Leaderboard

Popular Content

Showing content with the highest reputation on 06/26/19 in all areas

-

Found an article in Passive House magazine looking for people to send in parts of there mvhr intake filter to sample air quality. https://phi-architecture.com/mvhr-air-intake-filter-analysis/2 points

-

Thought i give an update on the cheapskate project and show some pictures of my office as it is finished now and I am working from there for a while already. Finishing is most definitely not up to the standard of some of you, but It serves the purpose. It s warm , well insulated and Electric heating . And it cost me approx. : 855£ BUILDING GARDEN OFFICE.pdf Timber all from demolitions Doors and Windows as well Lots of other bits and pieces from Gumtree "for free" section or Freecycle.org Had a Mate living in it for 1 Month and he gave it the thumbs up. ?2 points

-

I am prepared for some relationship tensions this evening when Swmbo helps. "No not like that, Pete W on BuildHub said like an upside down hospital corner... grrr.. didn't your mother ever teach you how to make a bed...."2 points

-

Yes. There is some concrete (dumped after the slab pour) to get out of the way. No way am I hand digging. Thanks for tips. Good idea to put the plans to the BC guy. Will get level checking pronto. thanks @PeterStarck for the pressure test info. Will look at that. I also recall @Russell griffiths Mentioning a chamfering took ages ago on another post so will look at that too. thanks all. Looks like we’ll be able to do it, with all your help ? photos will follow over the next few weeks....1 point

-

I have electric UFH With towel radiator in our en suite, only run it in the winter (but it’s on a timer/stat so will come on in cold weather), timed to come on an hour before rising, an hour before evening shower and an hour before bed to clean our teeth, only on fir a short time and it works well. You can always over ride it if you want.1 point

-

The doors were from Novellini . The company rep was an arsehole and the manufacturers literature was incorrect. As I had to get those doors mm perfect to get the two magnetic seals to be parallel, plumb and true, I was less than happy when I discovered that the dimensions in the technical literature were all one size out per line. The 720mm was on the 740mm line and so on all the way through to the 980mm option I chose ( off plan before even starting the room ) which was actually only 960mm when sat midway into the wall profiles. ? Result was the two doors fully opened and sat perfectly at 90 degrees to the walls, and the two magnetic strips sat waving at each other, 40 odd mm across from each other. Peter the Novellini rep in Swansea was a condescending prick and I ejected him from the customers house when he just started blaming me. So, long and short, check what you get BEFORE fitting it so you don’t get screwed over. I think you’ll be ok as you don’t need yours to meet in the middle?1 point

-

I suspect they might only want 'untouched' filters otherwise if they've been cleaned mid-cycle it could skew the quantitative assessment of how dirty the air is, unless they are only seeking to analyse pollutant types and not quantities (which might be meaningless given varying flow rates)?1 point

-

I think that sounds OK - unless you really are not prepared for the pour at all or VERY heavy rain causes major issues before a pour or you have an issue with moving the concrete (pump is late or not enough bodies with barrows) then I cannot see you ever being much more than 20-30mins over which for £30.00 (£36 with VAT) is not really too bad. Just make sure that you're ready a day or two before the crete is due, then check again just before the pour so that you can literally just have the guy start screwing it out when he arrives. If you have others doing the pour and finish then tell them they are responsible for any late charges which you will deduct from their agreed price if they cause it.1 point

-

Yes, I was watching the auction the other week, lots of pods, garden houses/offices etc. Started nice and low and then quickly jumped up during the last few days. I wish @Ferdinand would stop bloody promoting these auctions on here!!!1 point

-

@joe90 No idea which silicone. I had it fitted by a contractor about 10 years ago in my present house. I doubt it was anything special. I have just had vinyl laminate fitted in the new build & they have used clear silicone on the edges again. Different contractor & only in the last few weeks so no idea if this one will discolour. Fingers crossed it doesn't. If you are sealing windows internally & it is not subject to weather or excessive sunlight I would have thought you will be ok with clear. White is always a bit of a problem & yellows I find.1 point

-

Lots of practical advice here - http://www.pavingexpert.com/drainage.htm I watched our guys do it - didn't seem complicated they used a disc cutter to cut pipe & chamfer the edges and soapy water to slide the pipes in. Biggest challenge will be getting the inverts & falls correct plus the effort to dig trench, lay shingle and backfill.1 point

-

@Brickie as we are detached and a long way from the road we could put a rear extension, a side extension and a front extension. Not many people can do that as there are rules regarding setback distances from the road i suppose it would look like one big one if it wrapped all around the building.1 point

