Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/23 in all areas

-

Here be dragons. Big nasty dragons, and oceans of tears. The sums of money involved in this case are not to be sniffed at. Unless your friend has worked for you before, and you have come to know and trust his judgement and practice, may I suggest you do not employ him? Professional distance is what is needed here. Ask your mate for confidential advice, contacts, his judgment about other companies you employ: but don't employ him. All too often we hear of mates rates relationships which have gone wrong, and in my case that has happened twice. And in this case, re-read @miike , @Bozza , @Canski , @Mattg4321 hint at above. The warning signs are already there.2 points

-

2 points

-

2 points

-

2 points

-

You are entitled to your opinion. I paid a lot less than you for my kit, I got the mvhr unit from ebay and the ducting from BPC, self designed. From measurements I know I am running mine at about half the BR recommended rates and it is fine. The air is always fresh inside the house. The trouble with trickle ventilation, is a lot of the time it will be under ventilating, on a still day, but on a windy day, will be grossly over ventilating. MVHR really comes into it's own when you are building a really well insulated, and sealed, air tight house. But fitting mvhr might not always be optional. One self builder near me did a good job on sealing his house, so much so that when he had an air test done, the result was so good, building control insisted he fit mvhr.2 points

-

Well, having found this forum a few months ago and benefited greatly from the well-informed posts concerning MVHR I felt I'd like to share my own experiences and give a condensed list of useful practical tips. Unfortunately on reflection I feel compelled to write a different kind of post but still in the spirit of helpful advice. Having just DIY installed a professionally designed and supplied MVHR system in my bungalow, and looking closely at all the time and numbers I conclude that it is largely not worth it in terms of either cost or performance. I have come to the conclusion that a carefully designed system of adjustable wall, window and ceiling vents will fulfil the same needs at a fraction of the price and effort. The primary reason for this conclusion is that building regulations section F requires a continuous ventilation flow rate for an MVHR system of 0.3x the floor area in L/s. For a 100m^2 bungalow = 30 L/s. At this ventilation rate, assuming an average 21C inside and annual average 10C outside, with gas central heating, you will be saving about £200/year on heating with a 90% efficient MVHR. My experience with both this house and a previous one with an MVHR system is that you actually need only a small fraction of 0.3 ACH for any house to ventilate it adequately. Previous other posts on this forum also conclude that the required flow rate which they actually run their houses on is much lower than 0.3 ACH. The 0.3 ACH value is an outlier worst case, most owners of modern houses will find 0.1 ACH completely comfortable, even with cooker hoods and showers taken into consideration. I have personally found that about 0.05 ACH continuous is absolutely fine for a few people in a small house. If you now look at 0.05-0.1 ACH continuous you find that the heat saving per year is £30-£60/year. Out of interest I also do scuba diving occasionally and can confirm that about 0.5 L/s for one person doing moderate exercise adjusted from 10-20m pressure to 1 bar at the surface is normal. Now lets look at cost and effort. For my 100m^2 bungalow I paid BPC ventilation (who, despite what I have said are excellent in every way) about £2000 to design and supply an MVHR system for my 100 m^2 bungalow. I have very conservatively spent 100 hours planning, installing and testing the system. I have had to take paid time off work to allow building control in to inspect. I have had to hire a calibrated flow meter at a cost of about £140 including postage. I have messed about with it for many hours (about 20) to balance the system. I have spent at least 10 hours preparing the relevant documentation for Building Control. I have had to shave the bottom off all of my doors to make a 10mm gap for through house air flow and in some cases re-paint, I don't even want to think about those hours! I could go on but shall we call it £5000 if I paid someone to do all this? That's not unreasonable. So I pay £2000 and do it DIY for a £50/year payback = 40 years Or I pay someone £5000 for a £50/year payback = 100 years The MVHR unit will probably last no more than 25 years but the ducting will hopefully last a lot longer. According to the manufacturers of the MVHR I need to inspect the filters every 3 months and replace them at 2x£20 every 6-12 months. And if you are CO2 conscious lets not forget the cost of manufacturing the kit in the first place - who knows? So why did I do it? Well I got suckered into it. The last house in which I DIY installed a system like this I swapped an old heat exchanger for a crate of beer, put simple ducting and fans in about 20 years ago. I didn't need to consult building control, just did it and ran it for 10 years. It worked really well and cost me about £400 in bits and about 50 hours time. I started this new house recently and suddenly building control and the 0.3 ACH rule comes in. Still determined I pressed on to make sure my house was compliant but I should really have stopped and thought about it before I spent my £2000 on kit and began work. Are there any benefits to MVHR? Not many. I'm confident that in new build in 20 years time it will all be gone and that carefully planned vents incorporated into high quality glazing units and ceilings will be the order of the day. The only things which I can think of are filtration of pollen and pollution and maybe noise reduction (vents let in noise). If I were to do it again? No MVHR. High quality adjustable wall vents low down in the corners of all bedrooms (the rooms which you want to be coolest). Similar ceiling vents in living areas to let the air out. Bathrooms with good, possibly motorised, flap valves on the extractors. A recirculating cooker hood fan or total extract with similar good flap valve. Chase and fix drafts religiously including floors with insulating and low air permeability underlay. Hire a cone flow meter to see what's really happening. https://www.bsria.com/uk provide this service for £80-140 depending on whether you collect or have it delivered. Set the system at about 0.05-0.1 ACH On a two storey house a duct and low power fan to circulate the air top to bottom (my last house had this and it was excellent) If the layout of the house were amenable ( I have solid floors so no chance) I would probably attempt to draw air in over the foundations of the house to either pick up heat in winter or let go of heat in the summer. Follow the building regs guidelines section F which do have some good rules but don't bother telling them unless you absolutely feel the need to - it's just some wall vents in a house... Regards, David Hughes Ex F35 Lift System Stress, Thermal and Dynamics Engineer and home energy efficiency enthusiast. The Wirral.1 point

