Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/23 in all areas

-

No, I'm on a boat, so I follow the sun. Currently in the Caribbean...3 points

-

And then the councils and the government wonder why landlords are quitting that business and there is a shortage of rental properties and rents are rising. Just the latest in a long line of "changes" chipping away at the viability and desirability of being a landlord. Milk the cash cow too hard and the cow goes away.2 points

-

Hello! We're completing a renovation and extension of an 18th century cottage in the Wye Valley, and after many Google searches taking me to this forum I thought it was about time I signed up! My girlfriend and I are managing the project and doing as much of the building and labouring as we can, with a lot of help from family and friends along the way - my Dad is a joiner and her Dad is a retired plasterer/builder. Before this house we renovated and extended a miner's terrace in South Bristol, which gave us maybe a bit too much confidence for extending and renovating a stone cottage requiring some serious groundworks and retaining walls. The extension is finally wind and watertight and we're currently doing the insulation and UFH ready for the screed. Not sure if it is allowed or not but we have an Instagram account (search Cadora Chronicles) we are using as a blog and possibly to remind ourselves of how hard it was if we start looking at other projects/plots in the future! Some taster images of the build so far below! Looking forward to getting advice from you all as we progress! The start Garage demolished and retaining walls in Majority of the externals complete! This was a couple of months ago pre glazing2 points

-

Thanks @markc I have now spoken to the roof framer. He said the best bet to gain a small amount of extra headroom whilst keeping the structural integrity would be to have ceiling joists on every rafter as usual and collar ties but that he can lift the ceiling joists up 200mm above the wall plate giving us the additional head height we need. He is quite experienced and seems to think this would be more than sufficient to stop the walls spreading. Given we only need a small amount of additional headroom, i think this would work! I hadn't really thought about what happens when you fully vault a roof and take away all the supports, but it makes a lot more sense now.2 points

-

I'd go 25mm battens minimum so you can at least get a 35mm back box in there comfortably.2 points

