 3-4 inches thick where it met the trunk and was about head height, more or less horizontal. Quick job with the electric chainsaw I thought and hopped up some steps to cut it. Saw went through it like butter, however rather than falling gracefully to the ground as I expected, when free from the tree it rotated and the freshly cut end smacked the chainsaw which smacked me in the face. Luckily it was not running but I got a nasty gash on my lip and some bruising. I slapped a big plaster on just in time for the HIAB driver to arrive with the container, bleeding freely under it. Once container was off loaded I headed to our local minor injuries unit to get patched up. Quite a sobering episode - now when I cut anything, I only go 3/4 of the way through and let gravity do the rest, using the remaining attachment as a hinge. Also prefer to use a Stihl hand tree saw vs anything powered as you have much more control.1 point

-

Maybe a larger lever - something that can easily be nudged with the palm of my hand. As long as the tap 'action' is as simple as possible, I think I'll be OK.1 point

-

1 point

-

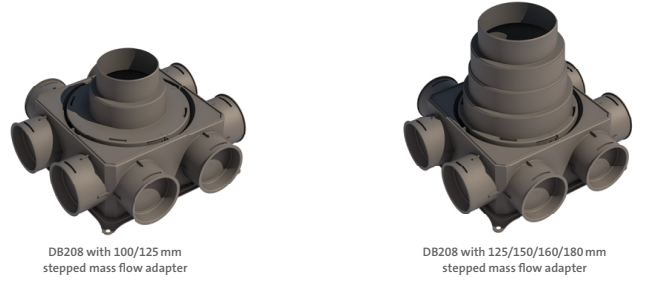

It may be possible to mix systems. The issue being that the kitchen lounge diner requires both extract and supply. Extract by the kitchen and supply elsewhere. It is possible to convert from semi-rigid radial duct-work to large bore by using a Ubbink DB208/DB206 distribution box in reverse depending on the size of duct-work: Simply connect the galvanized duct to the distribution box the run as many semi rigid lines as as required for the correct flow rate, flow limiters to balance teh system as inserted in teh main distribution box or in these adapters if required. Then run semi rigid elsewhere, doubling up as required. Not as it was originally designed but would work.1 point

-

1 point

-

What advantage does the Geberit have over (say) a Wirquin lowprofile membrane unit? Other than the brand.1 point

-

In that case I think I'd be inclined to switch from a radial configuration to a conventional rigid duct configuration for the whole house. I strongly suspect that trying to balance a mixed configuration will be a nightmare, especially with conventional larger bore ducting on the extract side and small bore radial ducting on the fresh air supply side. Whilst a conventional duct configuration needs a bit more up-front design work to get the flow rates in the right ball park, I think it may well be your best option.1 point

-

I once cut a tree down that fell the wrong way, roped and loads of tension, the tree was on the edge of a wood and I did not realise all the branches and greenery were on the outside, guess which side weighed more? Rope snapped and the tree landed on my car, horsebox, etc. Luckily there was so much soft greenery it did virtually no damage, lucky eh!.1 point

-

And there's the pity of it all. For the want of a horse the rider was lost etc. Sometimes I am extra glad I now live this side of the Channel.1 point

-

Manufacturers Instructions. Some of the syphon type shower wastes need a minimum distance before a bend to keep the water flowing and draw it out of the waste1 point

-

1 point

-

If you want down to 2mins/hour then you probably need something like this - usually used on hydroponics of all things ..!! The heat loss from a lagged 22mm pipe is negligible, it’s all a matter of cost vs convenience1 point

-

Just watched the time lapse and vids. With hindsight eh??? That was going the way it went all day long. It was slanted and weighted that way. The wedge the opposite side just helped it. The rope did jack, presume it snapped? Lesson learnt etc. Glad now that Amazon cancelled my order for a bargain chainsaw recently! ?1 point

-

The wall fortunatley isn t listed. It belongs to the council and as far as I'm aware, it has been like that since these last terrible storms a few weeks ago . But as a good citizen i am willing to put it back together myself without making a big fuss about it ?1 point