-

I'm not sure I'd still be pals with your 'mate' after that quote - absolutely wild stuff. Get some additional quotes and see where you are from there - but don't tell them you paid an architect 50k to draw up some plans for you.1 point

-

you don’t need ASHP it won’t work well in an old house, stick with mains gas. @PeterW has hit nail on head with his post. I get trades will be more expensive in London but ultimately material prices won’t be, and it is not a huge house.1 point

-

I’ve fitted copper of that size once in 30 years and it was copper waste.. never even seen it used in a domestic situation, even with ASHP 28mm is max needed. Decent flow and return backbone using 22mm Hep2O, tee off it into copper at 15mm for the rad tails if you really want to but unless it’s a 20 bed mansion and you’ve got a lot of rads, you don’t need anything none standard here.1 point

-

£11,700 for “utility appliances”..?? Decoration is £20k tops, inc inside and out window cleaner is paid in gold I assume at £335, and cleaning a full house is not £2600… Most (all..?) of your Price Sums are double a reasonable price, and given the whole thing is being ripped to bits then the £19k rewire must be using gold plated unobtainium cables … UFH in a house this size off an ASHP with 40mm of cork on the walls will give you electricity bills that make Credit Suisse squeal.. That is a £300k all in job, with decent finishes, that even with the silly London premium should come in £425k max. He’s having your pants down and your shirt off ..1 point

-

1 point

-

I bought some overpriced Loxone ones with 2.5m lead. There are packs on amazon with 5-star reviews and 3m leads. In terms of buying the real deal, I guess the best you could do is buy from somewhere like RS instead of Amazon. Putting them in UFH pipe is easy and then you can just push sensors into the pipes once the concrete is down and you don't risk the sensor lead ending up in the concrete or the sensor getting squashed or stepped on. I can't easily change my sensors as they all come up, and are connected, inside stud work and behind plasterboard, but I guess if I needed to I could get to them vs. them being concreted in.1 point

-

No. Unless you want to believe it is. One of those legends that refuses to die. It is an amorphous solid, which just means it does not have long range crystalline structure i.e. it is mixed up and chaotic.1 point

