Leaderboard

Popular Content

Showing content with the highest reputation on 01/17/18 in all areas

-

As I said a couple of posts ago, I thought I'd put video updates on to save time. This one is without much detail, just a quick update on where the build is and a whirlwind tour of the house on a snowy Northumberland day.2 points

-

Regardless of the regs, it's both a poorly executed job and done by someone who lacks a bit of common sense. Being able to safely isolate anything without having to climb on chairs etc is just good practice, let alone what's stipulated in the regs. It just makes sense that you don't put a fitting like this where it's hard to get to and will probably be subjected to conditions that fall outside its design parameters, be they products of combustion, water vapour concentration, oils and fats or whatever. I don't like switch clutter either, but it isn't hard to locate switches and sockets in easily accessible, yet out of view, places. For example, the DP isolator for our boiling water tap in inside a cupboard at the top front, where it's protected from water, steam etc, far enough away from taps, yet very easy to reach.2 points

-

No down lights but a central rose might just let me poke a small camera in1 point

-

When I did ours I nailed them initially but didn't feel they were tight enough hence coach bolting. Difference when I bolted them in tight was noticeable. @readiescards. Any down lighters nearby you could use to try get a glimpse?1 point

-

Yeah I agree mate! I'd rather pay the extra for solid brass. Well, I think my plan is set. Just need my wife to get better now, so I can knock through into the extension and then start all of this work, so it may not happen this year, but hopefully it will, as that means shes better!1 point

-

The highflow range is designed for those multijet systems, so overhead + side jets + hand shower all at the same time: You have the highflow, followed by 3 selector followed by the outlets, you can select 1, 2 or all 3 at the same time, thus necessitating high flow rates.1 point

-

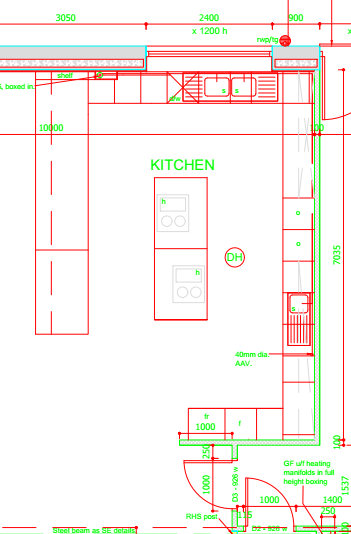

I originally planned all the isolators near the devices, meaning 13/14 DP isolators around the kitchen: 4 x Oven 2 x Hob 2 x Extractor 2 x Boiling Taps Fridge Freezer Dishwasher (scope for second slimline) Representation of the kitchen below. In the end I decided to put them all on one wall behind the hall door so out of the way but accessible: Picture below shows the bank of isolators (first fit), including Fire Alarm test point and a double socket below: These all run to unswitched outlets/connector plates for 3 of the ovens and hobs. Planning is everything, but either way that is an amateur job at best and not worthy of a "professional".1 point

-

Flex outlet where the socket is and isolation (switched fcu suitably fused) off to the side but at worktop level I favour. L shaped chase. It's in BS6172 not 7671. No I don't have it to hand. I may be able to access it tomorrow. There's something in there I'm sure about fittings not being exposed to products of combustion. That then refers to the Building Regs and the guides there come up with the 300mm rule. Now we argue I'm sure as to whether if a chip pan went up it could threaten that socket and stop you switching it off!1 point

-

The duct looks narrower than the socket so < 75mm, so shouldn't be the extractor vent imo. Ive put loads up like that, but not if recirculating. Fwiw I duct almost every one I do so they all get either hidden on top with a fused spur laying flat, or exactly as it is in that photo. If I want to not have to remove a full height chimney, to change the fuse / isolate, then I extend the supply cable and run it down to a plug or spur up high in the back of a base unit.1 point

-

If that is not a duct for the extractor what is it for, tumble dryer??? Why did he not put the plug over to the left to hide the hole the wires come out of the wall.1 point

-

Point me to a reg that says the isolator for a cooker hood has to be accessible in the same way as the isolator for an under unit dishwasher. 99.9% of cooker hood isolators I find are above the wall units off to one side. Most customers don't want switch clutter. They moan enough about having a DW switch, a hood switch joining the row would go down like a lead balloon. My question is where does that hood extract to?1 point