-

1 point

-

You are correct in thinking that costing your build will be easier when you have the foundations in we spent 50 k to get to slab 265 metres plus two d garages All strip 2mtr deep BB on the main hose This covered a treatment plant All drains and tank and drains for the neighbour and 750 tons of muck away and as much back in So your figures make sense Foundations will be the most difficult to product Great starting point for the rest of the build I Came in at £8000 over for the foundations But pulled it back along the way and finally Came in about 20% under budget Good luck yes it’s cheaper to install while the foundations are going in Your looking about 2k for a treatment plant It took a friend and myself a morning to install our treatment plant and next doors tank and 2 cube of concrete for each to sit in1 point

-

When I considered building a straw bale house some years ago I planned to build a scaffold around and over it before starting, corrugated roof and tarp sides, plan was to keep wet out and be able to work during rain. I went to a scaffold merchant in Bristol and he quoted me about £7k fir the scaffold and told me as long as I kept it clean and oiled it would keep most of its price and he would probably buy it back after a couple of years.1 point

-

Yes, I have my own system. Most of the work happens on a Raspberry Pi. Basically, various sensor inputs around the house get flung into an MQTT broker then some Python code reads it from there, stores it in a SQLite 3 database and serves it via HTTP (and websockets though I don't use that except for experiments, yet). Sensors talking via Wi-Fi are a few ESP8266 devices made by VAir (http://shop.vair-monitor.com/) who doesn't seem to be coming back from the break in producing these devices, unfortunately. Two do temperature and humidity in the study and kitchen. Another does temperature, humidity, CO₂, pressure and light level in the bedroom. There's also an ESP32 which I coded myself in the living room measuring the temperature there and a Sonoff TH16 in the kitchen (again running my own firmware) logging the temperature in the fridge salad tray and controlling power to the fridge (because its thermostat seems poor). Directly attached to the Pi is a DS18B20 1-wire sensor on the study radiator flow pipe and the desktop part of a CurrentCost meter which measures the current into the house (clamp round the feed between the main fuse and the meter). Part of the Python code queries checkwx.com for data from the nearest airport (Wick) once an hour and adds that to MQTT to be logged. There are also a couple of associated Python programs which query the database via HTTP. One (houseplot.py) takes the data and feeds it into gnuplot to produce the sort of plots I show on here. Normally I have an instance of this program running in the background showing the main data for the house, updated every 30 seconds, on my second monitor which is handy for lots of things, like seeing what the heating's doing or when the washing machine's finished. The other (httpreader.py) gives a more numeric output, typically a CSV list of one or a few sensor topics which can be piped into ad hoc code for more detailed looks at particular subjects (e.g., for this: https://edavies.me.uk/2019/01/continuous/) but it can also do integration, averages and so on producing a JSON result. It all just grewed and I think of it as the prototype to throw away. I like Python but it does get a bit unwieldy as code evolves and I'm currently thinking about a re-write in Rust but I need to get a bit more familiar with that language before diving in.1 point

-

Interesting spin on the cause of the demands by insurers. My take on this is that the insurers have become aware that building inspection has been a sham for years now, with poor/inadequate inspections that have allowed vast numbers of defects to go unchecked (not just Grenfell, there are stacks of examples of construction defects in housing that should have been picked up had there been a competent inspection regime in place). The private inspection companies only have themselves to blame for this situation, IMHO. Had they not been so eager and willing to sell new build sign offs with minimal inspection, in order to compete with each other for big developer business, then they would not be facing this problem. Trying to blame excessively stringent public liability insurance premiums seems to be just a deflection technique, aimed at masking the underlying problem that exists with the inspection system.1 point

-

I take it you read their reviews first ...? They sell a lot of grey import stuff that isn’t sold in the UK hence why the problem. How much was it out of interest ..??1 point