-

A fleece is around 2.5 kg and there are about 15 million flock sheep in the UK. So; 2.5 [kg] 15,000,000 [fleeces] = 37,500 tonnes a year. I have no idea how much is put in a house, but at 0.15kg.m-1 that would be 250,000 m2. Taking a relatively standard detached house, say 10 m by 8m, then the insulated area will be ~200 m2. 250,000 / 200 = 1250 houses. In England, from the start of October 2021 to the end of September 2022, 173,220 houses were completed. So; 1250 / 173220 * 100 = 0.72% could be insulated with fleece, if all the fleece was used. Now, if you want to farm sheep sustainably, you need to keep the numbers per hectare down. With some manual input (which is just importing food from somewhere else) you will be lucky to farm at 10 sheep per hectare. So; 15,000,000 [sheep] / 10 [sheep per hectare] = 1,500,000 hectares. Or 15,000 km2. England has a land area of 130,279 km2. So 15000 [land area for sheep] / 130279 [England land area] * 1000 = 11.5% of the England's land. Now it is unfair to just poo poo an idea without offering an alternative. My alternative would be to replace sheep with PV, which produces about 1 GWh/hectare. year. So 15000 [hectares] x 1 [GWh/hectare) = 15000 GWh/year. That is 15000000000 kWh, or 57,700 kWh for each of the UKs (not just England) houses, a year. I say dress our sheep up and swap them for Chinese PV modules.1 point

-

Yes 50mm 5s are fine, as is one per block. Wall plate would have been better half lapped but it is done now.1 point

-

We got a payment form HMRC today. No warning, just arrived in our account. Submission end of September. They have not paid ~£600, no idea what for but I suppose we'll eventually find out when something arrives in the post?!1 point

-

You should have drilled another hole above first, to hook the safety line. There are goggles that fit over specs. Worth looking for. I think mind came off some official "look at our project" site visit. But where are they?1 point

-

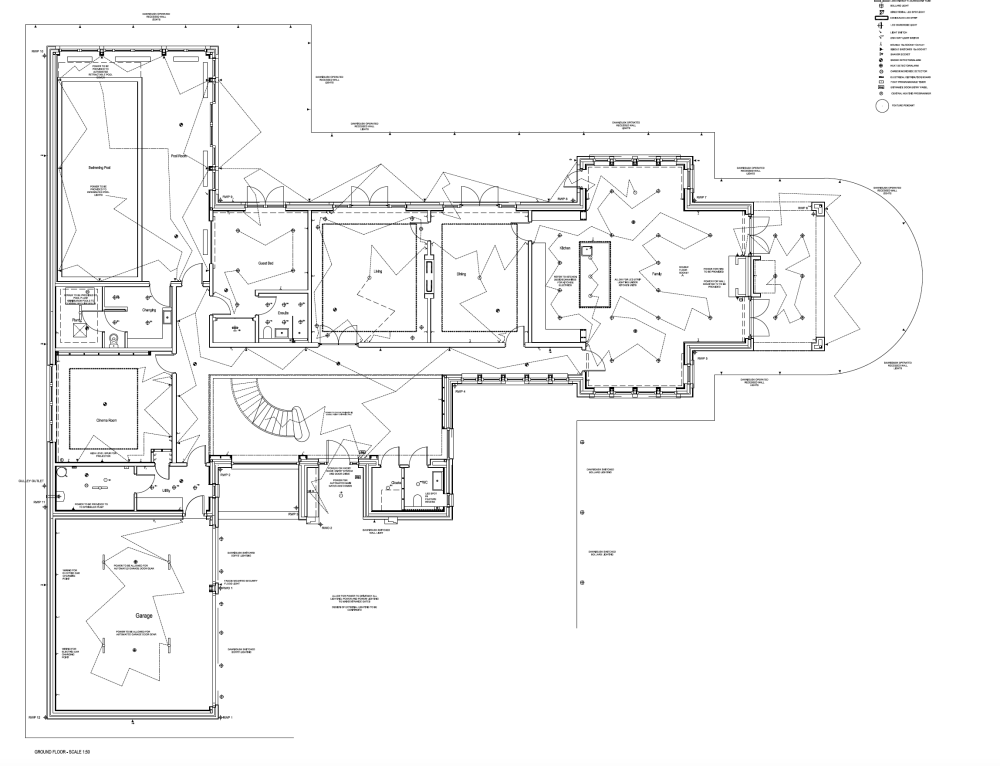

Long time since I posted these, i found one with the lighting plan n it. I did all the lighting plans myself, it took a long time - The kitchen lighting plan is correct here, there were some changes to other rooms after this. It is very dull and raining today. Yesterday was a bit brighter. 1. Lights off - Table close to windows - 170 lux. The lux level varied between 190 at the window edge of the table and around 90 at the other side, showing how quickly it drops off as you go into the room. Island - 30 lux 2. Lights on behind island and table - Table - 220 lux Island - 160 lux 3. All ceiling lights on - Everywhere in the room was between 190 and 220 lux.1 point