-

Steam and grease are the least of the worries. Have a hob fire and that extractor will be sucking it up with no immediate safe way of switching it off. I'll say no more.1 point

-

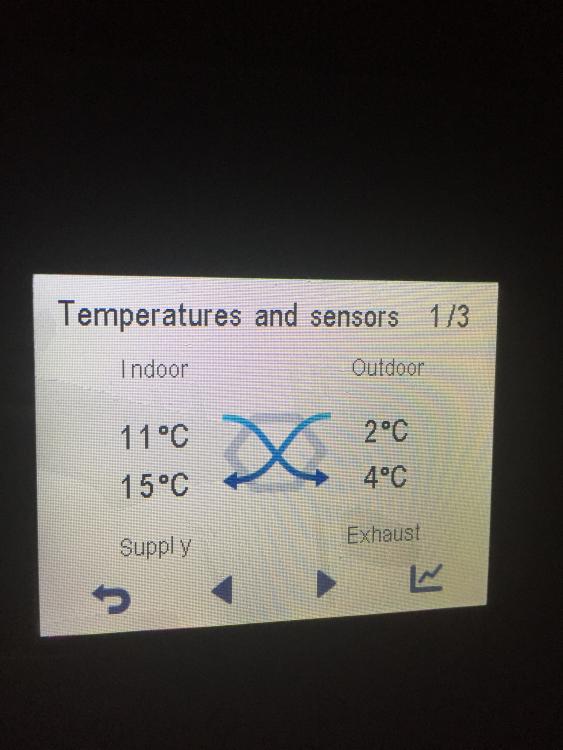

Thought the collective would find this interesting. MBC build, externally finished but nothing but bare plaster walls inside. MVHR operational but no form of heating yet in place. I have a heat battery on the MVHR intake but that’s not commissioned yet either. The temperature up up here on the moor has been pretty cold of late. Certainly close to freezing for over a week now. However, the temperature in the house seems to sit at a pretty constant 12-15 degrees. Hopefully it bodes well for future heating demand.1 point

-

I would confirm the 'plumbness' of the door before you go any further. Vertical and horizontal. If nothing else it's better than assuming - either use a laser line or a checked long bead - I say checked before I sadly found out after 3 frames and a lot of headscratching that one of my short beads was not true - which explained why I had a lot of problems (I ended up buying a small cross line laser early that was to be for the tiling, made it ten times easier if anyone else is doing this)! And check the level of the floor across the threshold too. Also check the hinges have been morticed uniformly - just in case. Best have a firm confirmation of all the above before going on any further (I suspect they will all be fine tho). If it is the floor, if you have the laser you could try work out just how much out of plumb it is - if you want to know.1 point

-

1 point

-

Those things terrify me. If just one of the 2 per rung locking devices is not latched properly, or fails, the whole lot could collapse. The very last sort of ladder I would ever trust my life to, I think they are an accident waiting to happen. Give me the loft ladder any time.1 point

-

The guy is clearly an idiot and is clearly out of his depth. To ask you to do that to a VCL shows his incompetence. As an architect I've been regularly dealing with BCOs in England and Wales for the last 30 years and I've only once or twice come across a story as bad as yours. Normally BCOs are very sensible people with a lot of common sense. (Scotland is a different matter as the system is still run by Local Authorities and the relevant departments are grossly understaffed.) If you feel the need to make a formal complaint the procedures are here: Code of Conduct link here (its a PDF) https://www.google.co.uk/search?q=code+of+conduct+for+approved+building+inspector&ie=utf-8&oe=utf-8&client=firefox-b&gfe_rd=cr&dcr=0&ei=VAUUWrn_EezR8geB_4qoCA Extract from document regarding competence: "2.4.1 An Approved Inspector shall ensure, prior to entering into an agreement for the provision of professional services, that the Approved Inspector has the necessary level of competence and experience required...." CIC complaints procedure: http://cic.org.uk/services/complaints.php1 point

This leaderboard is set to London/GMT+01:00