-

Clear silicone also reflects the light. I have it around the edge of my vinyl laminate flooring. It is mostly invisible but if the light catches it is shines. Forgot to say, it has never discoloured & is 10 years old.1 point

-

Concealed overflow. Think you can use same on counter top basins with syphon tube hidden in wall or adjacent cabinet..1 point

-

I used Tec 7 to seal up my shower and it is still looking good 5 years on. The only thing is it wouldn't get any direct sunshine which might be an issue no matter what one you end up using. What about using some putty instead.1 point

-

I would have thought it more common if brick to oak to use a brown sealant like: https://www.toolstation.com/window-door-external-frame-sealant-300ml/p76921?store=O2&utm_source=googleshopping&utm_medium=feed&utm_campaign=googleshoppingfeed&gclid=EAIaIQobChMI-7iy8v6G4wIVBp7VCh0i3goPEAYYASABEgIC1_D_BwE problem is the colour rarely matches exactly. But not sure how clear would look - maybe try it and see if it looks ok. For my windows (green windows and stone walls) I just jointed the gaps with mortar and this has been fine with just occasional cracking from differential movement.1 point

-

Cover the concrete with plastic as soon as you are able, so that it cures properly and you do not get surface dusting.1 point

-

1 point

-

Fold it. Pull the long edge taut, toe in the corner and take up the slack. Should allow you now to pull the middle up, then fold the excess over to the side like a reverse hospital corner and tape it you want1 point

-

Got one and love it. It’s set on a solid wood base, been there 8 years and no issue. Tap is a John Lewis tower mixer, works perfectly. Overflow is in the back of it, nice and simple. There is a 65mm hole through the 3” oak plinth, that was a bugger to cut..!! It bedded on white Unibond Sealant and hasn’t moved unless I’ve cut it off (to properly sand the plinth.1 point

-

We always have a fear of moving away from the norm and trying something new, some call it trendy, fashionable. A friend of ours was forever decorating and having the latest trends in their house and had a glass sink put in when they came in. Many months later we went round and you could see all the sealant had gone black between the outlet and the glass and the only way to remove this was to strip it all out and redo it all. Anybody got the latest black metal taps?1 point

-

Emperors new clothes (imo) I would not have one (and luckily er indoors didn’t ask fir one?)1 point

-

The few boutique hotel bathrooms I have encountered cursed with them have seemed poorly cleaned at counter level behind the basin. I would not consider fitting a counter top basin.1 point

-

Ornament. Small space, water splashes outside the bowl, fussy detail at the base. A friend had one the counter was constantly wet and laminate peeling and badly staining.1 point

-

+1. It's a safety feature and although you haven't seen anything come out of it, if something ever were to, it needs somewhere to go. G3 qualified plumber required.1 point

-

My experience with countertop wash basins is it is hard work to get the set-up correct. I planned one with a nice quartz top. Started off order this this one:- https://www.betterbathrooms.com/p/oval-countertop-basin But it turned out to have an extra underflow bit of the bottom so won't fit flat on the quartz top without cutting a big shape in the bottom. So after a lot of hassle managed to swap it for this one:- https://www.betterbathrooms.com/p/pacific-counter-top-basin Was still a hassle as was fitting it into an Ikea cabinet and I had to search hard to find correct plumbing for it. Then it got fitted but because the toilet waste had to run under the counter top cabinet, the cabinet had to have it's legs set to maximum and so the counter-top sits a little high for people to wash there face in. Also selecting the right high tap is not that easy either. I like what I ended up with, it looks great, turned out to be hard work to get there and expensive. See1 point

-

After we dismantled the bungalow we were left with 45 to 50 tonnes of mixed concrete, bricks and blocks along with around 10 tonnes of footings that needed digging out and removing from site. We finally found a groundworks company that would bring a concrete crusher to site and crush the mixed rubble from 50mm down to dust and dig out the footings and remove. We asked three companies for quotes which came in at £4320, £2154 and £1390. The only one that would crush on site to the size we wanted, rather than remove everything and bring in crushed concrete, was the cheapest so we went with them. We have seen what some suppliers bring in as crushed concrete and it’s crap. It took a day to crush around 35 tonnes of the best of the rubble and another to break out the footings and remove along with the remainder of the rubble. They were a company we would definitely recommend which was nice to be able to say.1 point

-

It's on the side of the crusher in the picture. They're a Thanet based builders.1 point