-

I have been struggling with this whole debacle over the last 48 hrs. I have had a response from our BC who just reiterates the Part K stuff really but also does confirm that: Providing a restrictor, such as the one illustrated above, and safety glazing is provided he will be happy - in which cases we do not need to move the transoms up. The fall protection IS needed, in our case the restrictor and safety glazing, on the GF as the BC cannot be sure how the external landscaping might be finished. The glass in the windows must meet the requirements of BS6206 or EN12150 and be marked and certificated as such. (He did not set a kN lower limit - just BS6206) Laminated glass is required in all doors and windows on the GF for security purposes. So we have crossed off all the issues - talk about stressful! Thanks for all the help.1 point

-

Not convinced it's a blown unit, really difficult to tell but it's potentially the Low E coating or just a really dirty unit inside, I'd be on the phone with the supplier and get them out to replace it. If it's not on the external or internal panes that can be cleaned it fails GGF guidelines on glazing units. Your supplier will be replacing them tbh, they'll raise a complaint to their glass supplier.1 point

-

Looks like an nursery school project, but probably nothing that couldn't come down and be done properly. Looks like a hole in the roof too...is this a renovation job?1 point

-

1 point

-

Does that window open - at all / outwards and what is the soffit made of UPVC / Wood?1 point

-

Good thread. But for the younger members from an "old crusty".. may save you money.. choice is yours. My thoughts and a bit of back ground. I worked at Torness Nuclear power station, and have designed stuff for the decomissioning of Bradwell Nuclear Station so apreciate the decomissing costs. Mostly now I do domestic stuff.. Part of my Masters was to do with the energy supply in the UK.. I started out as a local builder.. so did not go into Uni right away.. I also had a spell at designing farm buldings with 40 kW pv when the grants were good. Yes I was right into it.. how the grants worked and so on. Have to say one at least went on fire as the invertor did not do what was written on the tin. Lucky for me I was not in the firing line.. but it burnt well and no one got hurt. Yes, I'm near sixty but I still practice so have not quite turned into a fossil... and can't see me going woke any time soon. Anyway my thoughts are.. Marcro and from an SE / designer point of view looking to the future. If you are an environmentalist and into PV.. or any other home automation just to be blunt you have a living in a bubble. For the following macro reasons not least: 1/ China are becoming dominant to the extent that they are going to influence what happens in fifteen/ twenty say years time, unless they invade Taiwan.. then we will have much more to worry about. 2/ The stuff that we rely upon comes from mostly China and the "belt and braces" and most importantly hegemony that they have fostered. I also grew up in Africa and follow how the Chinese have weaved their way in that continent.. and some think the British Colonials were bad! 3/ All this stuff we are introducing.. electronics.. EV cars requires for example, mining and invites destruction of the environment.. 4/ Have you thought about getting replacement parts and how much these are going to be in say 10 - 20 years time? Remember washing machines don't last that long.. you MHVR is intrinsic to the house so should be able to preform in the long term. Do you honestly expect that you MHVR is going to last the design life of the house? You'll be lucky if it works for five years and each ear yoy need to change the filters.. Look folks you have to wake up and realise that while we are trying to save every extra penny in the UK other countries are shafting the environent and the global eco system we need to produce the "air we all breathe" You also need to recognise that you are buying filters, the running cost.. and inherant redundancy. Get your head round this. If you think strategically... The best thing we can do is to try and adapt our building systems to use the materials we have in the UK. We have lots of clay.. if we supported our Farmers and brick industry we could have bricks and wool.. good for insulation in the right combination. Also all locally sourced and provides jobs... I could list more but we have in the uk many of the things we need to protect the environment without haveing to ship in stuff. Look there is word that in the south of the UK they is Lithium for batteries.. in Scotland we have the wind to charge them up. Just maybe we could start to think.. hey... see in the south of the UK our houses are getting a bit to hot in the summer.. can we pinch ideas from Adobe houses that rely upon passive stack ventilation. Yes there is a bit in the building regs about this but if you think about it.. it's a controlable chimney. They do it in Spain for example just here BC don't help. Anyway.. kids need fresh air not filtered air.. just think about it if you are a parent. Yes you may think I'm off the mark here.. but see in ten years time when you can't find replacement parts for you MHVR and home automation other than from China. I'll get the last laugh.. if I'm still here. If not well you made you own bed. I have a house with UF and some nice bells and whistles.. but these come at a cost.. there is not a couple of weks that goes by when something does no break down.. You'll end up saying.. the house was great for the first month.. but there are loads of things not working and it is getting on my tits. When I go to see a Client I point out the good bits and the bad.. For example just this weekend two dimmer light units have failed out of about 16.. and that is in the first 18 months of installation .. and they have to come from China. I can fix this myself but what if you are not OK with diving into electrics.. how much is the spark going to cost you? To finish.. I'll appeal to your wallet. Do you think that having MHVR is a good or bad selling point? Can you demontrate to a buyer that it all works, what value is a Surveyor going to attach to it.. is it like a dodgy gas boiler... at least a gas boiler has a Gas safety certificate .. your MHVR just has.. cowboy written all over it!1 point