-

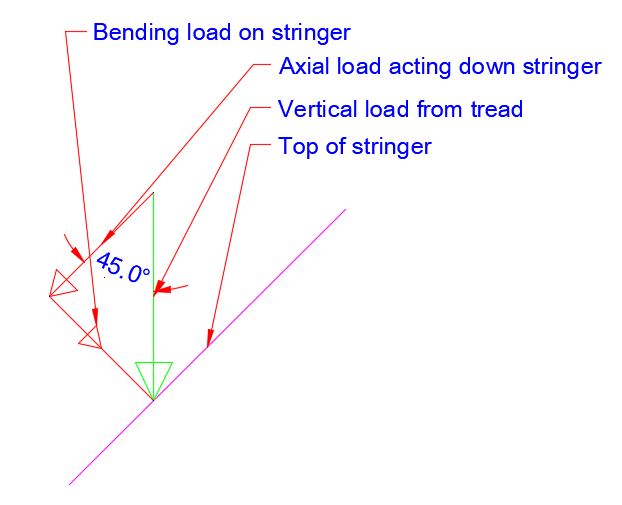

Hello all and @MortarThePoint hope all is good at your ends. There is plenty here to look at from Mortar's photo. My thoughts are this. Start with the Architectural appearance. Not sure if you are going to clad the stair like the Americans do in a high quality stable timber.. can look great and a I'm big fan of that when I get the chance... but you need a stable platform (not too shrinkable soft woods) to do this. The overall perpendicular distance from the nose of the tread to the underside of the stringer doesn't look too bulky.. do you really want to add extra material to the underside? How will that look compared with the rest of the hall we can't see? Structurally stairs are bit different as essentially they are two beams (the stringers with treads linking the tops) spanning a gap but are at an angle. The stair you have looks pretty close to the 42 deg maximum allowable pitch. Just say it is 45 degrees for ease of demonstration. Some of the basic checks we do when designing a stair is to make sure the treads (these are flat horizontal beams) are strong enough to span between the stringers, then we check the stringers and then the connections at the top and bottom of the flight. But as the stringer is at an angle we take the downwards load and convert that into it components which are a load acting perpendicular to the stringer and an axial load. The above shows the green load (you and your pals) on the treads converted into the component (vector) loads. Basically the bending force on the stinger is reduced by about 30% so that is good news as timber is very good at carrying axial loads along the grain. But what we are trying to do is get a stair that is not bouncy as well as not falling down. Beams (stringers in this case) bend in two ways.. in their plane and also by twisting.. as soon as they twist they deflect more and loose stiffness so bend even more... and then things often just get worse from there on. For BH folk! One thing to recognise here is that you can walk up a stair and feel movement.. highish frequency = "twangy" as opposed to low frequency which tends to make you nervous. My personal view.. it's actually a good feeling on a domestic stair as I think it gives it life. It "twangs a bit" but still feels safe and comfortable to walk up... that's my view for houses. You spend all that money on say other parts to bring the house to life.. why not let the stair resonate with you as you move about the house? Take a high end example say an oak frame.. it's living and moving.. why not make the stair feel "alive" My self build had a "lively stair" and it felt great.. but was still safe. I other words you can over design and make a stair dead both Architecturally and dead in terms of having a responsive house. Compare this with the stairs you go up in sports stadiums (I hope) they feel solid and dead.. but for good reason. What would you choose? Anyway back to strength and stiffness. If you take the stringers in isolation they will be quite flexible and bounce about. But the key thing is how the treads are fixed to the top of the stringers as it is mainly the treads that prevent the stringer form twisting... and thus misbehaving. The weak spot is.. and I think you have clocked this is that when the stringers dry and treads shrink they will split the stringer along the line of the bottom of the stepped notches. Now you lose all the stiffening etc that the stair relies upon. I think the split will start on the outside of the stringer away from the wall due to the treads shrinking and the way they bend.. they cause inward rotation so the split should start on the outide face of the stringer. If it was my stair I would get some 18mm marine ply and template that to the photo of the stringer away from the wall. Then glue and screw that to the stringer with structural glue say Cascamite. The screws only act as clamps while the glue sets. That will do two things. Main thing is it stops splitting of the notched bit away from the main body of the stringer.. so the tread still stops the stringer from twisting.. and the ply will also act to resist the some of the bending forces not least as you have effectively thickened the stringer. Lastly though you need to check the supports at the top and bottom of the flight. @markc As a ball park figure a domestic stair is generally desigend to carry about 150kg/ square metre on plan plus a safety factor of 1.5 to 1.6. Say 260 kg on plan to allow for a bit of self weight of the stair. Some of that will get transfered to the inner stringer fixings.. but just check your supports at the top and bottom are good enough. Hope this helps you make an informed descision. Main thing I want to know is how you are going to finish the stair, hand rails, glass? Just to add a caveat.. make sure you don't compromise fire protection etc! You may need to line the bottom of the stair?2 points

-

Lovely calm sunny day today here in the southern Hebrides and my 1.9kW PV array powered my 350W air source water heater for 6 hours, with a little spare leftover to top up the 10kWh battery bank at the same time. There was a little high thin cloud so not optimal but the array was averaging around 500W across those 6 hours. 150L tank of water started at 41C and finished at 55C.1 point

-

A PU glue will work well on polystyrene, though you would probably get away with a cheap PVA one in this instance.1 point

-

I can't disagree. But this is my first attempt, which I am treating as a learning curve. Using what I have as far as possible and the crossflow core which didn't cost much at all.1 point

-

1 point

-

Sorry for the colours just trying to help thats the way the manufacture present it I agree colourful 🙂1 point