-

The genuinely most interesting offer I have seen on there this AM is 4 x 3mx7m glamping pods that look to actually be portable garden buildings that have an initial bid price of £100 each. Look like 3k or more to actually buy. Because they will cost at least £500 each to transport, could be a right bargain as home offices or site offices, as a lot of bidders will be scared. Would be a Plan B for @iSelfBuild but they are in Herfordshire. There do seem to be a lot of Shepherd Huts and Weirdy Shaped burger vans out there for cheap sale. I blame Small Spaces and Shed of the Year; Burgers at a Festival from an ex-Airstream is the 2010s version of the 1910s "escaping to Paris and drinking coffee with surrealists whilst living like an impressionist until broke". Ferdinand1 point

-

We only had the concrete crushed once which was with a 5000 series machine. They set the jaws at more than 50mm so we had to manually grade the crushed material through a 50mm mesh. If it doesn't pack up on you and there are enough of you to keep it fed then you can get a reasonable amount done. It depends how big the lumps are to start with and how small you want the final material. It is quicker to pass it through the crusher twice with large lumps than to try to get the size you want in one pass unless the lumps are small to start with.1 point

-

There are set rules on how long and how many bends it can have, and it must discharge somewhere, again within a set of rules. The alternative is to connect it to an internal drain stack via a waterless trap. You need a G3 qualified plumber to advise the possible alternative routes. You can't just ignore it. Worst case in the event of a fault it will be discharging scalding hot water to prevent the tank exploding when something has gone wrong and it is on the verge of boiling.1 point

-

We sort of did this. We wanted to go from 60m to 260m planning was not happy and said they are likely to refuse it, we asked for a site meeting where we showed them the extent that we could go to under permitted development. We explained that we could put on 3 extensions and a loft conversion over the course of a couple of years and there is nothing to stop us. Or knock it down and build a far better constructed new house. What did help was a scale model of the existing house, with permitted development extensions stuck on, then make a model of new proposed. After presenting the planner with these models he started to look a bit beaten, so told us to put it all in writing showing the exact dimensions that we could achieve under pd, it passed a few weeks later. We did use a planning consultant to do a to do a lot of leg work and it did cost a small fortune but it achieved what we wanted.1 point

-

We had them in a rented house.....I hated them both aesthetically and practically. Not to mention they are very much yesterday in style terms.1 point

-

Just in way of an update for anyone searching forum. Have finally ordered my windows, I went with Norrsken after many false starts with other companies, they have been brilliant and have managed to chamfer the frames for the bay to reduce the outside profile. Decided to dispense with bay poles as the original windows were crittal with wooden posts, if it was good enough then...1 point

-

Typo corrected. I meant -10, with 30 degree difference between in and out. Though one night this winter it did get to -151 point

-

I like 21-22, hotter than that and I start to feel it. As an aside, I don't know where the Committee on Climate Change got their recommended 19C number from (they are saying set thermostats to 19C to combat climate change), what percentage of people set their thermostats at 19C. I think this kind of suggestion totally misunderstands people, climate change needs smarter solutions than turning back the clock to when people used to be cold and uncomfortable and just heat one room in their house.1 point

-

Tat would be an interesting project. Would need some other inputs, i.e. external temperature, windspeed, shape of building, solar gain, ground temperature, rainfall. Then would need a lot of people to do it for calibration purposes. But fun all the same. I prefer Ed'd idea of letting off a stink bomb and seeing how long it takes to rid of the smell.1 point

-

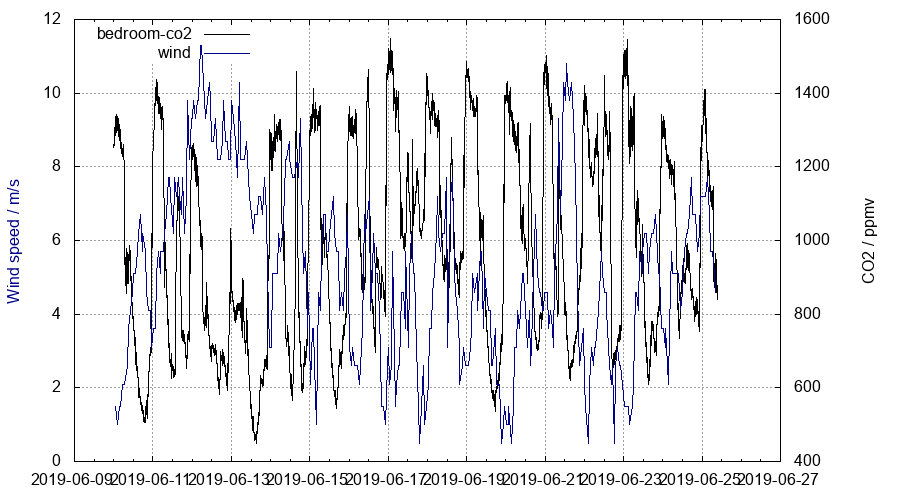

Bedroom CO₂ level (in the old house I'm staying in) and wind speed (at Wick airport, about 20 km away) for the last fortnight. I always leave the bedroom door ajar but otherwise make no effort to ventilate more than the house more than it does for itself. As you can see, roughly speaking the higher the wind speed the lower the overnight CO₂. I think with old houses if you didn't make a conscious effort to ventilate you at least got low CO₂ some of the time to recover, with a modern well-sealed home you probably don't get that much higher peak levels but you might well get them much more of the time which, it seems to me, might be more of a health issue.1 point