-

@eandg, yes, but our design was simpler as our windows were similar sizes between ground and first floor so butting the 'on board' sections up to the reveals wasn't so difficult. You sound like you might have a trickier situation, but I'd imagine with some careful planning you should be able to get it to look ok. Differences in the spacing are only really visible if you look hard enough, at a distance I think it looks pretty consistent, even when it isn't. @Jenkisee if these help you. The change in spacing is quite clear if you look hard enough, but it doesn't bother us, functions fine and nobody mentions it!1 point

-

From Natural England: Thank you for completing Natural England's complaint form received by the Complaint Resolution Team on 17 March 2023 regarding you [sic] Great Crested Newt and District Level Licencing. We take all customer complaints seriously and are committed to fully investigating any issues you have raised. We will aim to provide you with a full Tier 1 response by 11th April. If our i nvestigation [sic] is taking longer than expected, we will notify you and provide you with an update. Details of our complaint's [sic] procedure can be found at: https://www.gov.uk/government/organisations/natural-england/about/complaints-procedure. I'm going to lodge my planning application, and if the DLL licence needs to be implemented I'll continue arguing the case for the methodology to be changed. I'll update the thread when appropriate.1 point

-

I got a letter this week from HMRC DIY team to confirm receipt of my claim- which was submitted 3.5 months ago. Said they will endeavour to process with 6 weeks.1 point

-

Got mine paid in full 1st week in March, so that's just under 6 months. But judging by recent posts they are better staffed now. We were meticulous with our invoices, went through them 2-3 times before submission to ensure they met the criteria. Sadly, excluded about £2k's worth on this basis, we had tried to police this when buying but with the stress of the build its inevitable we would drop the ball on a few occasions. But, it was paid in full with no queries. Now, the only question for me is should I have waited until final BR sign-off, which was 5 months after occupation? We had a fair amount of expense over that period, so lost out on VAT reclaim monies. But we were paranoid about the 3-month window and whether they would insist it was from moving in date ..........1 point

-

I use these on all the extract ducts https://www.epicair.co.uk/products/extract-air-valve-filter-for-8960-125mm-valve-10-pieces1 point

-

1 point

-

"Floor? Not sure but my googling says this may be up to 1.2. Does this sound right? - If so, I guess the windows don't make sense to go for the extra £4k." Search Floor Perimeter/Area ration for an expl of how floor U values are calculated. This site (https://warmafloor.co.uk/support-centre/u-values/) has a good explanation. Not sure that in actual 'comfort' performance it's going to seem the same for a solid floor as for a (ventilated) suspended timber floor.1 point