-

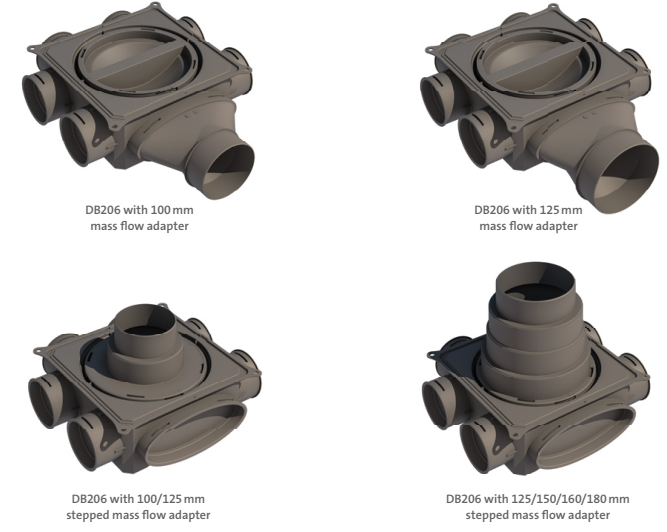

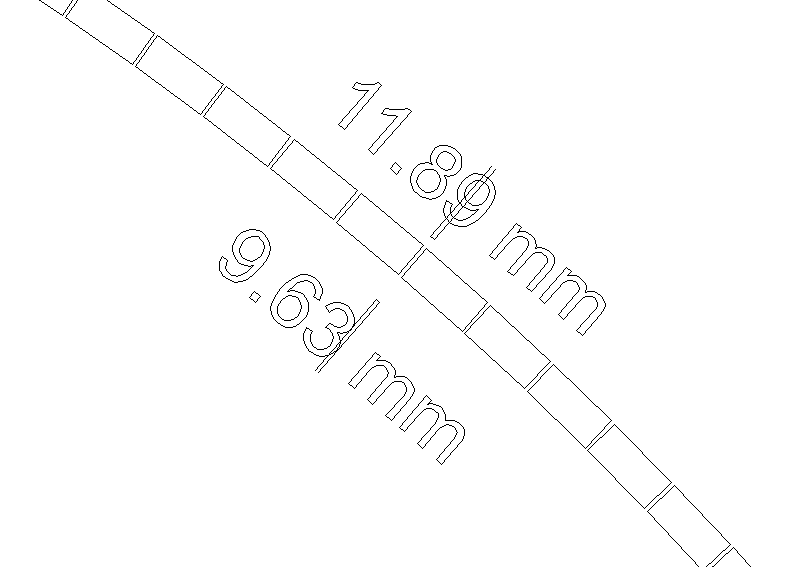

When I did a bit of radius work, we used a timber former, if the former was cut from ply you would have a plumbing point every 2.4m you kept these plumb and used the former to tap the bricks from behind until they touched the former. I still think the brickies on this will be adding a fair margin of pain in the arse markup.1 point

-

No so, you will easily get standard concrete blocks to go round with no problem and no need to cut the blocks. Given your diameter of 20m, the building circumference is 62.83m, so 279 blocks per course. The difference between the inside and outside of each perp join will be about 2mm and the maximum deviation in render thickness will be about 1mm.1 point

-

1 point

-

Geberit is head and shoulders above the rest - you’ve struck unlucky as you’ve been provided with a non-UK part as your shower tray supplier isn’t giving you the right info....0 points

-

No i've not done anything yet, had a bad time recently, sadly lost my wife to her long term illness at the beginning of June, so at present everything is on hold, because at the moment, I just can't be bothered with anything ? My main thoughts at the moment are along the lines of, 'what is the point in any of this?' can't be arsed etc etc. Doing the house up was always for both of us, but now theres just me rattling about in here. So glad we bought a 2 bed bungalow and not some larger house! I'll certainly report back when i do get round to doing this, but probably won't be for some time.0 points

This leaderboard is set to London/GMT+01:00

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)