-

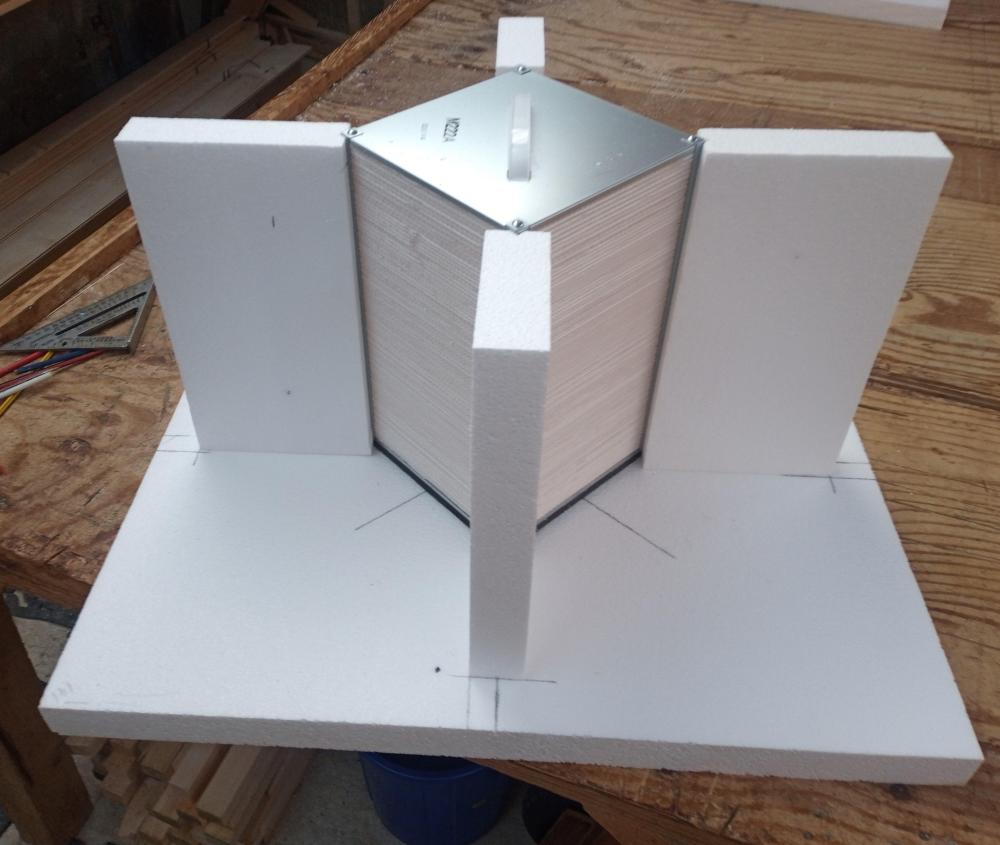

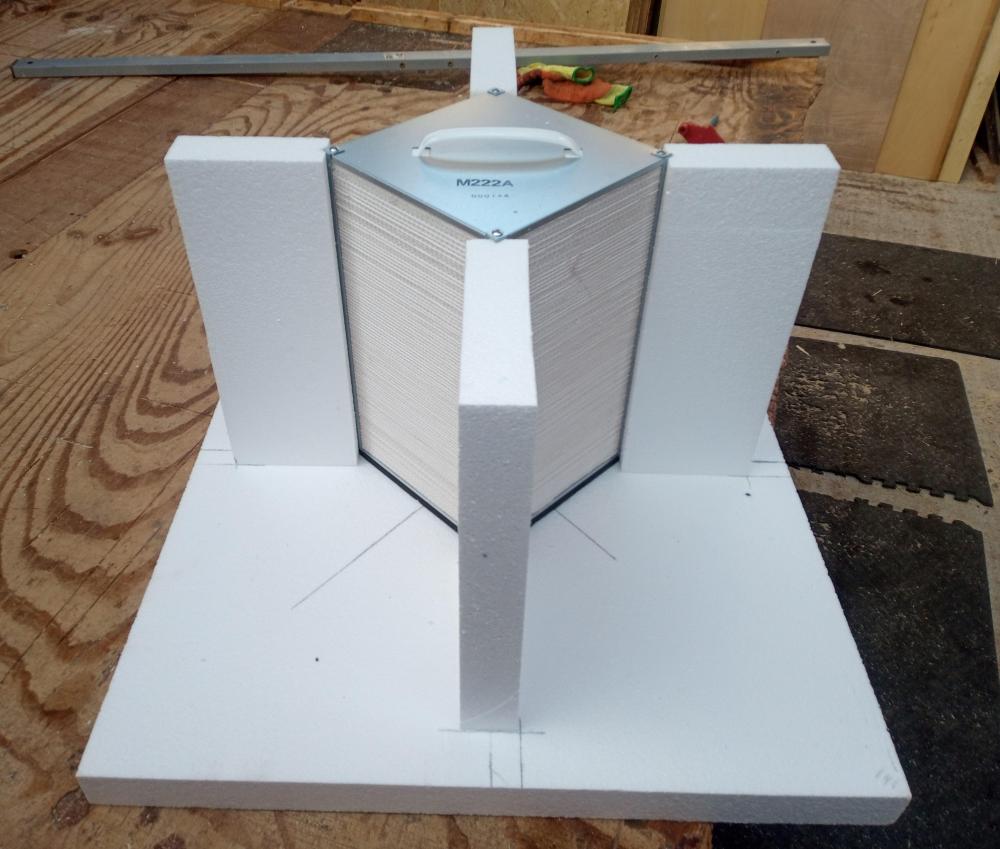

I spent some time this afternoon cutting the parts. Careful design means I get it all out of one sheet of polystyrene. Overall size is 800mm by 820. by 485. I've glued up a couple of test pieces with no more nails, and if its a success, I'll do the rest tomorrow. I'm wondering should I use dowels for added strength?1 point

-

1 point

-

I'd paint the ceiling with one of the Zinsser primers. Either the Bulls Eye 123, Bulls Eye 123 Plus or B-I-N. Think the BIN is possibly their best but that ones not water based. They also have "Allclean - Scrubable Interior Matt" top coat but I've not used it yet. They have several others worth a look. I was recommended Zinsser paint a few years ago when I had issues with paint peeling off a ceiling over a steamy shower. Its worked brilliantly for that despite frequently having water droplets hanging from it.1 point