-

We moved from Manchester to Cornwall 6 years ago and we are very happy with the overall location. Our existing converted barn, was converted by the previous owner and is very nice but is built on three levels and has 4 double beds, kitchen, dinner, lounge and snug and 3 baths so it is far too big for us when we retire. When we bought the house I always say we chose it for the working barn apx 300m2, not the barn we live in. We are building for our future in the hope that we can continue to live her a long time, if it takes us 10 years to build we will be 65 when we move in. My husband has a history of bad backs a bungalow with no steps and easy access is high up on our want list. More recently our Greyhound is refusing to go down to the snug in the lower ground floor at night preferring to stay upstairs in the kitchen. He is incidentally another reason we bought the property, two fields he can run off lead. We don’t want anything too large, a well insulated bungalow that will be cheap to run and maintain. We have a small cow shed on our land and although our property is listed the cow shed is outside the curtilage of the property and built in the 70’s so does not require any listed building planning consultations. When we purchased the property a new build was never on the agenda, but it is now. In September 2021 we engaged the services of a planning consultant with a view to demolish the small barn and replace it with a new build, his view was favourable. In January we then approached an architect who suggested full plans would be best since what we were asking for was in keeping with the surroundings, not that much larger than the existing barn and since it was visible from the listed property more detail such as windows and cladding would be required. Two months of absolutely nothing happened then in March we met up to discuss our requirements and finally in May we submitted our plans. In June we had our necessary bat and bird nesting survey, the gentleman who conducted the survey nearly started looking at another old stone barn until we corrected him and he then told us that bats wouldn’t like the old cow shed as it would be too hot in summer (tin roof) and too cold in winter due to the holes, drafts, and thin wood walls. Then in August we had the Phase 1 preliminary risk assessment, required because we were previously farm land. From the survey I learned that in 1884 there were two wells 165m W of the site another 580m SW of the site and two quarries quite a distance away and in 1906 a smithy in the village, no surprise there as there is a house called ‘The Old Smithy” . The geological map indicates that the site is underlain by the Bude Formation - Sandstone. Sedimentary Bedrock formed approximately 310 to 319 million years ago in the Carboniferous Period. The report was very detailed but returned very little about the land the barn is occupying, that a visit to site wouldn’t tell you. Nothing bad was reported so we were happy and we continued pushing more paper around. Eventually its our turn for the case officer to look at us in detail and we get conditional approval in mid October 2022. Mid March 2023 and we have submitted our building regs drawings and my Part O Spreadsheet, window amendments to the planning department and the SE has quoted and is starting on his work. We are over 150m from the fresh water main so will need chlorinating. I found a great guy who has dug the first trench for the Water, Electric and Openreach, he will return when the new build is ready for the second trench to install the services into the house and will then chlorinate the pipework. Site electric is in from the pole in our neighbours yard towards the Old Cow Shed. We were offered a good price by National Grid for 3 phase, they would have struggled giving us single phase due to lack of supply network and another new build close to us in the village has gone off grid because there connection fee was too expensive. We wanted 3 phase any way as we hope to fill the roof with 30 solar panels facing SSW with no shading. As soon as it warms up and the field is firmer we plan to start clearing the site and moving the spoil down the field into our larger field. Doing it now would be like making a mud bath. Sometime between October and February we will demolish the barn and this time next year the new ICF build will go up. In the meantime lots of planning continues and I’m going on a short plumbing course. The husband is an Electrician by trade and can do some plumbing but hates getting down on his hands and knees now. Last year I tanked and tiled our existing en-suite and have learned all about wet wipes and silicone so another job moved from the husband to me. 😀 The main photo shows the site electric and the drive leading up to the cowshed to the left at the end and just on the edge of the photo are the old stables used as workshop storage each stable bay has a different items stored. A new entrance to our field will be made diagonally from the site electric to the left of the old cow shed which will make our farmer happy as he currently has a very tight turn left just in front of the cowshed. He comes twice a year to cut the grass and in return he usually takes at least 15 round bales away. The other images are from the architect but are already out of date. To pass Part O we are submitting an amendment for the removal of 4 windows on the North elevation and replacement with 6 roof windows that offer more ventilation. Costs to date Planning Consultant £600 Council planning application fee £500 Bat and Bird nesting survey £370 Phase 1 preliminary risk assessment £740 Architectural Design and planning £3000 Building regs Drawings £1250 SE £900 Trench and ducting etc for Water, Electric and Openreach £2830 Site Electric £2470 Openreach cable and ducting £0 Total £126601 point

-

In that case you'd use a rainscreen design. Battens fitted with 150mm galvanised screws, cement board to the battens, then your slips. Obviously a bigger cost, but has other advantages (don't quote me, vague memory from reading a passive house + article about the rainscreen design being preferred option for EWI structures.)1 point

-

UPDATE: After another attempt with a couple of new Cobalt drill bits, I hired a mag drill and bought the relevant bit for that. Hired it for a days - actually returned it at 11.45am!!1 point