-

And there was me thinking it was causing bar fights, moaning about scaffolders and scratching your over-exposed hairy asres. I've got it so wrong......1 point

-

Then sit back & relax with a spritz & some stuffed peppers. You do know that’s how us brickies spend our Saturday nights,right?1 point

-

Yes, similar to me, planners did not like it at all (as they lost their appeal).1 point

-

1 point

-

M2, page 75, here covers it. In brief : exceptionally, yes, you may 'evolve' the scheme, but1 point

-

Curiously, as an ex-MoD boffin, SF generally do their own thing, and don't really put any significant pressure on defence research and development. They tend to be a bit maverick, and will go and buy their own kit, often without going through the normal procurement process, and sometimes that works well (for stuff like boots and small arms) sometimes it doesn't work at all well (like when buying helos). For example, I was being shown around the armoury at Donnington about 20 years ago, and spotted a couple of racks of AK-47s sitting in the workshop. They are pretty distinctive, as we don't have guns with wooden stocks. I asked why on earth we were servicing Kalashnikovs, to be told that it was an "under the counter" job from Hereford. Apparently these were special Kalshnikovs, accurate ones that actually shot in a straight line and didn't rattle like a tin full of old nails when you carried them. The reason I was told for SF having them was so that they didn't need to carry lots of ammunition. In pretty much any likely theatre of operation they could guarantee the enemy would be using AK-47s, so all they had to do was kill them and steal their ammo. It also used to be the case that in decision conferences (the method by which procurements are prioritised) SF always came top of the list, but that had started to change before I retired. One example I remember clearly was a 1* decision conference looking at future rotary wing requirements, where the starting point was that all SF procurements would get the highest score, and tasks viewed as non-essential got the lowest score. I was there as a non-voting observer (as I was buying helos and managing the Lynx fleet) and I clearly remember asking why military SAR was the lowest priority (the helos I was involved with didn't really have a Mil SAR role). There was a debate where one of the other 1*s present (a voting member) remarked that it cost around £2M to train a pilot, and perhaps almost as much for each crew member. When that was chucked into the equation Mil SAR went from being at the bottom of the list to up near the top, on the basis of value.1 point

-

For a two-storey box (house) with an 8x8 metre ground floor and 5 metre height the surface area (walls, ground floor, upstairs ceiling) would be 336 m². Assuming leakage of 5 m³/m²/h at 50 pascals and practical leakage being about 1/20th of the air test measurement that'd be 336 × 5 / 20 = 68 m³/h. Air has a density of around 1.28 kg/m³ and a specific heat capacity of 1006 J/kg·K so for a temperature difference of 30 K between inside and out that'd result in a heat loss of: 30 K × 68m³/h × 1.28 kg/m³ × 1006 J/kg·K / 3600 s/h ~= 730 W. I can see slightly different assumptions resulting in @JSHarris's “1,672 W at -10°C to just under 3,000 W” but not @ProDave's “worst case heat loss (-10 outside +20 inside) went from 2.2Kw up to 15.6Kw”. I suspect @ProDave is taking the 50 pascal leakage rate too literally but maybe there's something else going on. Apart from anything else, windy conditions don't tend to be extremely cold.1 point

-

Nick, any chance of a PM pls where you got these doors from + some idea of cost too for a two door kit like the pic. SWMBO and the kids well happy with the wet room corner but I don't like the albeit slight over spray that goes 1 tile beyond the falls area if you're not careful. The UFH, body dryer and venting will help I know I just want options. You know me, my mind's going off on an exotic forced air curtain / force field at the mo!0 points

-

A friend I used to work with tried to do a DIY Landrover gearbox out. Took the seats and floor out Tied a rope around the gearbox and round his shoulders, undid the bolts and started prising the gearbox off the engine. It was somewhat heavier than he expected and he followed it through the hole and ended up on the garage floor on top of the gearbox.0 points

This leaderboard is set to London/GMT+01:00