-

If one of your tradesmen says they can get it cheaper than you, they probably can't. As they aren't prepared to spend a few hours searching around the tinternet, and will generally go to the same place each time.1 point

-

1 point

-

After @Gus Potter comments above I think that says it all, you could park a car on that 😱1 point

-

There is a Company in Ireland that sells the Cooper and Hunter version same heat pump. They also sell into UK market if you want there details PM me. I have a 9kw running for the last year being working 100%1 point

-

1 point

-

1 point

-

1 point

-

There are companies, of course, who’ll cut slate etc to a drawing / CAD file. Not crazy expensive.1 point

-

Ceiling heights would be fine for that. I'd still have though the 160 year old ceilings above. Pull up an upstairs floorboard and you're looking down on all the accumulated filth, mouse poo and skin cells that have slipped through the gaps in the boards and is sat atop the laths. Thinking "clean slate" is the best way to go.1 point

-

Knauf Frametherm 32, on a roll, easy to cut, self supporting. Makes it easy to get a gap free install. Assume to get a decent U value, you have additional insulation going into the structure?1 point

-

PS If the developer fixes your issue we can always make some edits and big them up for stepping up to the plate!1 point

-

Lots of good advise from folk on BH. Excuse the spelling and grammer. Hypothetically if you came to me I would take a different approach. Yes I know we have the party wall act etc. But why focus on that as you main stay of arguement. The PWA( England) and the law in Scotland is not strong and has a lot of gaps that can be exploited, a weak spot is ground water, flows, head and flow paths. Lets take a few steps back. You have an old house, the original part circa 100 years. I doubt it will be sitting on the sedimnetary bedrock (Greensand). In fact it surely can't be as you have an extension with 1.0m deep founds... I suspect that the extension found depth is driven by standard foundation rules from BC that applied at the time. In other words your house and extension are sitting on a layer of different soil that is underlayen by Greensand. The soil you have under is proved so far to be adequate. Now ask.. why are they next door piling down to the Greensand. I suspect it is because they want to put more load on the ground compared with the load your house is applying to the layers of soil above the Greensand and it is not working for them.. so they are piling. Now as your house is probably "floating" on the softer layers above the green sand then you need to look at what could pose a risk later. Yes you have some vibrations but for me I would want to look very carefully at how they are going to drain the site next door and if that will change the level of the ground water that could result in damage to your house. Now that sounds all a bit abstract.. but if you got me round I would hammer the developer for information on things like this and say.. your are being unsafe.. I'll report you to HSE and all the other bodies if you don't give me the information..that I need to execute my responsibility for public safety. I do a bit of Claims work against say the NHBC and major developers. They are masters at deflecting, threaten legal action.. but when you hit them on structural safety.. they have no clothes!1 point

-

I can relate to that. I'm currently living on a boat, using 1150w of solar and a couple of lithium batteries. Powers all of our needs including cooking- unless we have two dull/rainy days in a row, when we have to turn the gas on. It's possible to be very frugal with energy. Cooking is far and away our biggest power user, so when we're running short we tend to switch to pressure cooker meals or stir fries which only need a few minutes cooking. And when we have enough power, we can do a big meal (tonight was pork chops and chips, done in the air fryer). I don't know how it stacks up in terms of carbon emissions, but based purely on price, I think we must be approaching break even- small bottles of gas, as used in boats, is not cheap. It's so nice to not have to buy the stuff any more.1 point

-

Yes you are spot on. There is not much to go on in terms of the plan you posted.. but it looks like you have big open plan areas on the ground floor at that point thus horizontal stability is a key issue... can dominate the design at times.1 point

-

R290 units don't require FGAS as the GWP is so low. A professional install would have doubled the cost of mine.1 point

-

I believe @DevilDamo is correct, I enquired about this at a previous property and established that if it’s self contained (bedroom, kitchen, bathroom) it must have planning but if any one of those is missing it is ancillary (meaning you have to use the main residence for one of the functions) and this can fall within permitted development. Plus the fact who the feck is going to notice 🤷♂️1 point

-

@Gus Potter >>> you are removing huge amounts of the building that are stopping it blowing sideways, called horizontal stability This is because of the big hole for the doors? And the steels won't provide that strength to prevent 'racking'?1 point

-

Indeed. Something along the lines of: https://www.electriq.co.uk/p/iqool-smart12hp/electriq-iqoolsmart12hp I actually ordered one of these to try out in our bedroom, but didn't quite appreciate how much volume it would take up on the wall, so returned it. I also didn't quite clock when ordering that I'd have had to core drill two 180mm holes in the front of our house 😂0 points