-

I have a similar set-up. A few comments: We completed our self build in 2020 and have a home with a good level of insulation. I did'nt need the cylinder to do space heating for us. We have three extract points, en-suite, bathroom and utility room. As a way to provide domestic hot water heating for a family of four, the capital cost is cheap compared to getting an external heat pump fitted. Our tank and system is a Joule Aero, with stainless steel cylinder, no need for anode changes. I believe they have now released a new model. I live in soft water area. The system also has a dual immersion electric heating, but never used it and rely entirely on the mini heat pump. All in we are about 10-12kWh of electricity each day, but not sure how much of that relates to the heat pump. I'm not sure why the system is not popular here, when I posted a few years back, one member suggested that I would hear whistling through our trickle vents when the system was running which was nonsense. After living with the system for coming up to two years, I'm so glad we fitted this system rather than external air source heat pump, as it fits our circumstances well.1 point

-

The bottom line with regard to whether or not MVHR recovers as much waste heat as it could has to be related to airtightness, even if there is anecdotal evidence that sometimes this doesn't seem to be the case. If the house leaks air, such that the MVHR is effectively bypassed, then the house must lose heat from that bypass ventilation. Whether that heat loss is significant depends entirely on how much air leaks into/out of the house without passing through the MVHR., relative to the proportion that does pass through the MVHR system. Not only is airtightness a factor, though, location and environmental conditions are too. Taking our location as an example, we get few days in the year when there's much of a breeze flowing past the house, because we're in a relatively sheltered location. As such, our airtightness could probably be a bit worse than it is and the MVHR would still work OK. The other factor relates to how much heat is lost through the fabric of the house relative to the heat lost through ventilation. If the fabric heat loss is massively greater than the ventilation heat loss, then fitting MVHR may not make a big difference overall, as it can only ever reduce the ventilation part of the heat loss. Again, in our case the house fabric heat loss is pretty low, so ventilation loss would dominate the total, if it were not for the MVHR.1 point

-

You need to look at it in terms of what aspect of mhrv is the most important to you. In my case it's the clean fresh air. I have had sinus issues for a long time so moving from a stuffy old 1960s house with its fair share of condensation and mould to my new build was a massive leap. I couldn't really care less if it recovered any heat to be honest. Once a year I spend about 30mins changing the filters and washing and drying the heat exchanger and the rest of the year it just works away doing it's job.1 point

-

We have 48 spotlights in our ceilings. Not one of them has been sealed as there's no need to. If you have air leakage from outside to your ceiling voids then you're already fighting a losing battle, surely?1 point

-

Welcome David. I'd urge you if you can to visit a passive build. The feeling is odd coming from a traditional house. Warm, totally draught free and quiet. Fitting MVHR to a passive place and yours, well there's really no comparison. Have an air tightness test done, I reckon it would shock you. Your place doesn't have an airtight, thermal envelope by design so you've multiple leakage points and thermal bridges. Snap btw! ?1 point

-

Have you look at the times when you are heating? (and maybe cooling) Or are you assuming that anything below a fixed external temperature is a heating time? (just about to turn my heating off as it has gone above 10°C)1 point

-

I am like @ProDave, cheap unit from Ebay, self designed, self installed (yet to balance it, other things tend to be more important) BCO simply looked at the vents and said “no trickle vents because you have MVHR.” and didn’t ask fir any paperwork ?. We live in a very windy position near the coast and any trickle vents and such would whistle loudly. I am glad I installed mine.1 point

-

I'm happy to go for it just so I don't have trickle vents. Why would you install reasonable/good/excellent glazing and then put a big hole over the top of it?1 point

-

Speaking as someone whose MVHR was broken down for a few weeks in a highly insulated and air tight house (0.25 ac/h) I strongly disagree on the ventilation aspect. You've also largely ignored the HR part of MVHR. My MVHR is now fixed and I'm very pleased.1 point

-

The MVHR in our home has, quite literally, transformed my wife's life, and probably added years to it. Frankly I don't give a damn whether it ever pays for itself in a financial sense.1 point

-

MVHR...less dust in the house, less pollutants like radon, off gassing from furnishings and carpets, people on here with allergies report benefits, mould issues reduced, constant fresh air.1 point

-

I'm unaware of the problem Terry had with the Stroma software, TBH. If I had known of it I'd have highlighted it as a potential gotcha with that software package. Out of interest, what was the glitch he found with it? We're all entitled to our view, and to express that view, be challenged on it, and defend it. Why should I, or anyone else, change our view just because someone disagrees with it? Readers and contributors to this forum are free to take heed of, or ignore, anything here. Not only do I have no control over that process, I most definitely would not wish to. All I will ever do here is put forward ways that people can do things, or research how to do them. If they choose to do the same, then that's their decision. If they choose to ignore it and do something else then that's also their decision. It's just about informed choice, and providing as wide a range of information as possible, from as many contributors as possible, so that people can choose which path they wish to take.1 point

-

With respect, I'm an ordinary person, entirely self-taught when it comes to building-related stuff, so I feel perfectly entitled to give my honest opinion as to what can be done by someone who wishes to take the time to research and learn. I fully understand that some may not want to do this, and may prefer to just stay in the dark, consider this stuff to be something beyond them, and pay to have it done for them. That's fine, that's their choice, but if we don't at least make it clear that there are ways to do stuff yourself, rather than pay someone to do it for you, then what use is a self-build forum? We may as well just become a review site, sharing recommendations for professionals to hire. In the case of a SAP assessment, all of the data the assessor uses comes from the self-builder anyway. If you hire an assessor they will not ever visit the house to see what was used in its construction, they will take your word for everything. I cannot see the difference between sending a set of drawings, together with fabric build up schedules, an air test report, specs for the MVHR, hot water system, heating system, controls, glazing etc to an assessor and putting that same data into an application yourself as a backstop check that the design meets your own expectations. I refuse point blank to stop suggesting ways where people can do relatively straight forward jobs themselves. I believe that the more people know and understand about their projects the better equipped they will be to make sound judgements, and if some disagree with that ethos then they are free to just ignore it, aren't they? By the same token, if someone just wants to pay professionals to do the whole of their build, then that's fine. There are just as many pitfalls from taking that approach though, as some here will probably attest ( @lizzie springs to mind with the problems she experienced with using a professional project manager, professional (and expensive) window supplier, professional (and expensive) MVHR installation, to name just a few).1 point

-

We had no problem doing this. I used the free version of the Stroma FSAP software to check the design and produce the design stage assessment, and I just updated this to reflect the as-built changes and emailed the file to an assessor who checked my work, produced the as-built assessment, lodged it on the database etc. The fee for the as-built only work was modest, about £100 plus VAT. There's no requirement for an assessor to do the design stage assessment, I get the feeling from chatting to BC that it's primarily a sensible check done at the start to be confident that the design meets or exceeds the requirements, so really an assurance tool (albeit a very important one). Nothing happens to the design stage assessment, it doesn't get filed or lodged on a database anywhere, as fas as I'm aware. It's only the as-built assessment that has to be done by a registered assessor and lodged on the database as a record of the performance of the house when it was completed. The big advantage of doing the design stage assessment yourself is that you get to learn a fair bit about how SAP works, what makes a significant difference to the outcome, and what doesn't have much impact. That makes it a really worthwhile exercise, as it's usually relatively painless to change a few things at the design stage, whereas that may not be the case later on in the build.1 point

-

Point of principle, really, at least as far as I'm concerned. In my case, it has little to do with whether it's cheaper to get someone else to do something, it has everything to do with the view that was embedded into me when I was a small boy: "Never pay anyone to do something that you can learn to do yourself" One of the greatest failings in our society is that we are gradually losing the confidence to do things that we are perfectly capable of doing, with a little bit of effort and application. Self-build is a perfect opportunity for those that wish, to spend some time learning and perfecting new skills. There isn't much in life so rewarding as looking back at something and knowing that it was your own efforts that made it happen. There's nowhere near the same sense of achievement from just paying someone else to do something.1 point

-

Hi dave. Deffo run a 110mm soil pipe to the foul network outside ( NOT the rainwater ) and reduce to 50mm after the 110mm rises above the slab. As it’s a kitchen sink not a bath / other I’d avoid running anything smaller bore tbh. You could go for 50mm but then you have to have the reduction done underground outside which isn’t great. When the 110mm rest bend turns to vertical your pipe will be pointing up out of the slab. Get a 110mm x 50mm reducer and take that immediately into a 50mm Y branch ( T ). Into the 45/d off spur of the branch you put the sink etc and the vertical 50mm outlet of the branch goes to a rodding eye for access. I’ll do a pic in a mo.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)